Method for zero emission treatment of desulfurization waste water based on flue gas waste heat evaporation

A technology for desulfurization wastewater and treatment methods, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of failure to be widely promoted, high investment costs and high energy consumption in operation costs, and achieve simple process , reduce membrane fouling and clogging, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Approximate terms in the specification and claims are used to modify the quantity, which means that the present invention is not limited to the specific quantity, but also includes acceptable modified parts close to the quantity, without causing changes in related basic functions.

[0042] The method in the embodiment of the present invention can be used for zero discharge of desulfurization wastewater or zero discharge of high-salt wastewater in different industrial processes such as electric power, metallurgy, and chemical industry.

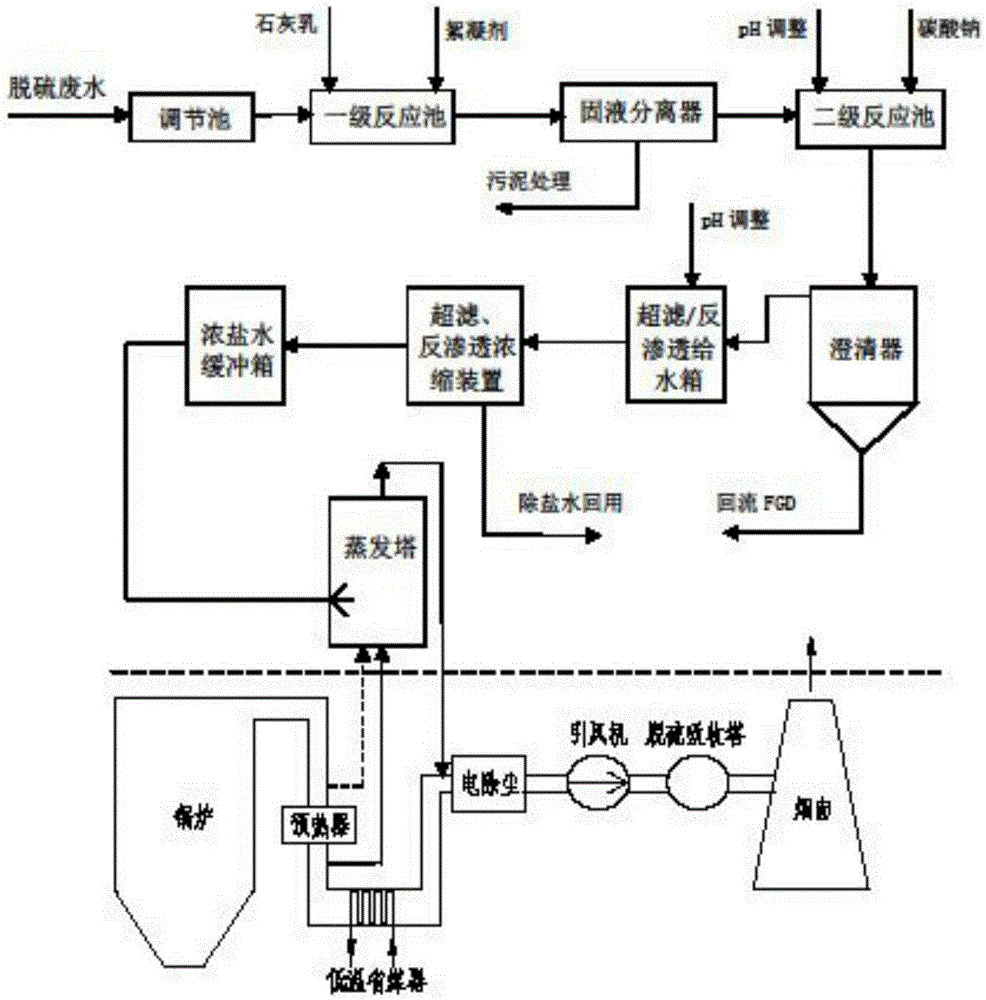

[0043] The characteristics, composition and advantages of the present invention can be better understood with reference to the detailed description and with reference to the accompanying drawings. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] The invention provides a zero-discharge treatment method for desulfurization wastewater based on waste heat evaporation of flue gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com