Hypersalinity mine water desalting device and desalting method

A high salinity and desalination device technology, applied in chemical instruments and methods, general water supply saving, mining wastewater treatment, etc., can solve problems such as increased investment and treatment costs, membrane fouling and clogging, high salt content in concentrated water, etc., to achieve Effect of reducing membrane clogging and prolonging membrane life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

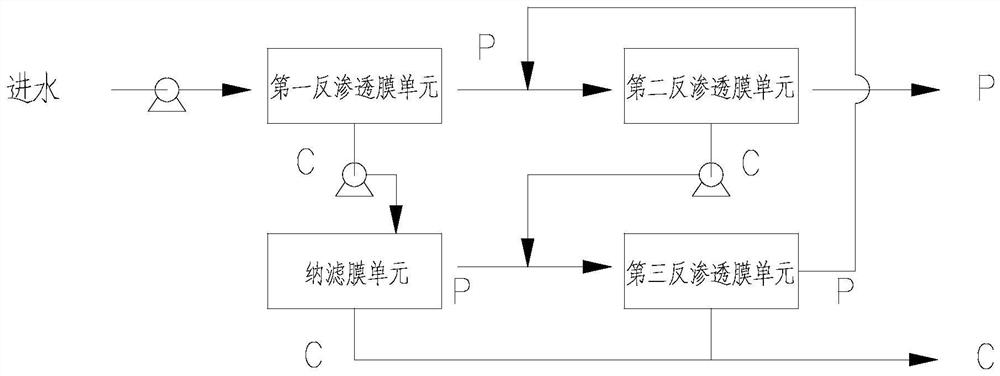

[0032] Such as figure 1 As shown, a high salinity mine water desalination device, the desalination device includes a first reverse osmosis membrane unit, a second reverse osmosis membrane unit, a third reverse osmosis membrane unit and a nanofiltration membrane unit;

[0033] The water inlet of the first reverse osmosis membrane unit is connected with high salinity mine water, the water production port of the first reverse osmosis membrane unit is connected with the water inlet of the second reverse osmosis membrane unit, and the concentrated water outlet of the first reverse osmosis membrane unit is connected with the water inlet of the second reverse osmosis membrane unit. The water inlet connection of the nanofiltration membrane unit;

[0034] The concentrated water port of the second reverse osmosis membrane unit is connected to the water inlet of the third reverse osmosis membrane unit, and the produced water of the second reverse osmosis membrane unit is qualified and re...

Embodiment 2

[0038] High salinity mine water (a type of mine water produced during coal mining, the salinity (total content of inorganic salts) is greater than 1000mg / L) is pretreated (decarbonization and activated carbon) and enters the membrane desalination system. The waste water of this system first enters the first reverse osmosis membrane unit through a high-pressure pump, and the recovery rate is controlled at 65% to 70%; the concentrated water of the first reverse osmosis membrane unit enters the first nanofiltration membrane unit through a circulating pump, and the produced water enters the third Reverse osmosis membrane unit; the recovery rate of the first nanofiltration membrane unit is controlled at 70% to 80%; the concentrated water of the first nanofiltration membrane unit is discharged and collected, and the produced water enters the second reverse osmosis membrane unit; the second reverse osmosis membrane unit The recovery rate of the second reverse osmosis membrane unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com