Resource recycling method of byproduct mirabilite

A technology of resource utilization and mirabilite, applied in artificial filaments made of viscose, electrolysis process, electrolysis components, etc., can solve the problems of reducing the service life of the membrane, low concentration, increasing the membrane resistance, etc., and achieving a long service life of the membrane , Low pretreatment requirements, and the effect of improving the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

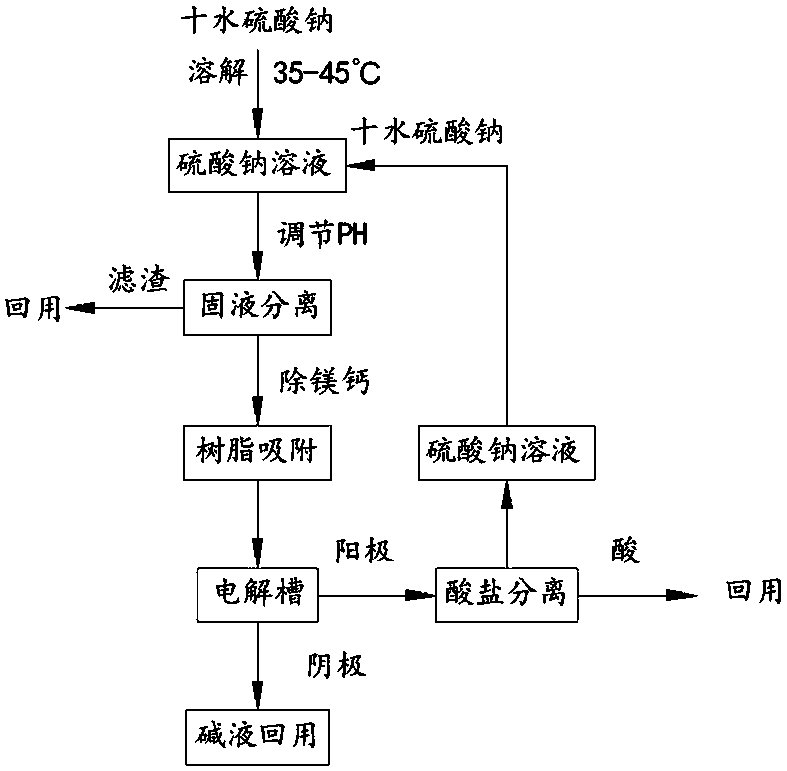

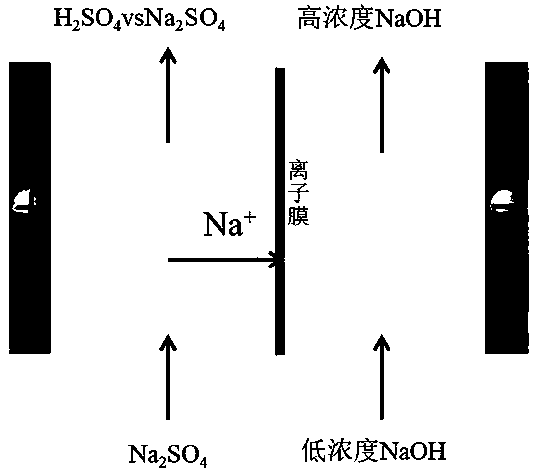

[0037] Such as figure 1 and 3 As shown, a chemical fiber production enterprise obtains Glauber’s salt by freezing crystallization method, uses the precipitated sodium sulfate decahydrate as feed material, and prepares a sodium sulfate solution with a mass concentration of 300-350g / L under the condition of 42-45°C, which contains zinc ion 287mg / L; use sodium hydroxide to adjust the pH of the above prepared sodium sulfate solution to 8.5-9.0, use plate and frame solid-liquid separation to recover zinc hydroxide from the filter residue, and the recovered zinc hydroxide is directly used in the coagulation bath section; Sodium carbonate is added to the post-zinc solution to remove calcium and magnesium chemically. After the treatment, the solution is precisely filtered by a ceramic filter and then enters the D403 cation exchange system for deep adsorption treatment of calcium, magnesium and trace zinc, so that the mass concentration of calcium ions in the effluent is less than 0.1m...

Embodiment 2

[0039] Such as figure 1 and 3 As shown, a certain Fiber Co., Ltd. produces about 100,000 tons of Glauber's salt annually, and uses the precipitated sodium sulfate decahydrate as the feed material to prepare a sodium sulfate solution with a mass concentration of 280-300g / L under the condition of 35-40°C. It contains 152mg / L of zinc ions; use sodium hydroxide to adjust the pH of the above-prepared sodium sulfate solution to 8.5-9.0, use PP filter elements to recover zinc hydroxide from the filter residue, and the recovered zinc hydroxide is directly used in the coagulation bath section; Sodium carbonate is added to the solution after zinc removal to chemically remove calcium and magnesium. After the treatment, the solution is precisely filtered by a ceramic filter and then enters the D113 cation exchange system for deep adsorption treatment of calcium, magnesium and trace zinc to achieve a concentration of calcium ions in the effluent of less than 0.1 mg / L, the mass concentrati...

Embodiment 3

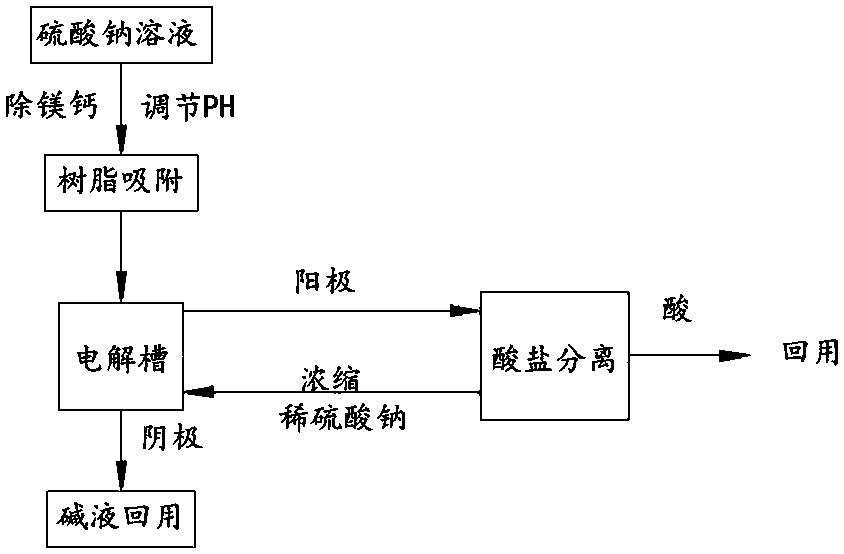

[0041] Such as figure 2 and 3 As shown, a Carlin-type refractory gold ore in a certain mine is pretreated with sodium hydroxide to desulfurize and extract gold. The demand for acid and alkali is large. After the raw ore is pre-oxidized and desulfurized by sodium hydroxide, the solution is mainly sodium sulfate solution with a mass concentration of 150-200g / L; sodium carbonate and sodium hydroxide are used to adjust the pH of the sodium sulfate solution prepared above to 8.5-9.0, and ceramic After precision filtration by the filter, it enters the D403 cation exchange system for deep adsorption treatment of calcium, magnesium and other metals, so that the mass concentration of calcium ions in the effluent is less than 0.1mg / L, and the mass concentration of magnesium ions is less than 0.1mg / L; the liquid after deep adsorption treatment After filtering with a ceramic filter, ensure that the suspended matter SS of the filtrate is less than 10mg / L, and the SiO 2 Content less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com