Method for separating and reclaiming vanadium and chromium from solution containing vanadium and chromium

A technology of aqueous solution and mixed solution, applied in the direction of improving process efficiency, etc., can solve the problems of difficult vanadium resource recovery, complex process route, difficult separation, etc., and achieve the effect of simple resource, process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

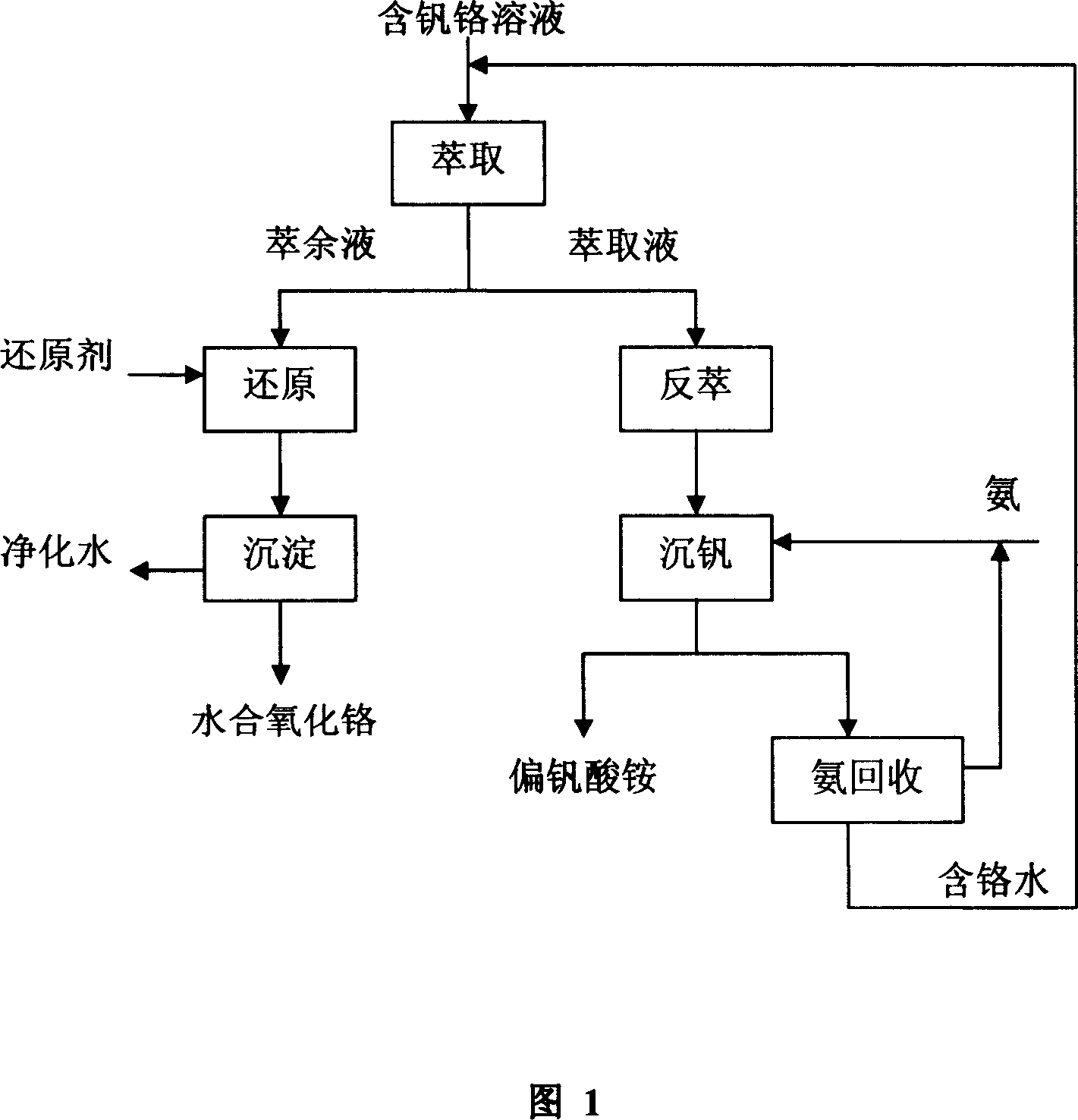

Image

Examples

Embodiment 1

[0026] Adjust 1 liter of solution containing pentavalent vanadium (1000mg / L) and hexavalent chromium (500mg / L) to 5.6 with hydrochloric acid or sodium hydroxide, and then mix it with 1# amine extractant (containing 10% LK-N21, 5% 7201 and 85% kerosene) were mixed at a ratio of 1:1, stirred at 40°C for 2 minutes, and left to stand until the oil and water were completely separated; the raffinate (water phase) was adjusted to pH 3 by adding hydrochloric acid, and then added to the solution The theoretical amount of anhydrous sodium sulfite is 1.02 times. After reacting for 30 minutes, adjust the pH value to 7 with NaOH, and filter to obtain hydrated chromium oxide; stir the vanadium-containing organic phase with 40ml 1.0M NaOH at 60°C for 5 minutes, and let it stand until the oil and water are completely separated. Take the water phase and add 5 times the theoretical amount of ammonium chloride to react at 80°C for 20min, filter to obtain ammonium metavanadate after precipitation,...

Embodiment 2

[0030] 10 liters of solutions containing pentavalent vanadium (500mg / L) and hexavalent chromium (2000mg / L) were adjusted to pH 6.0 with hydrochloric acid or sodium hydroxide, and then mixed with 2# amine extractant (containing 15% 1923, 2% 7201 and 83% toluene) were mixed in a ratio of 2:1, stirred at 20°C for 15 minutes, and left to stand until the oil and water were completely separated; adding hydrochloric acid to the raffinate to adjust the pH to 3, and then adding 1.06 times the theoretical amount of formaldehyde to the solution , react at 200°C for 180min, then cool down to room temperature and adjust the pH value to 7.5 with NaOH, and filter to obtain hydrated chromium oxide; stir the vanadium-containing organic phase with 200ml 1.5M NaOH at 40°C for 20min, and let it stand until the oil and water are completely separated. Get the water phase and add 5.5 times the theoretical amount of ammonium chloride and react at 35°C for 50 minutes, filter to obtain ammonium metavana...

Embodiment 3

[0034]A solution containing pentavalent vanadium (9000mg / L) and hexavalent chromium (4000mg / L) was adjusted to pH 4.4 with hydrochloric acid or sodium hydroxide, and then mixed with 3# amine extractant (containing 25% JMT and 75% tetrachloride carbon dioxide) at a ratio of 1:1, five-stage countercurrent continuous extraction was carried out at 25°C. In each stage, the mixing time is 7 minutes, and the standing time is 20 minutes; the raffinate is added with hydrochloric acid to adjust the pH value to 2.5, and then anhydrous sodium sulfite 1.05 times the theoretical amount is added to the solution, and the pH value is adjusted to 8 with NaOH after reacting for 30 minutes. , and filtered to obtain hydrated chromium oxide; vanadium-containing organic phase and 2.0M Na 2 CO 3 According to the ratio of 4:1, three stages of countercurrent stripping were carried out at 45°C, the stirring time of each stage was 20 minutes, and the mixture was allowed to stand for 30 minutes. Get wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com