Oil-containing sludge treating method

A treatment method and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems affecting the volatile and ash index of coke, complex evaporation system, large power consumption, etc., achieve remarkable treatment effect and simple process , low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

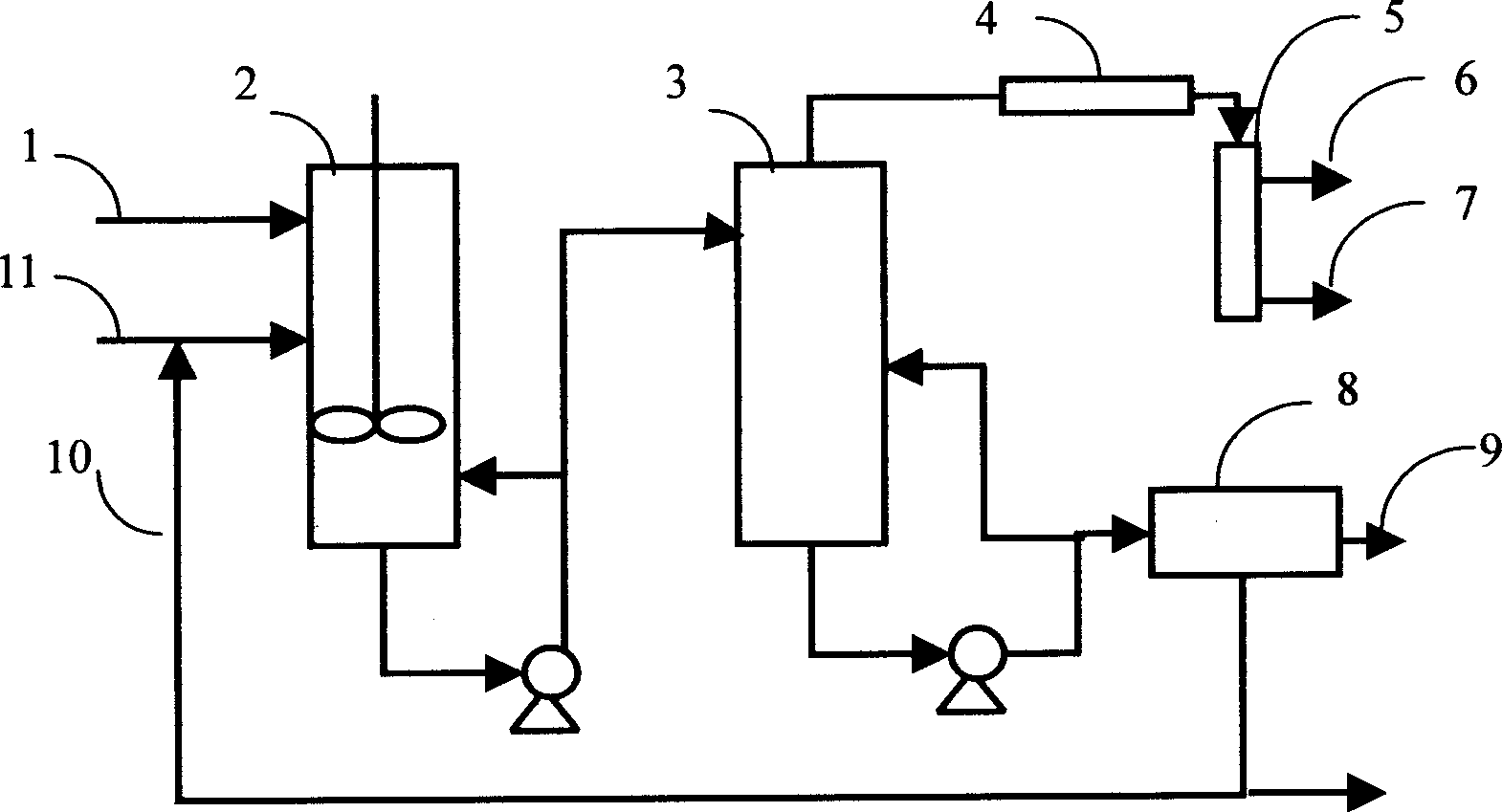

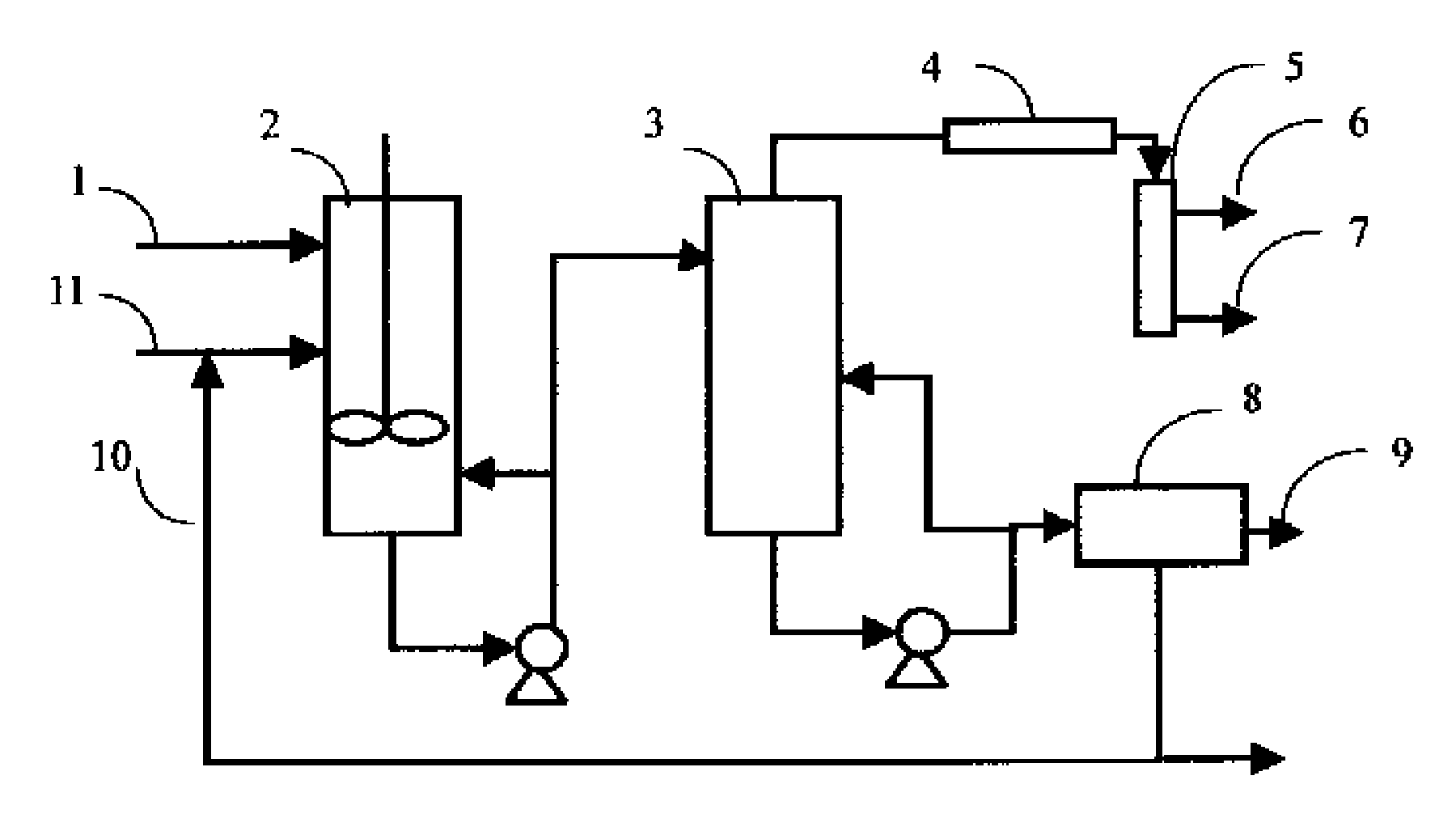

Method used

Image

Examples

Embodiment 1

[0015] Take 10L of grease trap bottom sludge (81.2% water content, 5.5% solid content, 13.3% oil content) after mechanical dehydration in a refinery, and 30L kerosene at normal pressure, send it into the sludge mixing tank and heat it to 75 °C, use a pump to send the mixed material into the thermal extraction tower for dehydration for continuous operation. The extraction-dehydration operating conditions are: normal pressure, 105 °C, and the residence time is 40 minutes. The COD was 140mg / l and the oil in water was 17mg / l by removing water and sending sample analysis. The calorific value of the separated solid is 8120cal / g, which is higher than that of general standard coal, and neither the solid nor the oil phase contains water.

Embodiment 2

[0017] After centrifugal dehydration, the scum of a refinery contains 10.3% oil and 84.3% water. Take 4L of scum and 10L of Saudi regular first-line distillate oil as solvent oil, heat and mix in the mixing tank, and send it to extraction when the temperature reaches 100°C / Dehydration tower for continuous extraction / dehydration treatment, dehydration extraction at normal pressure 110°C, residence time is 25 minutes, water and some light component oil are condensed from the top of the tower through the condenser and enter the oil-water separation tank, water samples are taken from the bottom The analytical oil is 24mg / l, and the COD is 310mg / l, which meets the biochemical influent requirements of the sewage field and can be directly sent to the biological oxidation facility for further treatment. The organic components and solids in solvent oil and sludge enter the solid-liquid separator. Due to the removal of water and the extraction of the oil phase, the solids are easily sep...

Embodiment 3

[0019] The mixture of bottom sludge, scum and remaining activated sludge in a grease trap in a refinery contains 13.3% oil and 80.3% water after plate and frame pressure filtration. Take 4L of scum and 25L of coking wax oil, and heat and mix them in a mixing tank , when the temperature reaches 100°C, it is sent to the extraction / dehydration tower for continuous processing, dehydration extraction is carried out at 125°C under normal pressure, the residence time is 15 minutes, water and part of the light component oil are condensed from the top of the tower into the oil water In the separation tank, water samples were taken from the bottom to analyze that the oil was 19mg / l and the COD was 221mg / l, which met the biochemical water inflow requirements of the sewage field and could be directly sent to the biological oxidation facility for further treatment. The organic components and solids in solvent oil and sludge enter the solid-liquid separator. Due to the removal of water and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com