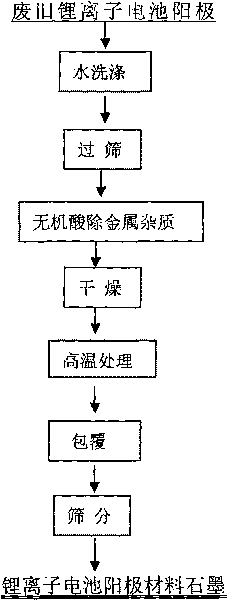

Method for recovering and restoring anode material graphite of waste lithium ion battery

A technology for lithium ion batteries and anode materials, which is applied in the field of recycling and repairing anode material graphite of waste lithium ion batteries, can solve problems such as the blank of anode graphite recycling, and achieve the effects of high added value of products, reduced energy consumption and short process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

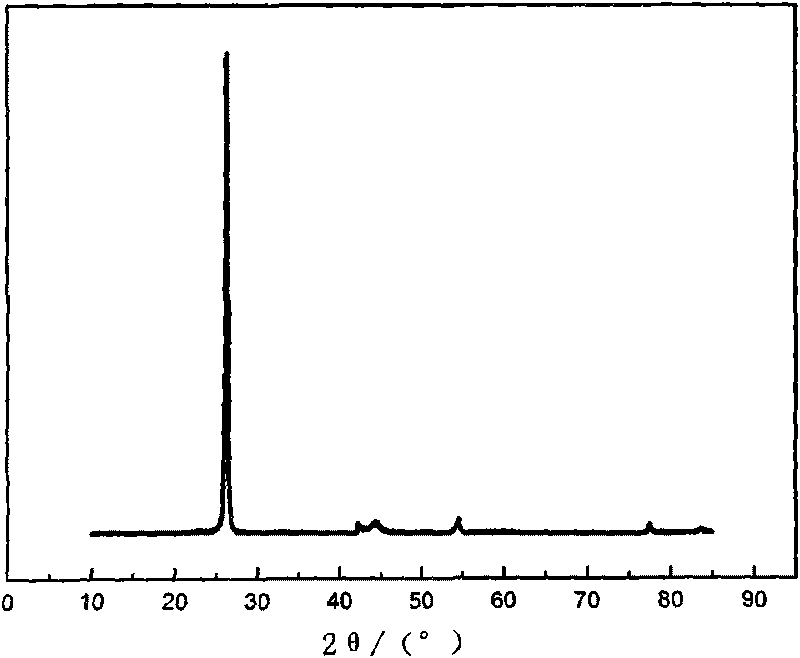

Embodiment 1

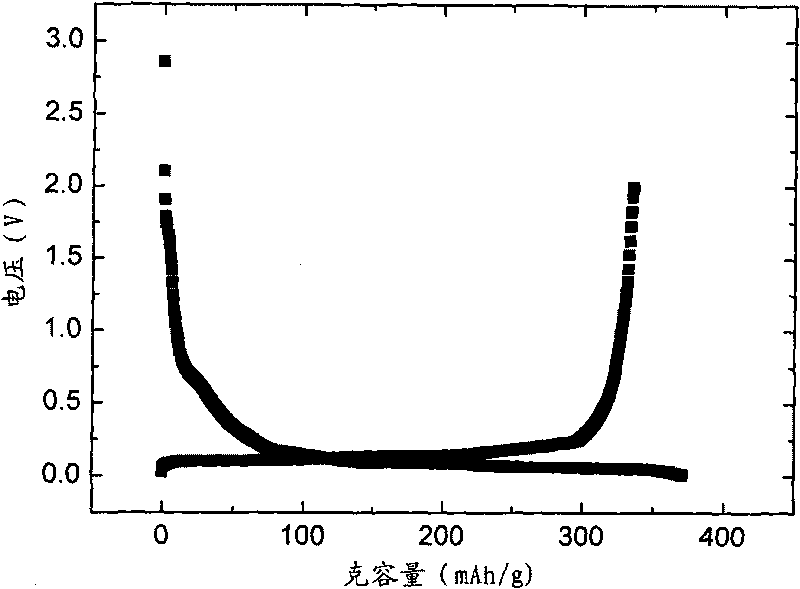

[0036] Soak 10 pieces of 18650-type lithium-ion battery negative electrodes in warm water at 80°C and stir at a stirring speed of 200r / min, washing time of 4h, filter, dry, and pass through a 100-mesh standard sieve to obtain 140g of graphite powder. Get 140 grams of graphite powder and soak in the mixed solution of 200ml, 0.4mol / L sodium chlorate and 2mol / L hydrochloric acid, and constantly stir, stirring speed is 250r / min, and the reaction times is 2.5h, removes the metal impurity in graphite, then Filter and dry at 90°C to constant weight. Take 120 grams of dry graphite from which metal impurities have been removed, place it in a ceramic crucible, put it into a muffle furnace, and in an air atmosphere, raise the temperature to 500°C at a rate of 10°C / min and keep it warm for 2 hours to obtain 113.1g of pure graphite, namely graphite Sample, high temperature weight loss rate is 5.75%.

[0037]100 g of the obtained graphite sample was immersed in 200 ml of a surface modifica...

example 2

[0040] Soak 10 pieces of 18650-type lithium-ion battery negative electrodes in warm water at 70°C and stir at a stirring speed of 200r / min for 4 hours, filter, dry, and pass through a 100-mesh standard sieve to obtain 140 grams of graphite powder. Get 140 grams of graphite powder and soak in the mixed solution of 200ml, 0.4mol / L hydrogen peroxide and 1mol / L sulfuric acid, and keep stirring, the stirring speed is 250r / min, the reaction time is 2.5h, remove the metal impurities in the graphite, then filter, Dry at 90°C to constant weight. Take 120 grams of dry graphite from which metal impurities have been removed, place it in a ceramic crucible, put it into a muffle furnace, and in an air atmosphere, raise the temperature to 550°C at a rate of 10°C / min and keep it warm for 2 hours to obtain 111.0g of pure graphite, namely graphite The high temperature weight loss rate of the sample is 7.50%.

[0041] 100 g of the obtained graphite sample was immersed in 200 ml of a surface mod...

example 3

[0043] Soak 10 pieces of 18650-type lithium-ion battery negative electrodes in warm water at 75°C and stir at a stirring speed of 200r / min, washing time of 4h, filter, dry, and pass through a 100-mesh standard sieve to obtain 140g of graphite powder. Get 140 grams of graphite powder and soak in the mixed solution of 200ml, 0.4mol / L hydrogen peroxide and 2mol / L hydrochloric acid, and keep stirring, the stirring speed is 250r / min, the reaction time is 2.5h, remove the metal impurities in the graphite, then filter, Dry at 90°C to constant weight. Take 120 grams of dry graphite from which metal impurities have been removed, place it in a ceramic crucible, put it into a muffle furnace, and in an air atmosphere, raise the temperature to 580°C at a rate of 10°C / min, and keep it warm for 2 hours to obtain 107.2g of pure graphite, namely graphite The high temperature weight loss rate of the sample is 10.66%.

[0044] 100 g of the obtained graphite sample was immersed in 200 ml of a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com