Method and device for uniformly cladding metallic silver on surface of carbon nano tube

A carbon nanotube, surface uniform technology, applied in transportation and packaging, metal processing equipment, metal material coating technology, etc., can solve the weakening effect of vibration, affecting the binding force of silver and carbon nanotubes, the growth of metal particles, etc. problems, to achieve the effects of avoiding solution self-decomposition, easy continuous preparation, and simple experimental procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

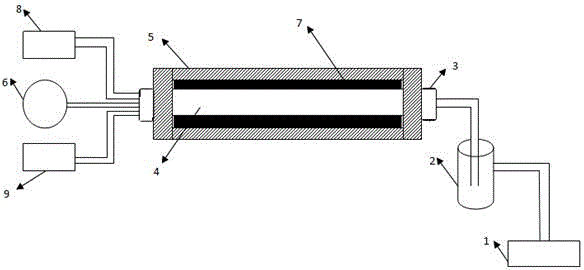

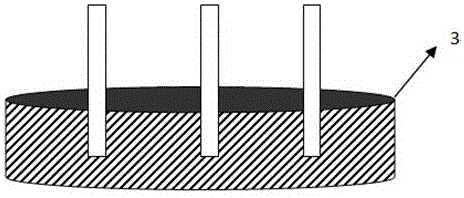

Method used

Image

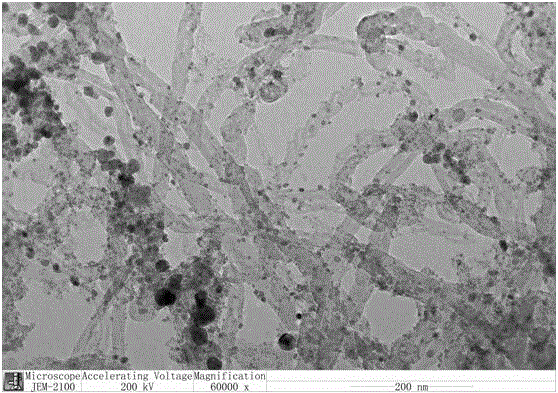

Examples

Embodiment 1

[0040] The method for uniformly coating metallic silver on the surface of carbon nanotubes of the present invention specifically comprises the following steps:

[0041] Step 1) Pretreatment of carbon nanotubes

[0042] (1) Acidification treatment of carbon nanotubes: Add carbon nanotubes to mixed acid, which is made by mixing concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% at a volume ratio of 3:1. The addition of carbon nanotubes Add 1.5g of carbon nanotubes per 100mL of mixed acid, heat and reflux in a water bath at 70°C for 3 hours, then dilute with deionized water and wash until neutral, separate the obtained carbon nanotubes, and obtain acidified After the carbon nanotubes;

[0043](2) Sensitization treatment: add the acidified carbon nanotubes into the sensitization solution at 1:100g / mL and ultrasonically treat them for 30min, then dilute with deionized water and wash until neutral, then separate the obtai...

Embodiment 2

[0055] The method for uniformly coating metallic silver on the surface of carbon nanotubes of the present invention specifically comprises the following steps:

[0056] Step 1) Pretreatment of carbon nanotubes

[0057] (1) Acidification treatment of carbon nanotubes: Add carbon nanotubes to mixed acid, which is made by mixing concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% at a volume ratio of 3:1. The addition of carbon nanotubes Add 2g of carbon nanotubes per 100mL of mixed acid, heat and reflux in a water bath at 70°C for 3 hours, then dilute with deionized water and wash until neutral, separate the obtained carbon nanotubes, dry and obtain acidified carbon nanotubes;

[0058] (2) Sensitization treatment: add the acidified carbon nanotubes into the sensitization solution at 2:100g / mL and ultrasonically treat them for 30 minutes, then dilute with deionized water and wash until neutral, then separate the obtaine...

Embodiment 3

[0069] The method for uniformly coating metallic silver on the surface of carbon nanotubes of the present invention specifically comprises the following steps:

[0070] Step 1) Pretreatment of carbon nanotubes

[0071] (1) Acidification treatment of carbon nanotubes: Add carbon nanotubes to mixed acid, which is made by mixing concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% at a volume ratio of 3:1. The addition of carbon nanotubes Add 3g of carbon nanotubes per 100mL of mixed acid, heat and reflux in a water bath at 70°C for 3 hours, then dilute with deionized water and wash until neutral, separate the obtained carbon nanotubes, dry and obtain acidified carbon nanotubes;

[0072] (2) Sensitization treatment: add the acidified carbon nanotubes into the sensitization solution according to 1.5:100g / mL and ultrasonically treat them for 30min, then dilute with deionized water and wash until neutral, and separate the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com