Thin-wall pipe material heat conductivity coefficient calculating method

A technology for calculating thermal conductivity and thermal conductivity, which is applied in the field of calculating thermal conductivity of thin-walled circular tube materials, and can solve the problems of thermal conductivity and measurement methods for thin-walled circular tube materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

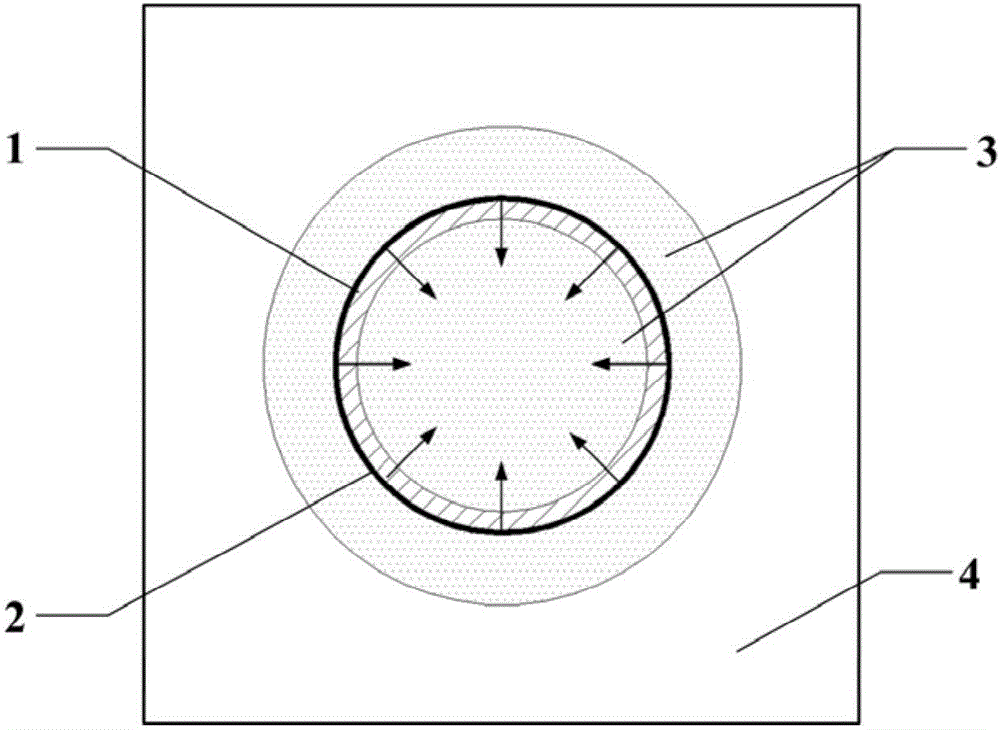

[0026] system structure

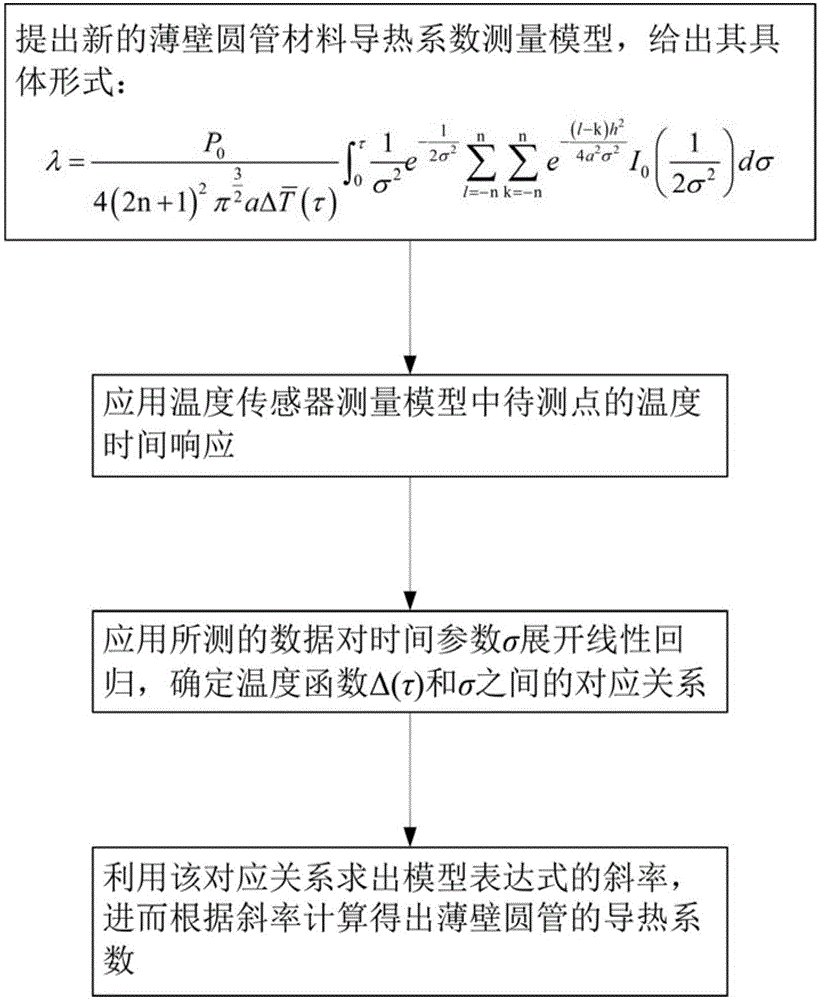

[0027] The invention discloses a method for calculating the thermal conductivity of a thin-walled circular tube material. The method is based on a transient heat conduction calculation model, uses a plurality of equidistant heating rings to heat the circular tube to be tested, and simultaneously measures the temperature change of the heated portion on the surface of the circular tube to be tested. , to obtain the temperature-time response data of multiple equidistant rings on the surface of the ring to be tested, and then calculate the thermal conductivity of the material. The calculation process refers to figure 1 .

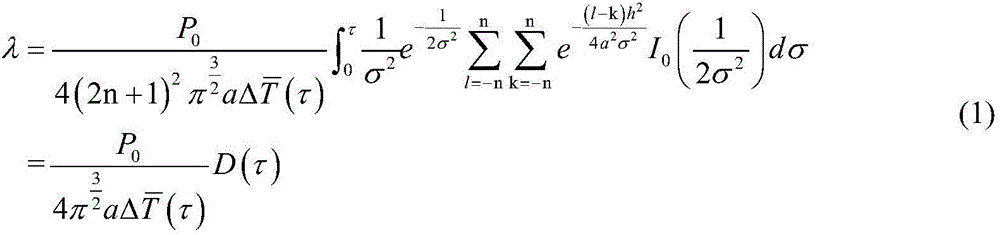

[0028] The object to be studied by the present invention is the thermal conductivity of solid materials. First, according to Fourier's law, the three-dimensional temperature change inside the tube to be measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com