Ultrasonic atomization assisted electrospinning technique

An electrospinning technology and ultrasonic atomization technology, applied in the field of ultrasonic atomization-assisted electrospinning technology, can solve problems such as easy clogging of spinning nozzles, low proportion of additives, uneven mixing of nanoparticles/fiber membranes, etc. Achieve improved physical and chemical properties, excellent water resistance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

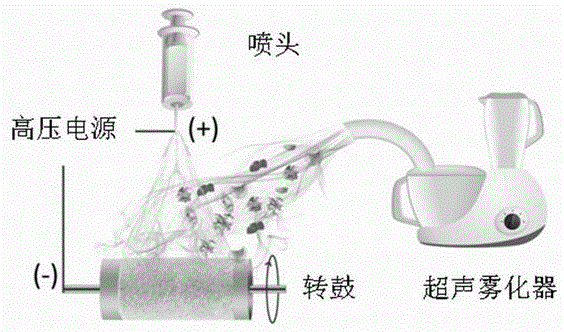

[0016] Dissolve polyacrylonitrile (Mw=150,000) in dimethylacetamide to prepare an electrospinning solution with a concentration of 10wt.%. Take 20mL of the polyacrylonitrile solution and place them in two 10mL syringes respectively. Take 200mL of the concentration as 2 mg / mL graphene oxide solution in an ultrasonic nebulizer. Graphene oxide was obtained by ultrasonic atomization-assisted electrospinning under the conditions that the inner diameter of the needle is 0.2mm, the voltage between the needle and the receiver is 22kV, the distance is 13cm, the propulsion speed is 0.8L / h, and the ultrasonic atomization power is 50W. Composites with polyacrylonitrile fibers, operating modes such as figure 1 As shown, the obtained graphene oxide and polyacrylonitrile composite film is as follows figure 2 Shown, wherein the addition ratio of graphene oxide is 10%.

Embodiment 2

[0018] Dissolve polyvinylpyrrolidone in dimethylformamide solvent to prepare an electrospinning solution with a mass fraction of 10wt.%, then weigh a certain amount of carbon nanotubes and put them into dimethylacetamide with a mass fraction of 2wt.%, and Thoroughly stir and ultrasonically disperse to obtain 400 mL of uniformly dispersed carbon nanotube dispersion. Electrospinning process parameters: the volume of the syringe is 10mL, the inner diameter of the needle is 0.2mm, the voltage between the needle and the receiver is 22kV, the distance is 15cm, and the advancing speed of the electrospinning liquid is 0.8L / h. At the same time, start the ultrasonic atomization device to atomize the carbon nanotubes into the electrospun membrane. At the same time, according to the needs, realize the uniform mixing of the carbon nanotubes and the polyvinylpyrrolidone film, and the addition ratio of the carbon nanotubes is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com