Atomization penetrating flaw detection device

A technology of penetrating flaw detection and penetrating liquid, which is applied to measuring devices, material analysis by optical means, instruments, etc., can solve the problems of difficult discharge of penetrating liquid, tuition and miscellaneous fees, penetrating liquid, load, etc., and achieves easy automation control and reduces workload. , to ensure the effect of the penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

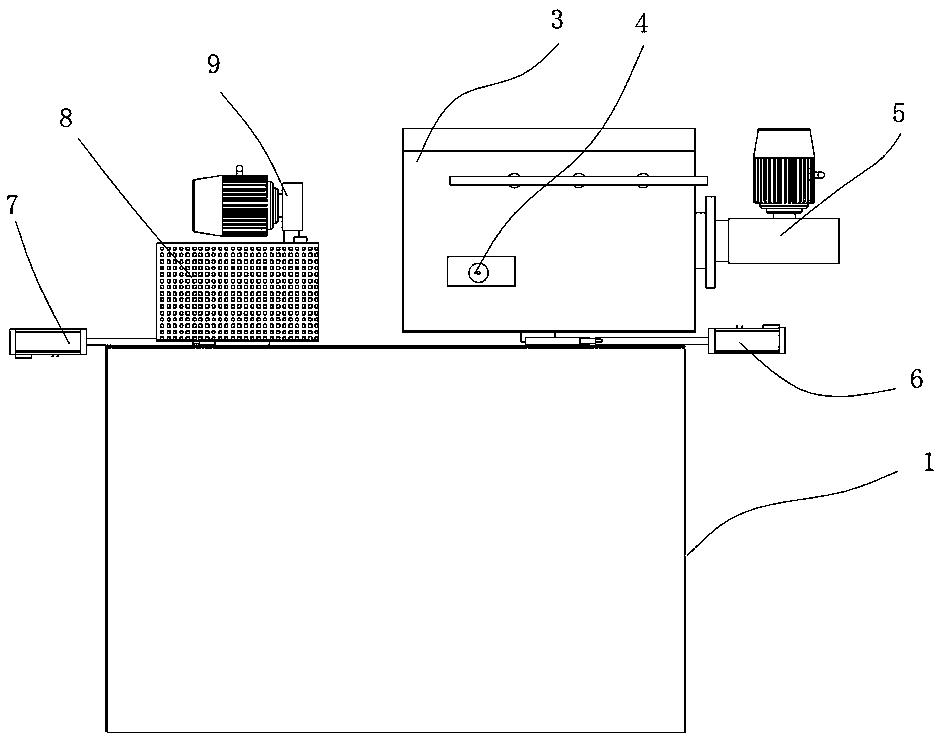

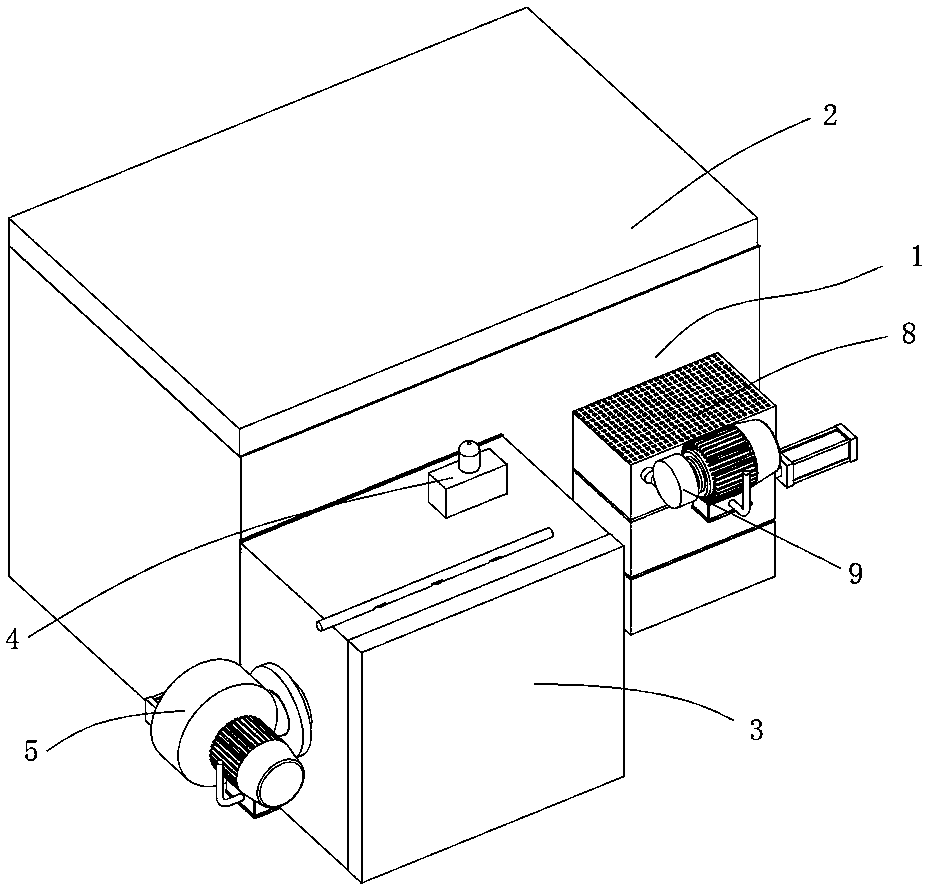

[0024] Example: see figure 1 and figure 2 As shown, an atomized penetrant flaw detection device includes a permeation tank, a permeate supply device connected to the permeation tank, and an exhaust gas exhaust device. The permeation tank has a tank body and an openable and closable cover. A sealing ring is provided. When the cover body is closed, the cover body, the sealing ring and the tank form a closed inner cavity. The setting of the sealing ring can prevent the atomized penetrant from leaking out.

[0025] The permeate supply device includes a spray box, a spray valve, a two-way fan, and a spray concentration meter. The spray box is provided with a permeate atomizing nozzle for forming a spray of the permeate; the spray box is connected to the permeation tank through the spray valve, and the spray valve control on-off;

[0026] The waste gas exhaust device includes an exhaust valve, a waste gas filter box and an exhaust fan. The exhaust gas filter box is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com