Ultrasonic atomization electronic cigarette

A technology of ultrasonic atomizing tablets and electronic cigarettes, which is applied in the fields of tobacco, smoker’s supplies, applications, etc. It can solve the problems of uneven heating affecting the user experience, the increase of microorganisms in electronic cigarette liquid, and the harm of harmful substances to health, so as to increase the use of simulation Effect, elimination of microbial contamination, small and uniform effect of aerosol droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

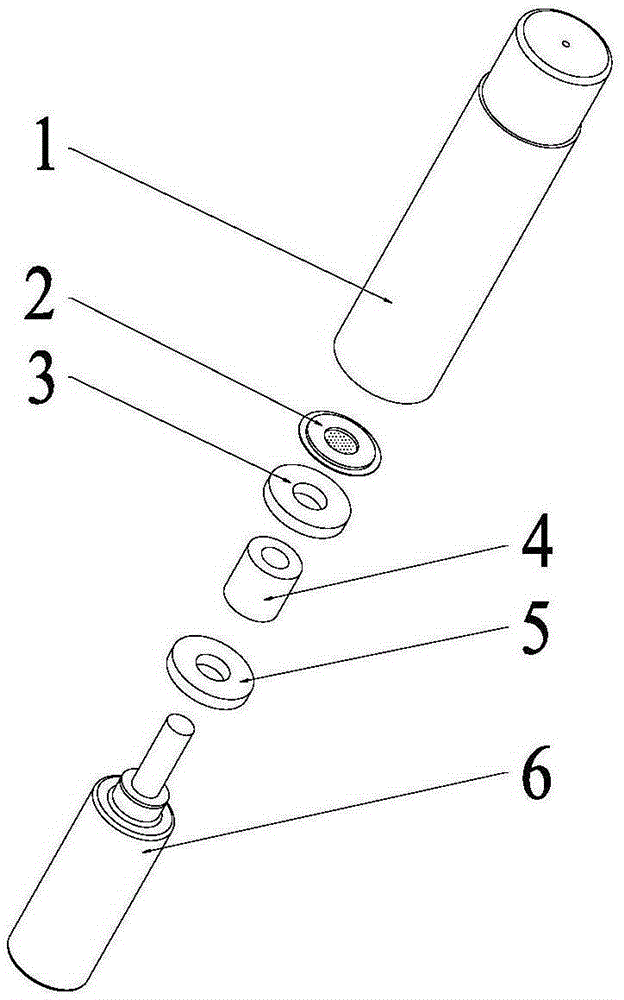

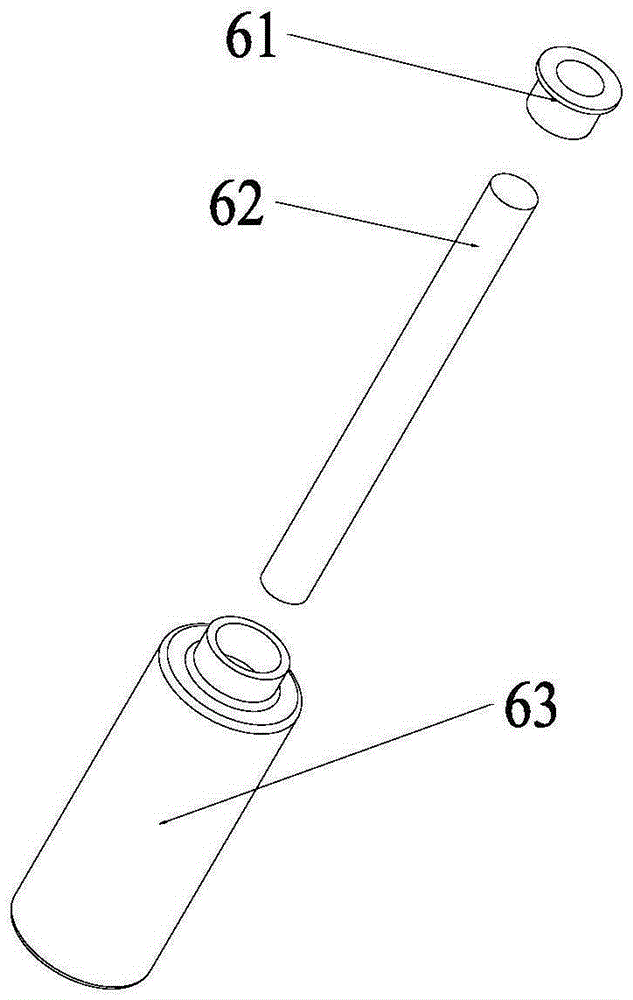

[0015] Such as figure 1 As shown, the atomization heating part of the ultrasonic atomizing electronic cigarette of the present invention includes an upper shell 1, an ultrasonic atomizing sheet 2, an upper heat insulating gasket 3, a ceramic heating tube 4, a lower heat insulating gasket 5, and a replaceable cigarette Core 6. The upper heat insulating gasket 3 fixes the ultrasonic atomizing sheet 2 inside the upper casing 1 . The lower heat insulating gasket 5 fixes the ceramic heating tube 4 between the upper heat insulating gasket 3 and the lower heat insulating pad 5 . When in use, the replaceable smoke core 6 is fixed inside the upper shell 1, and the liquid guide rod 62 of the replaceable smoke core 6 passes through the holes in the upper heat insulating gasket 3, the ceramic heating tube 4, and the lower heat insulating gasket 5 to meet the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com