Ultrasonic atomization and vaporization seawater desalination desalting device and method

A desalination device and ultrasonic technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc., can solve the problems of high cost, cumbersome auxiliary equipment, rising salt content, etc., and achieve low input and treatment costs. The effect of low operation and maintenance cost and low production water cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

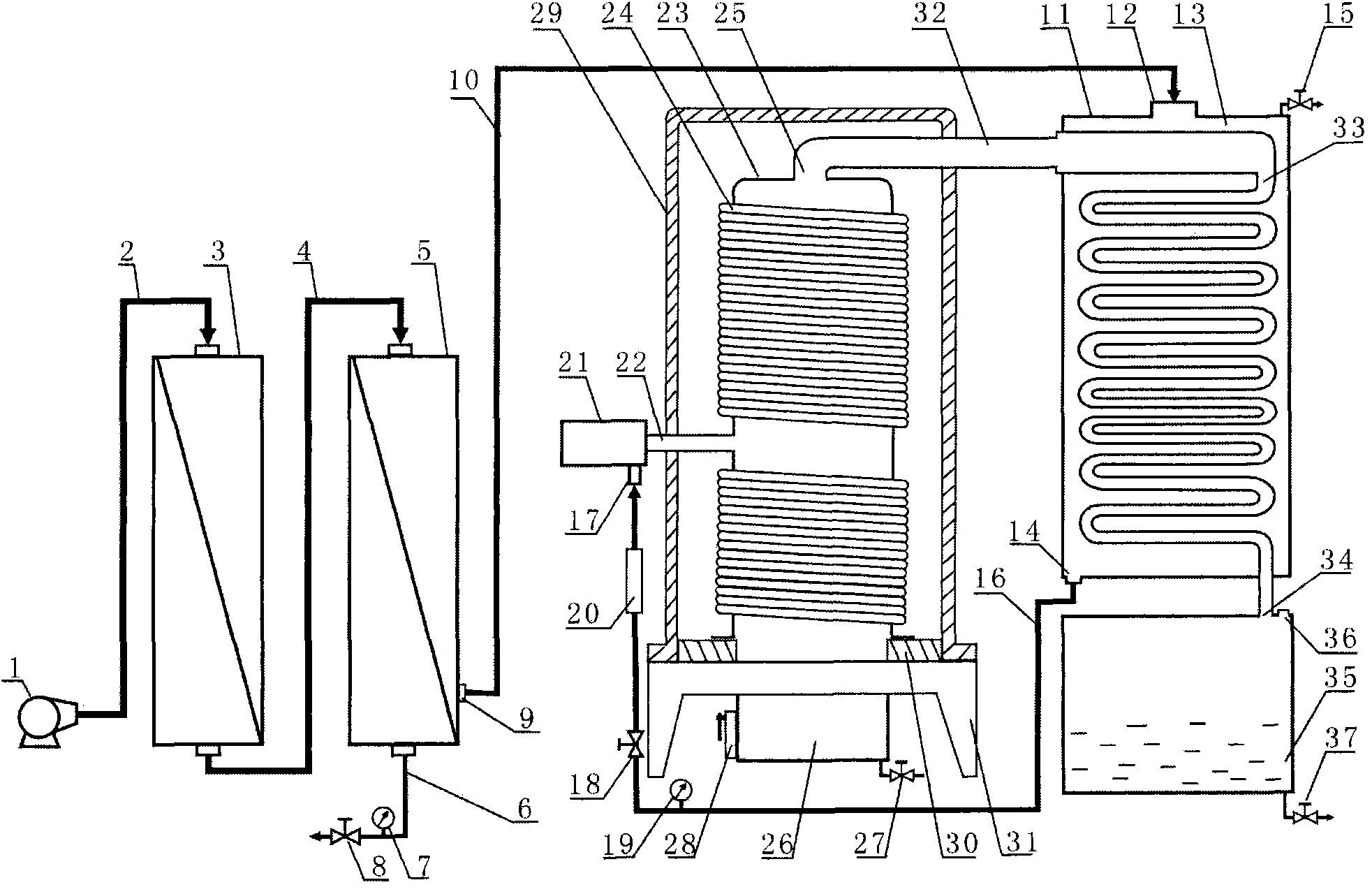

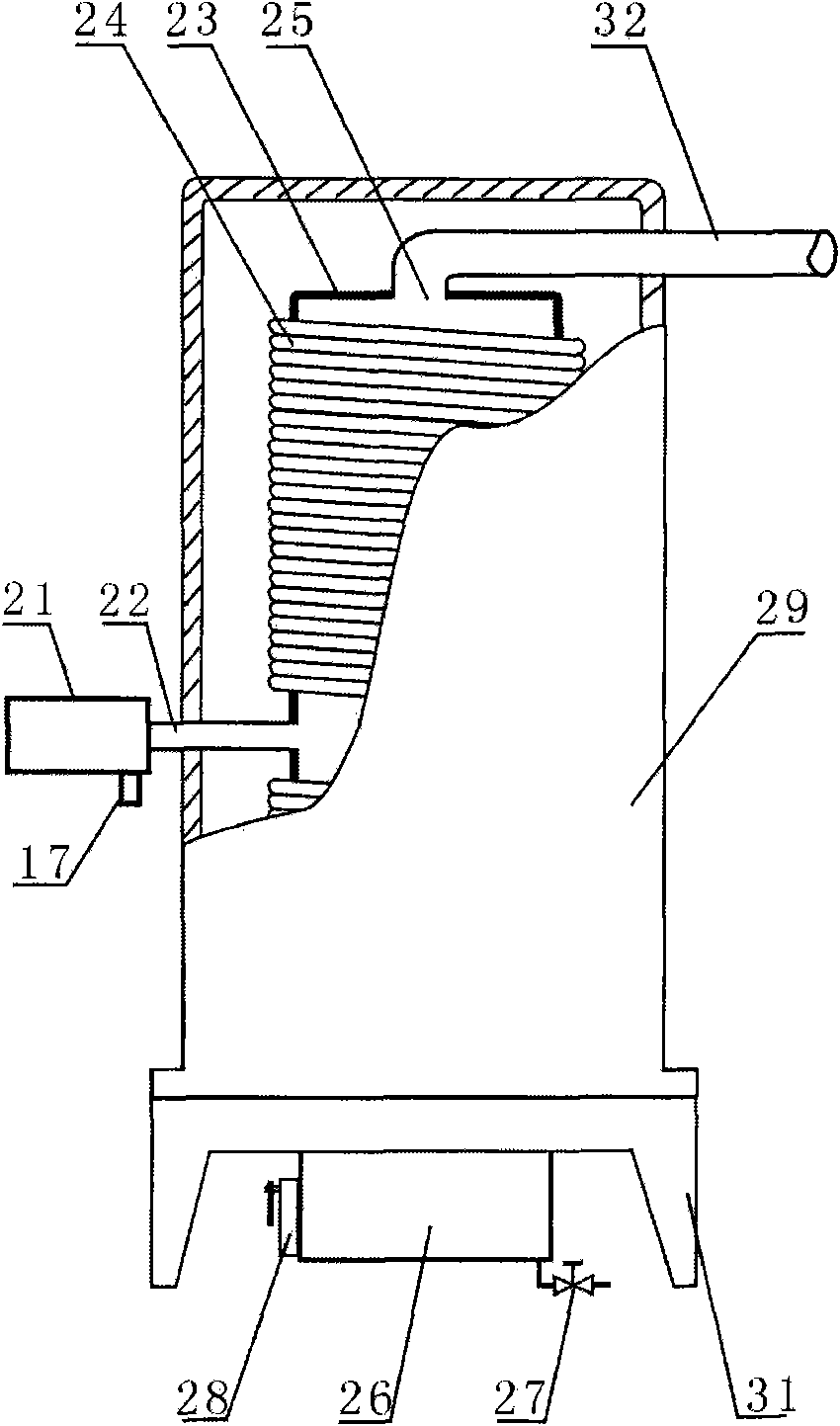

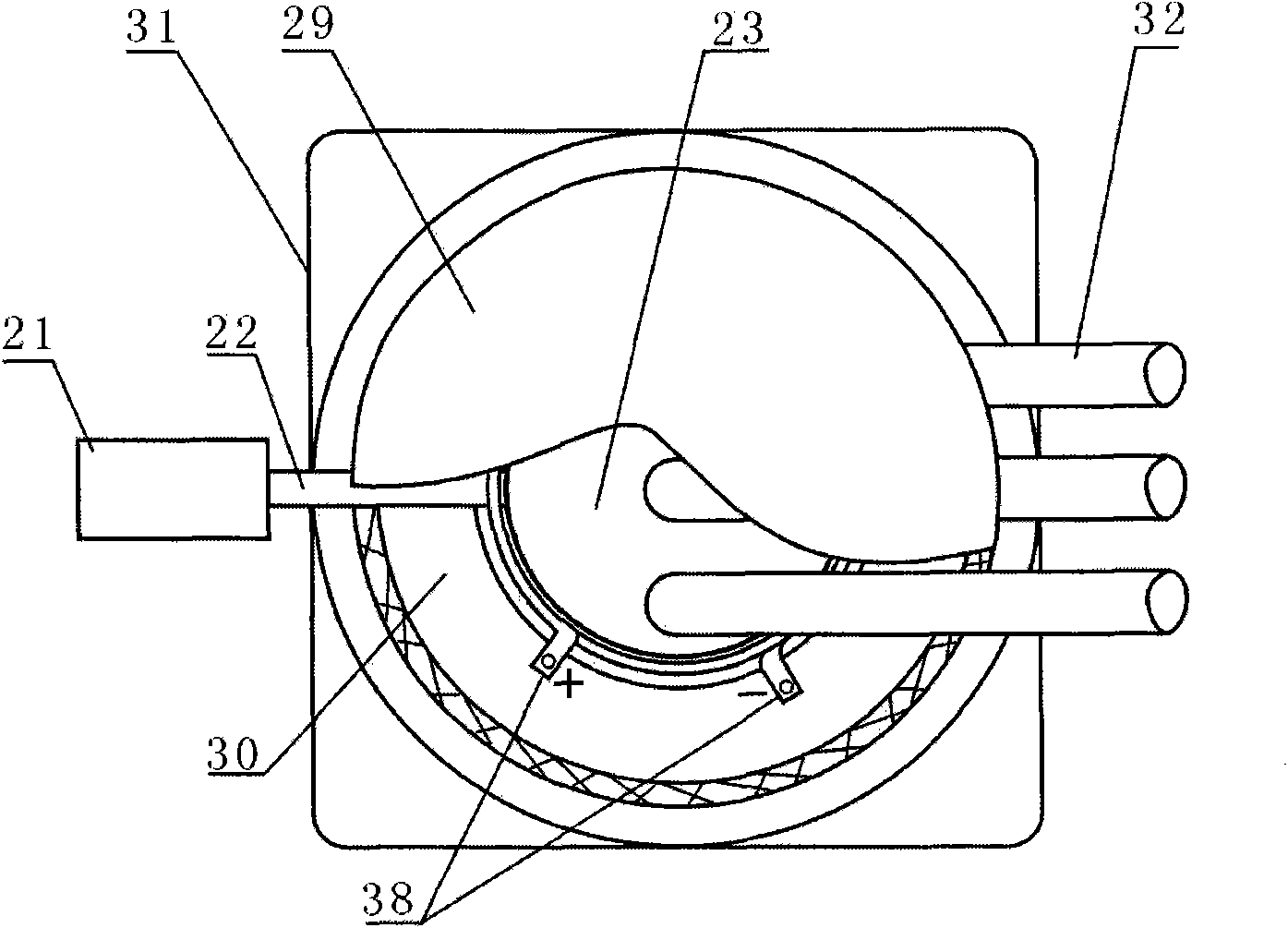

[0085] Such as figure 1 As shown, the ultrasonic atomization vaporization seawater desalination and desalination device of the present invention includes pretreatment equipment, ultrasonic resonance atomizer 21, electromagnetic induction heating vaporization furnace 23, heat exchange condenser 11, and desalination water tank 35;

[0086] The pretreatment equipment includes a sea water feed pump 1, a precision filter 3, and a hollow fiber ultrafiltration membrane separation processor 5. Membrane separation processor 5; hollow fiber ultrafiltration membrane separation processor 5 is provided with concentrated water discharge port and pipeline 6, water outlet 9, concentrated water discharge pipeline 6 is provided with concentrated water pressure regulating valve 8, concentrated water pressure gauge 7 , the concentrated water pressure regulating valve 8 is used to adjust the water pressure of the concentrated water discharge pipeline 6 to keep the water pressure in the range of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com