Preparation method for ultrasonic atomization spraying film

A technology of ultrasonic atomization and spraying liquid, applied in the directions of spraying device, spraying device, liquid spraying device, etc., can solve the problems of application scope or application object limitation, etc., and achieve the effect of wide application range, high appearance quality and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

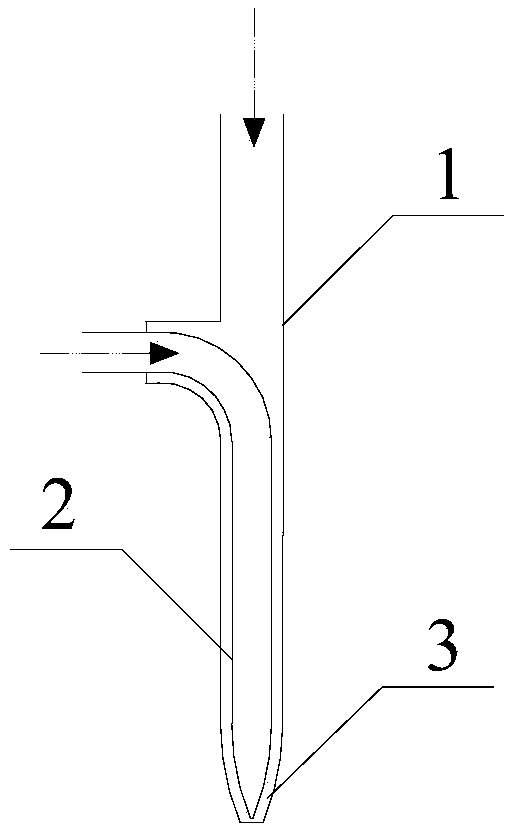

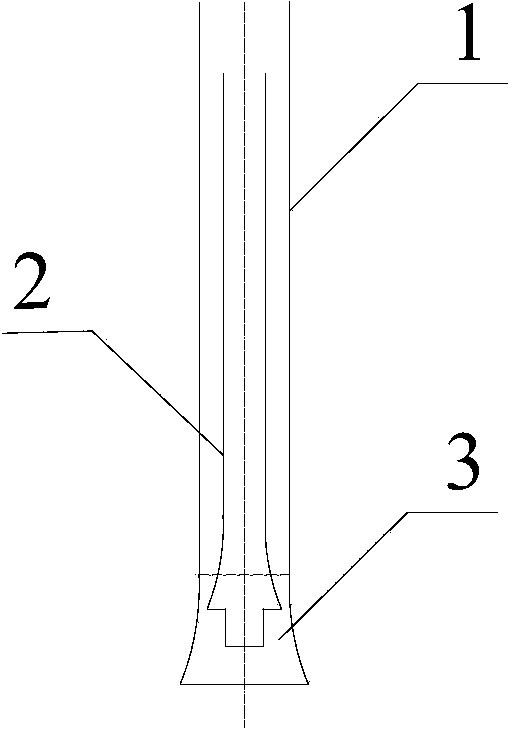

specific Embodiment 1

[0047] Assemble the ultrasonic spraying equipment, put a nano-titanium dioxide self-cleaning sol used on the glass surface in the ultrasonic atomization chamber, immerse the sol in the ultrasonic atomization generator, and maintain a certain liquid level. Prepare the glass substrate, adjust the ultrasonic frequency of the ultrasonic atomization generator to 2.0MHz, turn on the power supply, and the ultrasonic atomization generator starts to work, and instantly atomizes the sol into a very fine liquid mist with a particle size of 10nm to 30nm, and passes through The mist conduit reaches the double-layer nozzle, and under the action of the air flow, the liquid mist is taken out of the spray port to form a uniform liquid mist stream, keeping the glass substrate at a position of 5-8 cm directly below the spray port, and spraying with 1.5 The speed of cm / s moves forward flatly, and the glass substrate deposits a layer of nanometer self-cleaning coating with uniform thickness and tra...

specific Embodiment 2

[0048] For extremely small workpieces, the surface needs to be sprayed with a layer of paint, as follows: first assemble the ultrasonic spraying equipment, and install nozzles of the same area on the equipment according to the area to be coated on the surface of the workpiece (specifically, double-layer nozzles) Inner mouth area) spray head, put the liquid paint in the ultrasonic atomization chamber, the paint is immersed in the ultrasonic atomization generator, and maintain a certain liquid level. Adjust the ultrasonic frequency of the ultrasonic atomizing generator to 2.0MHz, start the power supply, and the ultrasonic atomizing generator starts to work, and instantly atomizes the paint into a very fine liquid mist with a particle size of 10nm to 30nm, and reaches the double layer through the mist outlet tube Nozzle, under the action of nitrogen flow, the liquid mist is taken out of the spray port, forming a uniform liquid mist stream, keeping the workpiece at a position of 5-...

specific Embodiment 3

[0049] For the coating on the surface of some immovable workpieces, the method adopted is as follows: first, according to the area of the workpiece surface to be coated, the equipment is equipped with nozzles with the same area of nozzles (specifically, the inner nozzle of the double-layer nozzle Area), the double-layer spray head is a hand-held spray head, assemble the ultrasonic spraying equipment, install the double-layer spray head on the equipment, put the liquid paint in the ultrasonic atomization chamber, and immerse the paint in the ultrasonic atomization generator, and keep a certain liquid surface height. Adjust the ultrasonic frequency of the ultrasonic atomizing generator to 2.0MHz, turn on the power, and the ultrasonic atomizing generator starts to work, and instantly atomizes the paint into a very fine liquid mist with a particle size of 10um~30um, and reaches the double layer through the mist outlet tube Nozzle, under the action of oxygen flow, the liquid mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com