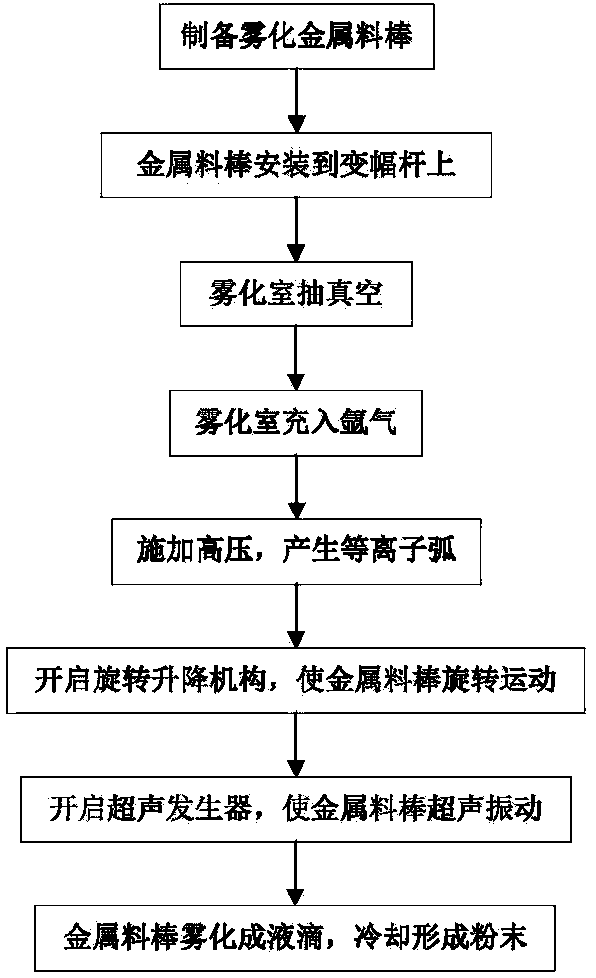

Ultrasonic atomization preparation device and method for spherical metal powder

A metal powder and ultrasonic atomization technology, which is applied to the ultrasonic atomization preparation device and preparation field of spherical metal powder, can solve the problems of unsuitable metal powder, cavitation corrosion, etc., and achieves narrow particle size distribution, high sphericity, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto, and for process parameters not specified in particular, conventional techniques can be referred to.

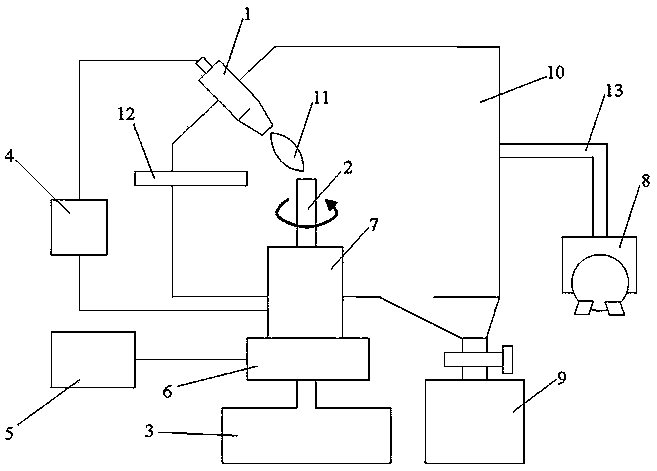

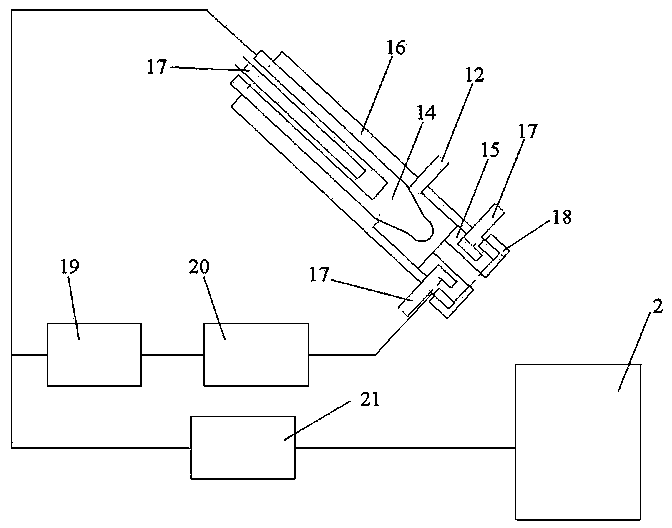

[0048] An ultrasonic atomization preparation device for spherical metal powder, combined with figure 2 , image 3 As shown, it includes a plasma arc generating system, an ultrasonic vibration system, a vacuum pump 8 and a powder collection cylinder 9 . The plasma arc generating system includes a plasma gun 1 , a metal rod 2 , a rotating lifting mechanism 3 and a main power supply 4 . The plasma gun 1 includes a cathode 14 , a nozzle 15 , a gun body 16 , an air pipe 12 , a water pipe 17 and a gland 18 . The metal rod 2 is used as an anode. The rotating lifting mechanism 3 realizes the rotating and lifting functions of the metal material rod 2 . The main power supply 4 includes a high frequency po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com