Buffer runner rhombic core model plastic hard tube extruder head

A technology of extruder and mandrel, which is applied in the field of pipe extruder head, buffer channel diamond-shaped mandrel plastic hard pipe extruder head, and can solve the problems of corrugated inner wall, uneven wall thickness and traction Slippage and other problems can be improved to improve the quality of products, improve the effect of plasticization, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

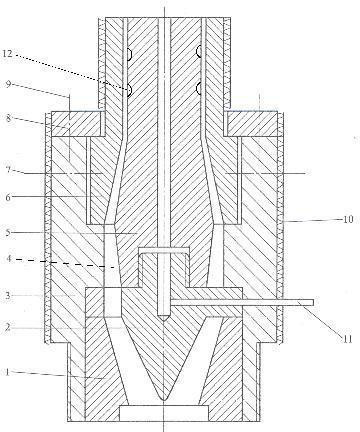

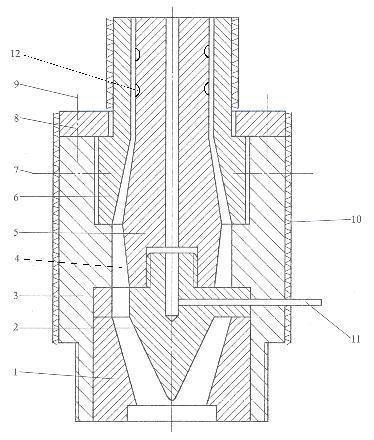

[0012] like figure 1 As shown, the head of the plastic hard pipe extruder with a diamond-shaped core mold in the buffer channel includes a pad 1, a flow divider 2, a mold body 3, a core mold 5, a die 6, and an air intake rod 11. The pad 1 , shunt 2, mold body 3, mandrel 5, and die 6 are combined to form a melt channel 4, and a heating ring 10 is provided on the outside of the mold body 3, and the mold body 3 and die 6 have adjustment screws 7 connection; the outside of the mold body 3 and the die 5 is provided with a gland 8, the gland 8 and the mold body 3 are connected by fixing screws 9, the core mold 5 is a diamond core mold, the Corresponding to the outlet end of the die 6, the mandrel 5 is provided with two concave arc-shaped buffer grooves 12 .

[0013] The invention is suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com