Molybdenum-based rare earth oxide powder metallurgical alloy wafer and preparing method thereof

A technology of rare earth alloy and rare earth powder, applied in the field of molybdenum-based rare earth powder metallurgy alloy disc and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

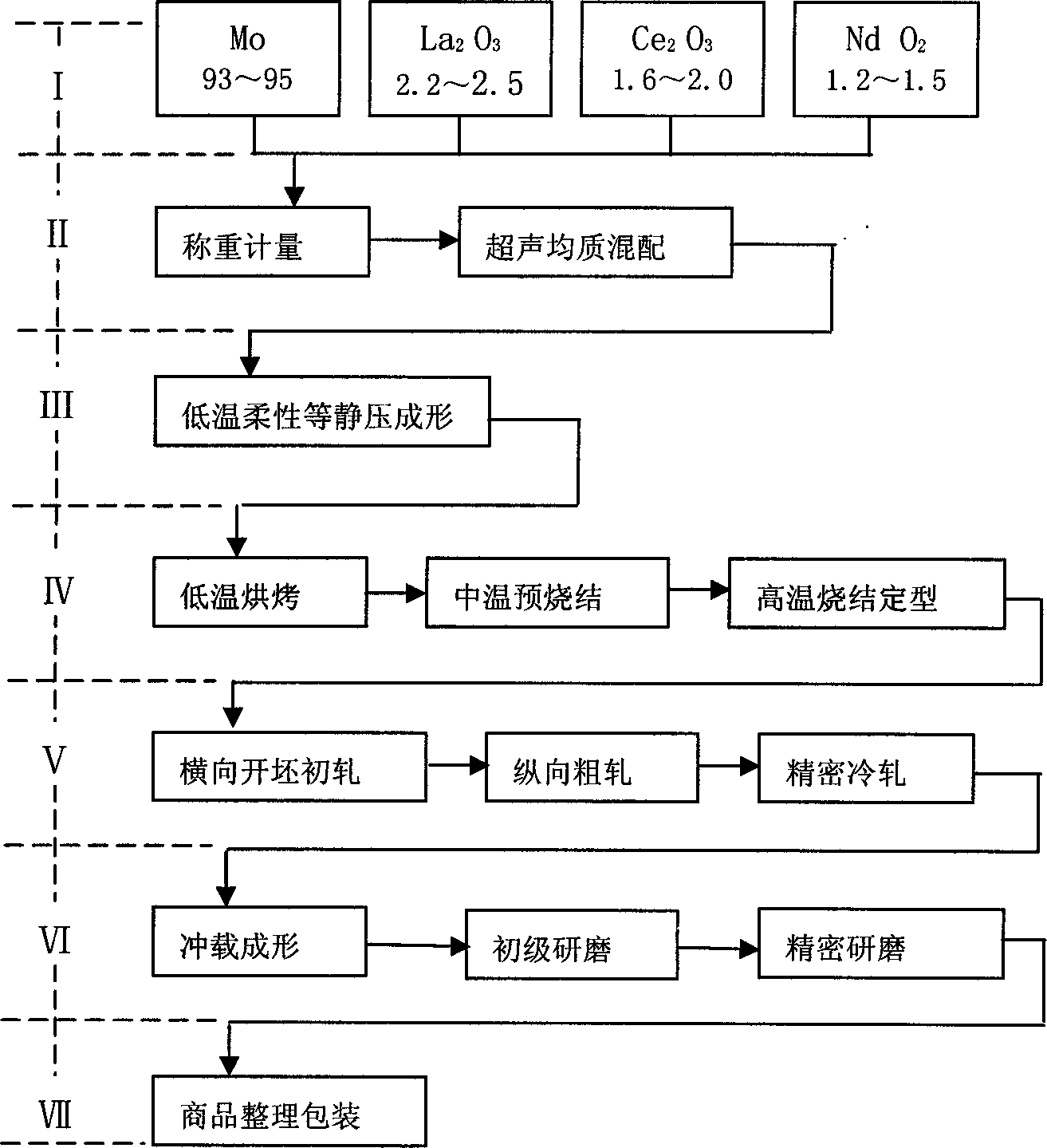

[0088] as attached figure 1 As shown, the molybdenum-based rare earth powder metallurgy alloy wafer and the preparation method thereof of the present invention include multi-component material ratio (I), ultrasonic homogeneous mixing (II), low-temperature flexible isostatic pressing (III), successive sintering and shaping (IV), grading and multi-pass rolling (V), fine processing (VI), commodity finishing and packaging (VII) 7 preparation technology units, and the technical equipment and technical parameters of their configuration.

[0089] as attached figure 1 As shown, the described multi-component material proportioning preparation technology unit (I) determines the proportioning ratio of various components of molybdenum-based rare earth powder metallurgy alloy discs, and manufactures molybdenum-based rare earth powder metallurgy alloy circles in batches The total weight of the sheet product is the base number, and the proportions of various ingredients are by weight: pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com