Bamboo recombination material hydraulic unit loading and mode pushing combination device

A technology of hydraulic unit and combined device, which is applied in the direction of veneer presses, plywood presses, wood processing equipment, etc., which can solve the problems of reduced production and operation efficiency, low degree of automation, waste of loading machine equipment, etc., and improve equipment utilization High efficiency, high degree of automation, and the effect of improving the quality of profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

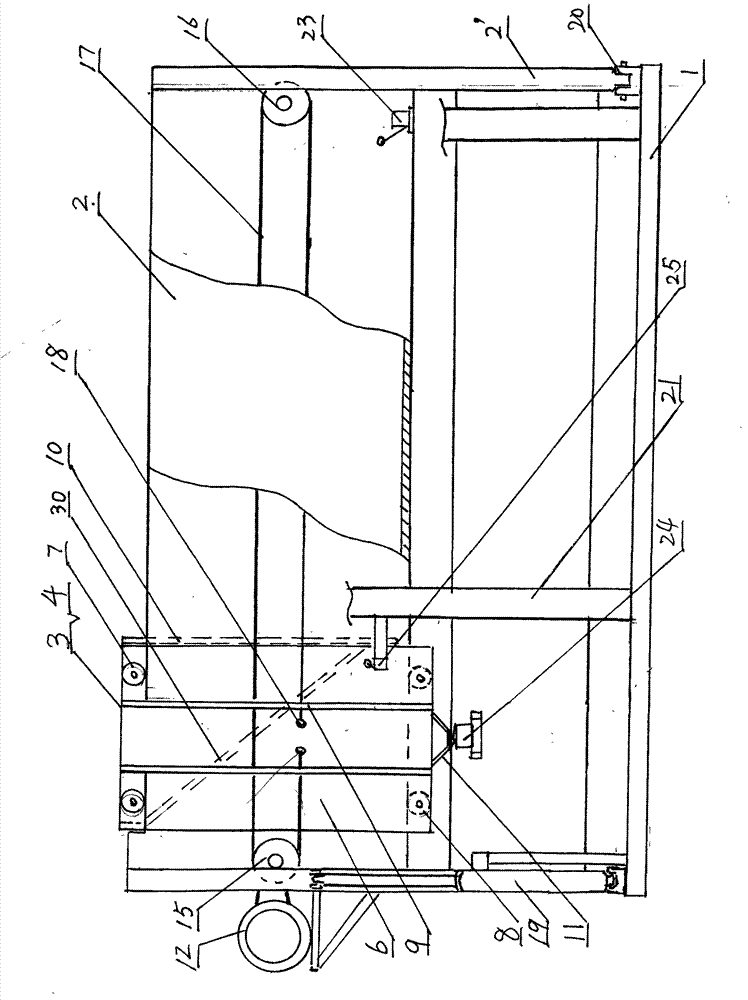

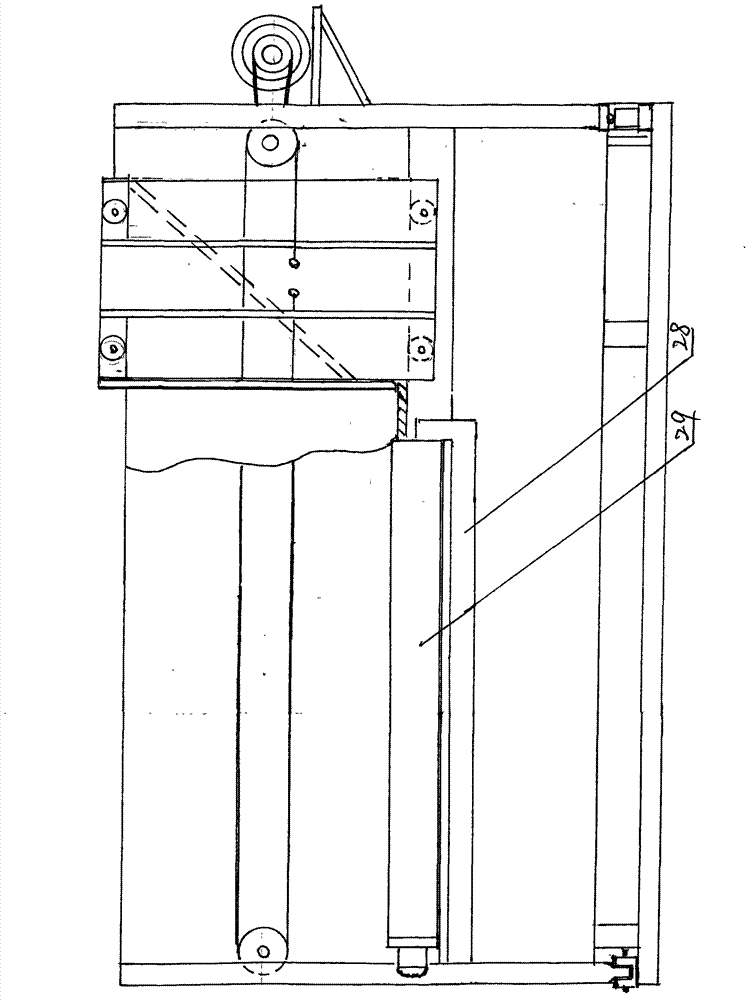

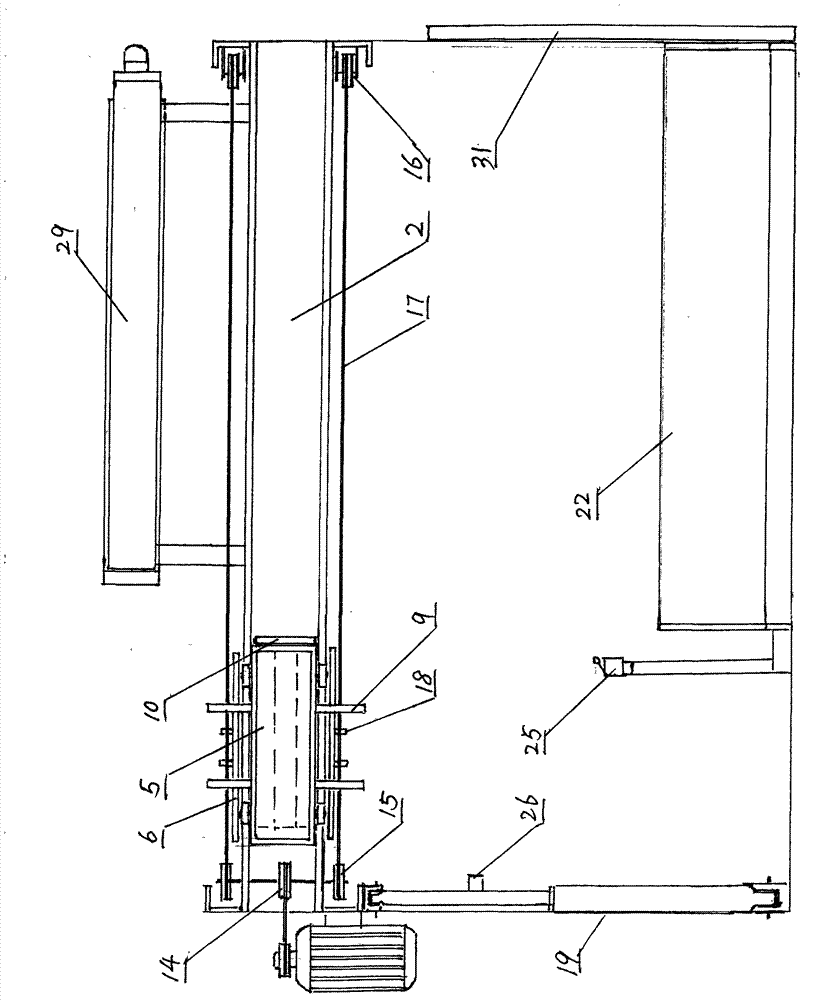

[0014] The specific embodiment is described in conjunction with the above-mentioned accompanying drawings.

[0015] The present invention relates to a bamboo and wood recombined wood hydraulic machine assembly material and mold pushing combination device as an auxiliary equipment of a press, which is arranged in front of the press, facing the mold cavity of the press, and the box opening at one end of the charging box is connected with the mold cavity of the press correspondingly.

[0016] The present invention comprises a base plate seat 1, a charging box 2, a pusher 3 and an electric control device. The charging box 2 is an upper opening box composed of two side plates and a bottom plate, and one end of the charging box connected to the cavity of the hydraulic press is open, and the charged material is pushed into the cavity of the press through this opening. The two ends of the charging box have a bottom bracket 2', and the bottom end of the bracket is hinged with the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com