Continuous slab cutting equipment and method thereof for cutting continuous slab

A slab and equipment technology, applied to continuous slab cutting equipment and its cutting field, can solve the problems of increasing power, shavings splashing everywhere, affecting the production and processing of slab quality, and achieving the effect of improving quality and avoiding shavings splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

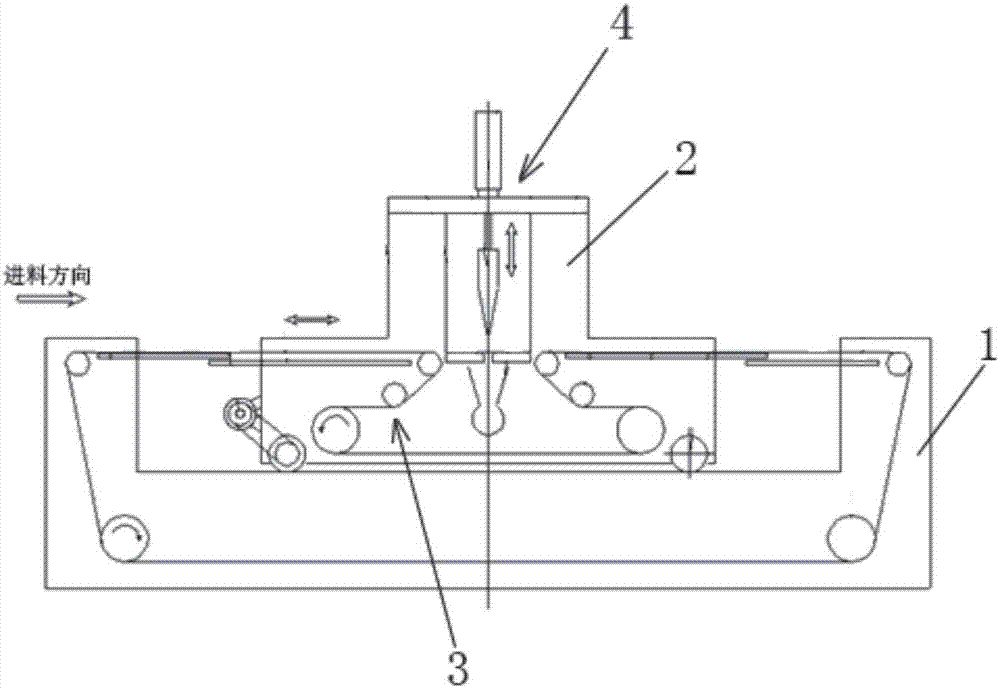

Image

Examples

Embodiment approach

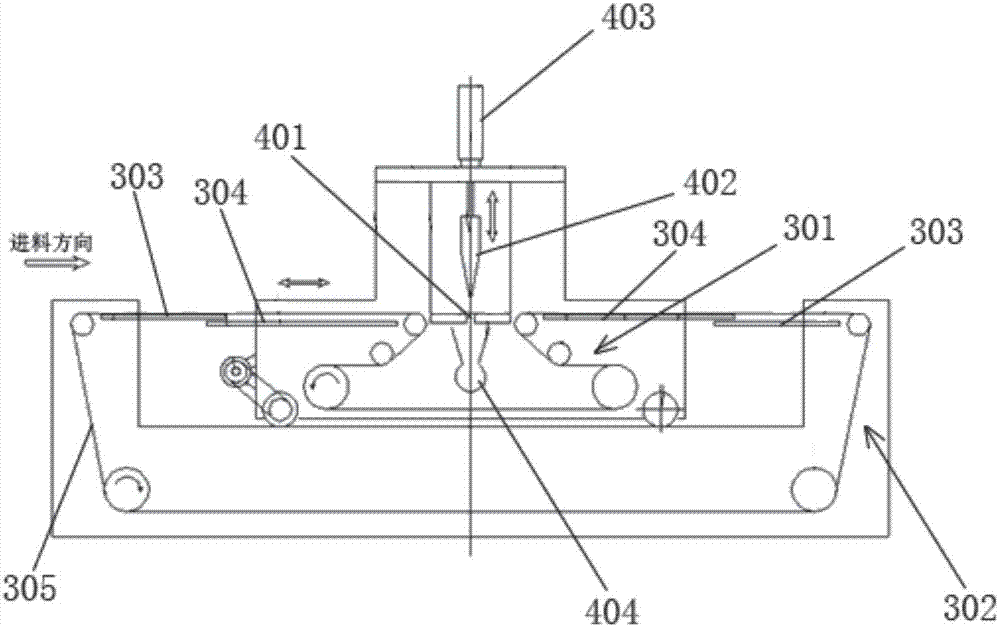

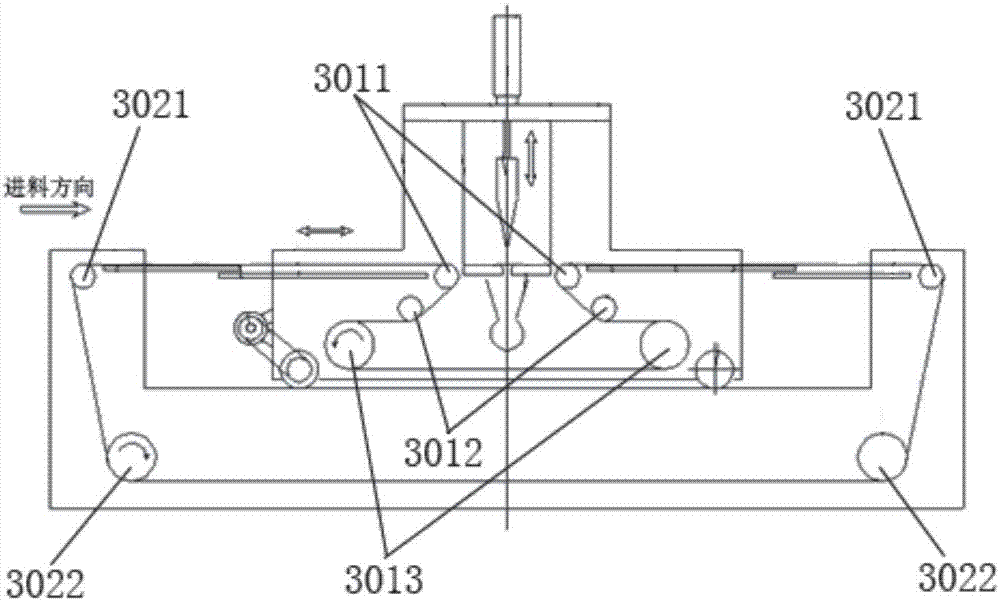

[0046] According to one embodiment of the present invention, as image 3 As shown, the transmission unit 3 includes two sets of moving rolls 301 and two sets of rolls 302. The moving reversing roller group 301 comprises two first moving reversing rollers 3011, two second moving reversing rollers 3012 and two the 3rd moving reversing rollers 3013. The set of deflection rolls 302 includes two first deflection rolls 3021 and two second deflection rolls 3022. Such as figure 2 As shown, the first moving reversing roller 3011, the second moving reversing roller 3012 and the third moving reversing roller 3013 are all arranged symmetrically about the central axis of the moving support 2. The first fixed redirecting roller 3021 and the second fixed redirecting roller 3022 are all arranged symmetrically about the central axis of the frame 1. Such setting can make the operation of the equipment more stable, the force of the equipment can be even, and also make the structural arrangem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com