Production method of fresh wet rice noodles

A technology of fresh and wet rice noodles, applied in the field of grain processing, which can solve the problems of starch aging quality, slow aging and decline of fresh and wet rice noodles, etc., and achieve the effects of improving sensory quality, improving anti-aging effect, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

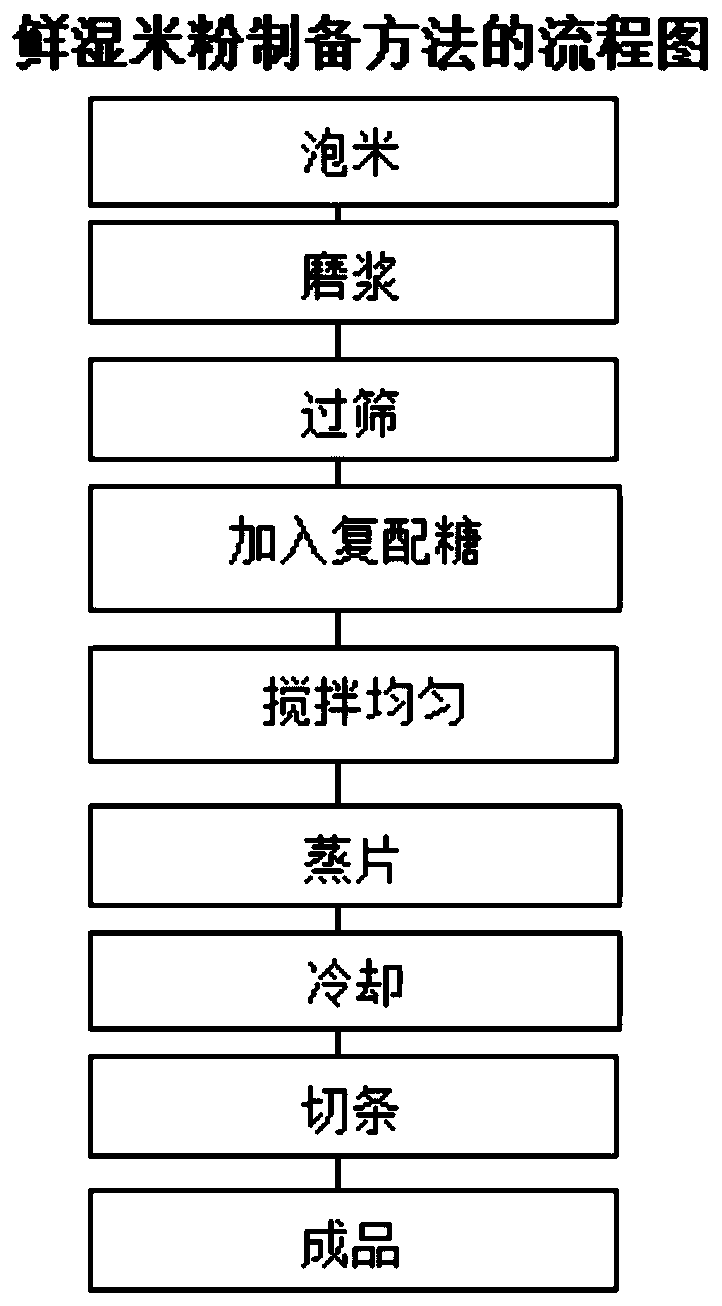

[0021] First aspect, the present invention provides a kind of preparation method of fresh wet rice flour, comprises the following steps:

[0022] (1) After the rice is soaked in water, it is refined and sieved to obtain rice milk;

[0023] (2) mixing the rice milk obtained in step (1) with compound sugar and stirring evenly to obtain a slurry;

[0024] (3) the slurry obtained in step (2) is steamed, cooled, and cut into strips to obtain the fresh wet rice noodles;

[0025] Wherein, the complex sugar includes at least two of trehalose, glucose, sucrose and xylitol.

[0026] Preferably, the compound sugar includes trehalose and glucose, and the mass ratio of trehalose and glucose is 1-3:1.

[0027] Preferably, the mass ratio of the compound sugar to rice is 3-9:100.

[0028] Preferably, the rice in step (1) is obtained from rice raw materials through washing, sand removal and stone removal.

[0029] Preferably, the mass ratio of rice to water in step (1) is 1:1.5-2.5, and th...

Embodiment 1

[0035] (1) Clean the indica rice used for making rice noodles, remove sand and stone, soak 10 kg of rice with 20 kg of water for 6 hours, pour it into a colloid mill for grinding for 3 minutes, and then pass through a 60-mesh sieve to obtain rice milk;

[0036] (2) Mix the rice milk obtained in step (1) with 0.4kg trehalose and 0.2kg glucose and stir evenly to obtain a slurry;

[0037] (3) Spread the slurry obtained in step (2) evenly on the steaming plate and steam the slices for 120 seconds, take out the steamed rice slices and quickly put them in cold water to cool to room temperature, dry the surface moisture and wrap them with plastic wrap , and then cut the rice flakes into fresh wet rice noodles with a width of about 1cm.

Embodiment 2

[0039] (1) Clean the indica rice used for making rice noodles, remove sand and stone, soak 10kg of rice with 25kg of water for 8 hours, pour it into a colloid mill and refine it for 4 minutes, and then pass through an 80-mesh sieve to obtain rice milk;

[0040] (2) Mix the rice milk obtained in step (1) with 0.6kg trehalose and 0.2kg glucose and stir evenly to obtain a slurry;

[0041] (3) Spread the slurry obtained in step (2) evenly on the steaming plate and steam the slices for 130 seconds, take out the steamed rice slices and quickly put them in cold water to cool to room temperature, dry the surface moisture and wrap them with plastic wrap , and then cut the rice flakes into fresh wet rice noodles with a width of about 1cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com