Method for improving gel strength of fibrillin and application of method

A technology of myofibrillar protein and gel strength, applied in the application, animal protein processing, vegetable protein processing and other directions, can solve the problems of instability and poor quality of meat products, achieve convenient operation, improve texture quality, improve The effect of gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

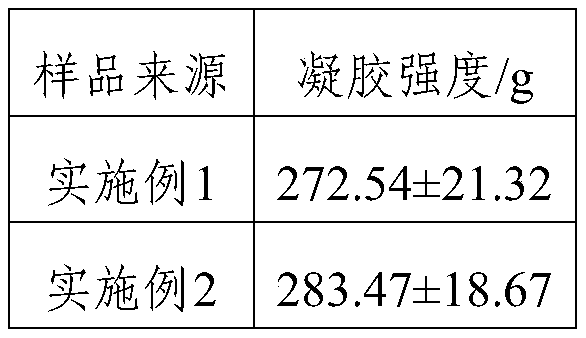

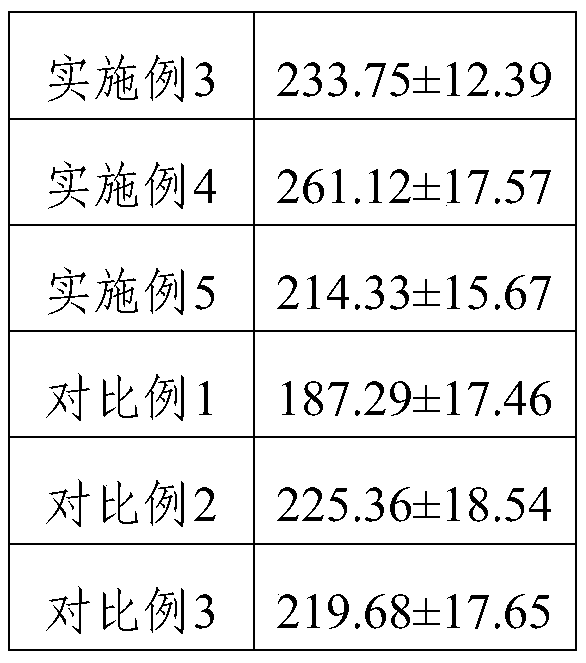

Examples

Embodiment 1

[0038] The present embodiment provides a kind of method that promotes pork myofibrillar protein gel strength, specifically:

[0039] (1) The myofibrillar protein extracted from fresh pork and the gel-type soybean protein isolate are compounded in a 0.6M sodium chloride solution according to the mass ratio of 9:1, and cut at a speed of 15000r / min. Cut and mix to form a complex protein colloid;

[0040] (2) Add 8wt% olive oil and 2wt% wheat bran enzymatic hydrolyzate to the composite protein colloid, and shear and mix at a speed of 15000r / min to form a blended emulsion;

[0041] (3) Add the blended emulsion into a glass cup with a diameter of 20mm and a height of 50mm, and prepare a thermal gel by means of segmented gradient heating; in the segmented gradient heating, the heating rate is 3°C / min, the temperatures of the four gradients are 40°C, 60°C, 75°C, and 90°C respectively, and the holding time of each gradient is 5min. The hot gel was rapidly cooled to room temperature ...

Embodiment 2

[0043] The present embodiment provides a kind of method that promotes beef myofibrillar protein gel strength, specifically:

[0044] (1) Compound myofibrillar protein extracted from fresh beef and gel-type soybean protein isolate in 0.6M sodium chloride solution according to the mass ratio of 15:1, and cut at a speed of 15000r / min Cut and mix to form a complex protein colloid;

[0045] (2) Add 10wt% rapeseed oil and 3wt% wheat bran enzymatic hydrolyzate to the composite protein colloid, shear and mix at 15000r / min to form a blended emulsion;

[0046] (3) The blended emulsion is prepared by means of segmental gradient heating to prepare thermal gel; in the segmental gradient heating, the heating rate is 3°C / min, and the temperatures of the four gradients are 40°C, 60°C, 75°C, 90°C, and the holding time of each gradient is 7min. The hot gel was rapidly cooled to room temperature under running water to obtain a strong myofibrillar protein gel.

Embodiment 3

[0048] The present embodiment provides a kind of method that promotes chicken myofibrillar protein gel strength, specifically:

[0049] (1) The myofibrillar protein extracted from fresh chicken and the gel-type soybean protein isolate are compounded in a 0.6M sodium chloride solution according to the mass ratio of 20:1, and cut at a speed of 15000r / min. Cut and mix to form a complex protein colloid;

[0050] (2) Add 12wt% soybean oil and 4wt% wheat bran enzymatic hydrolyzate to the composite protein colloid, shear and mix at 15000r / min to form a blended emulsion;

[0051] (3) The blended emulsion is prepared by means of segmental gradient heating to prepare thermal gel; in the segmental gradient heating, the heating rate is 3°C / min, and the temperatures of the four gradients are 40°C, 60°C, 75°C, 90°C, the holding time of each gradient is 3min. The hot gel was rapidly cooled to room temperature under running water to obtain a strong myofibrillar protein gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com