High-performance Al-Mg-Si alloy and preparation method thereof

An al-mg-si, high-performance technology, applied in the field of high-performance Al-Mg-Si alloy and its preparation, can solve the problems of low mechanical properties of alloy materials, low production efficiency, complex process, etc., and achieve high yield strength. , The effect of reducing process cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

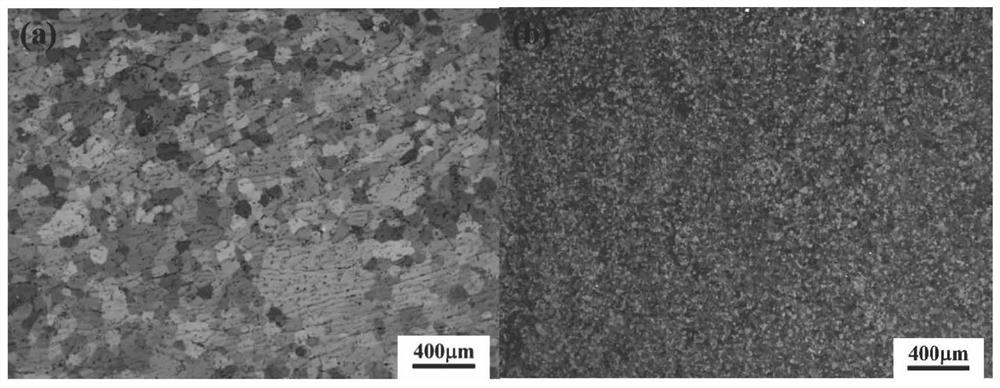

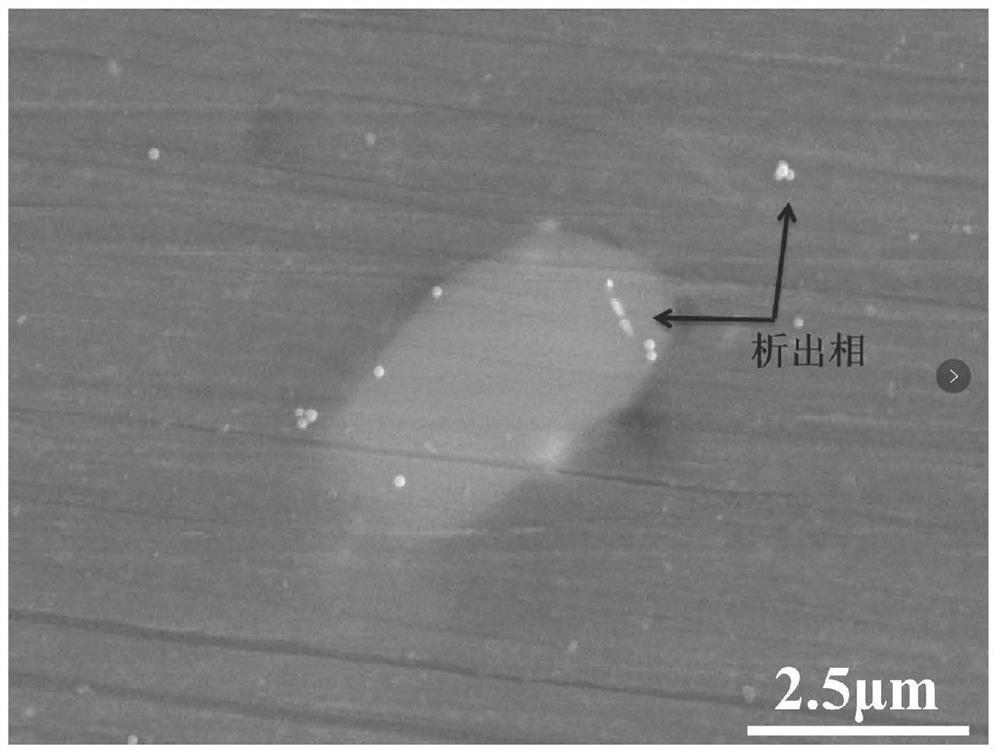

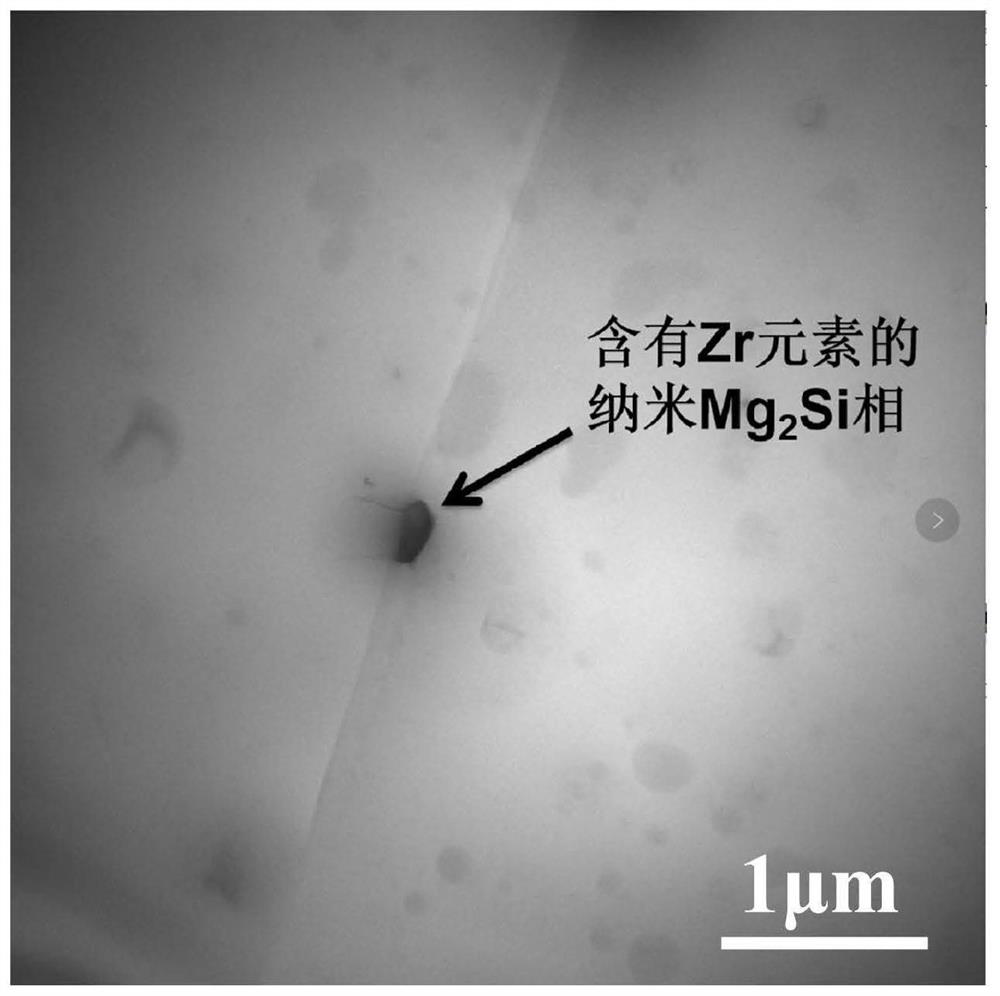

Image

Examples

Embodiment 1

[0032] Al-Mg-Si alloy, described alloy is made up of following composition by mass percentage:

[0033] Mg: 0.5%; Si: 1.0%; Fe: 0.2%; Ti: 0.1%; Zr: 0.1%; the sum of unavoidable impurities ≤ 0.15%; the rest is Al; the above Al-Mg-Si alloy, the preparation method is as follows:

[0034] (1) Add 99.98% industrial pure aluminum ingots, pure magnesium, Al-Si master alloy, Al-Ti master alloy and Al-Zr master alloy to the melting furnace in turn and heat and melt at 750°C until the raw materials are stirred After melting, the alloy melt was obtained after blowing in argon gas for 10 minutes;

[0035] (2) Drain the alloy melt obtained in step (1) into the gap of the water-cooled copper roll for casting and rolling. The roll diameter of the water-cooled copper roll is Φ260mm, the thickness of the roll sleeve is 20mm, and the gap distance between the rolls is 4.5mm. The linear speed is 65mm / s, and the casting and rolling slab of sub-rapid solidification alloy is obtained, and the thick...

Embodiment 2

[0039] Al-Mg-Si alloy, described alloy is made up of following composition by mass percentage:

[0040] Mg: 0.7%; Si: 1.2%; Fe: 0.17%; Ti: 0.05%; Zr: 0.05%; the sum of unavoidable impurities ≤ 0.15%; the rest is Al; the above Al-Mg-Si alloy, the preparation method is as follows:

[0041] (1) Add 99.98% industrial pure aluminum ingots, pure magnesium, Al-Si master alloy, Al-Ti master alloy and Al-Zr master alloy to the melting furnace in turn and heat and melt at 750°C until the raw materials are stirred After melting, the alloy melt was obtained after blowing in argon for 12 minutes;

[0042] (2) the alloy melt obtained in step (1) is drained into the gap of the water-cooled copper roll for casting and rolling. The roll diameter of the water-cooled copper roll is Φ270mm, the thickness of the roll sleeve is 23mm, and the gap distance between the rolls is 4mm. The line speed is 70mm / s, and the sub-rapid solidification alloy cast-rolled billet is obtained, and the thickness of t...

Embodiment 3

[0046] Al-Mg-Si alloy, described alloy is made up of following composition by mass percentage:

[0047]Mg: 0.75%; Si: 1.3%; Fe: 0.17%; Ti: 0.15%; Zr: 0.15%; the sum of unavoidable impurities ≤ 0.15%; the rest is Al; the above Al-Mg-Si alloy, the preparation method is as follows:

[0048] (1) Add 99.98% industrial pure aluminum ingots, pure magnesium, Al-Si master alloy, Al-Ti master alloy and Al-Zr master alloy to the melting furnace in turn and heat and melt at 750°C until the raw materials are stirred After melting, the alloy melt was obtained after blowing in argon for 14 minutes;

[0049] (2) drain the alloy melt obtained in step (1) into the gap of the water-cooled copper roll for casting and rolling. The roll diameter of the water-cooled copper roll is Φ300mm, the thickness of the roll sleeve is 27mm, and the gap distance between the rolls is 7mm. The line speed is 42mm / s, and the sub-rapid solidification alloy cast-rolled slab is obtained, and the thickness of the cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com