Straw drying warehouse

A straw and bin technology, applied in the field of energy-saving equipment, can solve problems such as hindering spring sowing, affecting navigation, causing fires, etc., and achieve the effect of avoiding mold and good ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

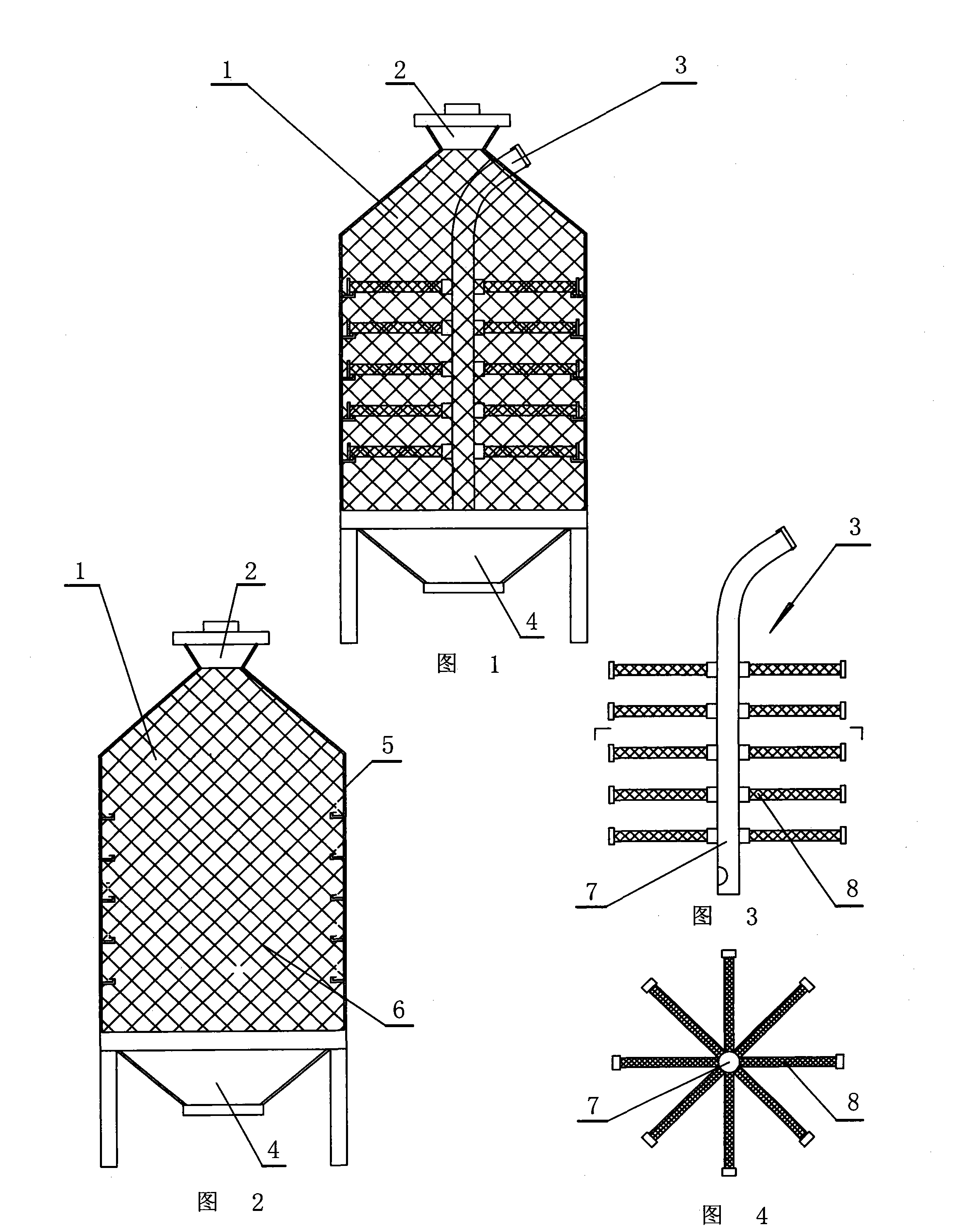

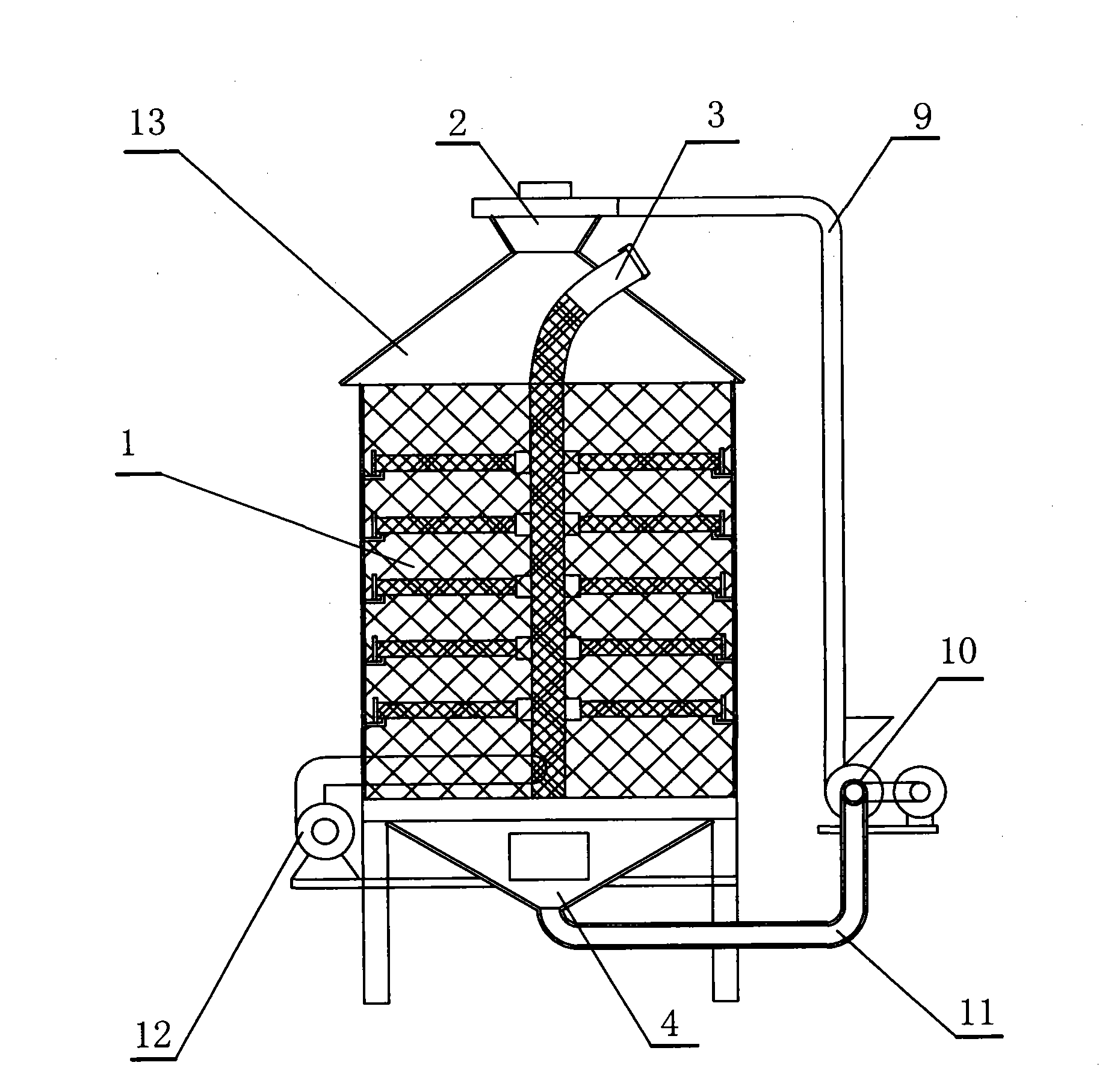

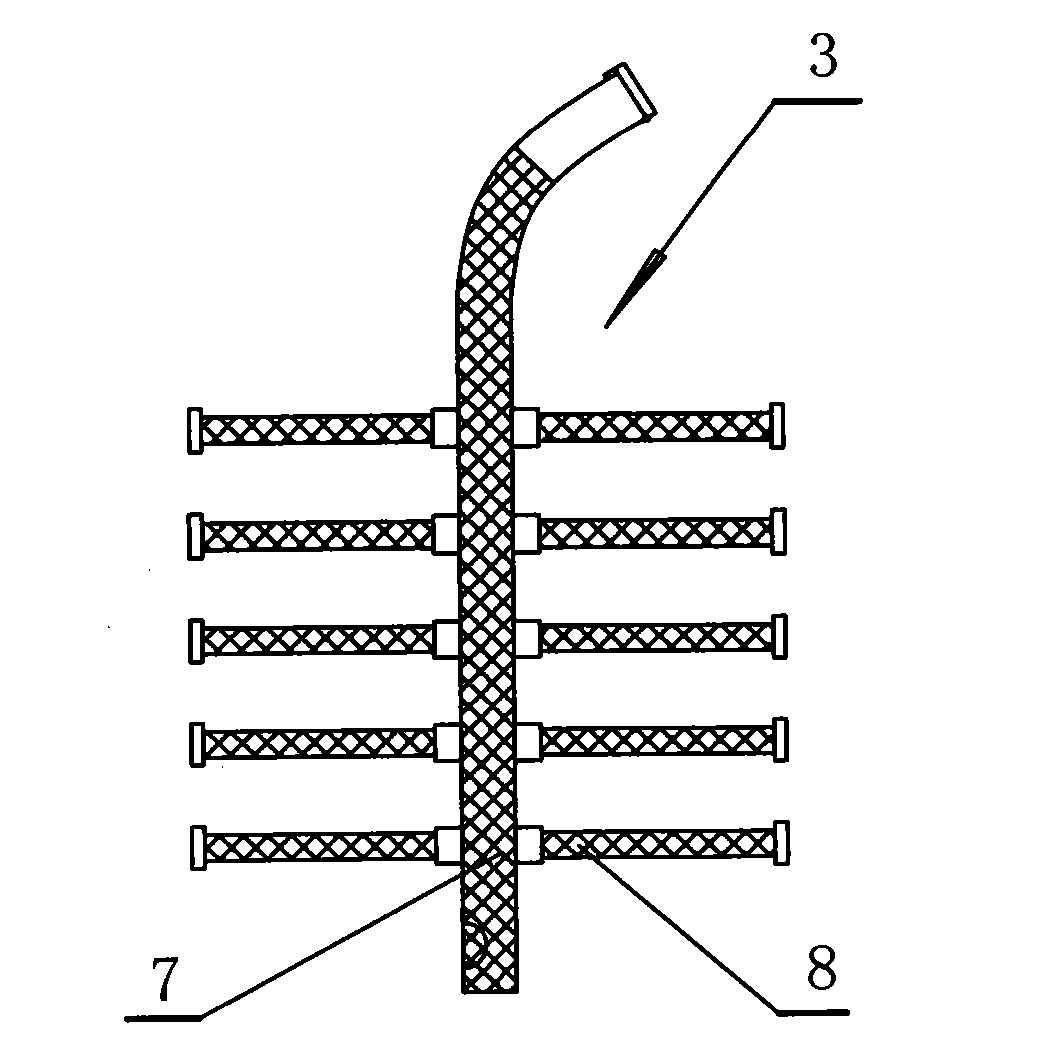

[0028] The first example: as figure 1 , 2 As shown, the main body of this straw fuel air-drying bin is a cylindrical bin body 1, the upper end of the bin body 1 is provided with a feeding port 2, and the bin body 1 is provided with a plurality of ventilation pipes 3. combine figure 2 It can be seen that the silo body 1 is surrounded by a frame 5 and a screen 6, and the mesh size is determined by the length of the straw. If the straw is 10cm long, the mesh diameter is 8-12cm. Of course, the size of the sieve hole has a great relationship with the state of the straw and the rate of entering the bin body. On the contrary, the sieve hole should be larger. For the straws that stick to each other, the diameter of the sieve holes can be dozens of times larger than the length of the cut straws. The capacity of the silo body 1 can be large or small, and the experimental prototype can reach 500m 3 Above, because the weight is very small, and it can be assembled on site, the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com