Drying device suitable for food and food drying method thereof

A drying device and food technology, applied in the fields of food preservation, application, food science, etc., can solve the problems of temperature and humidity that cannot be adjusted in the drying process, and achieve the effects of controllable drying quality, good temperature and humidity uniformity, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

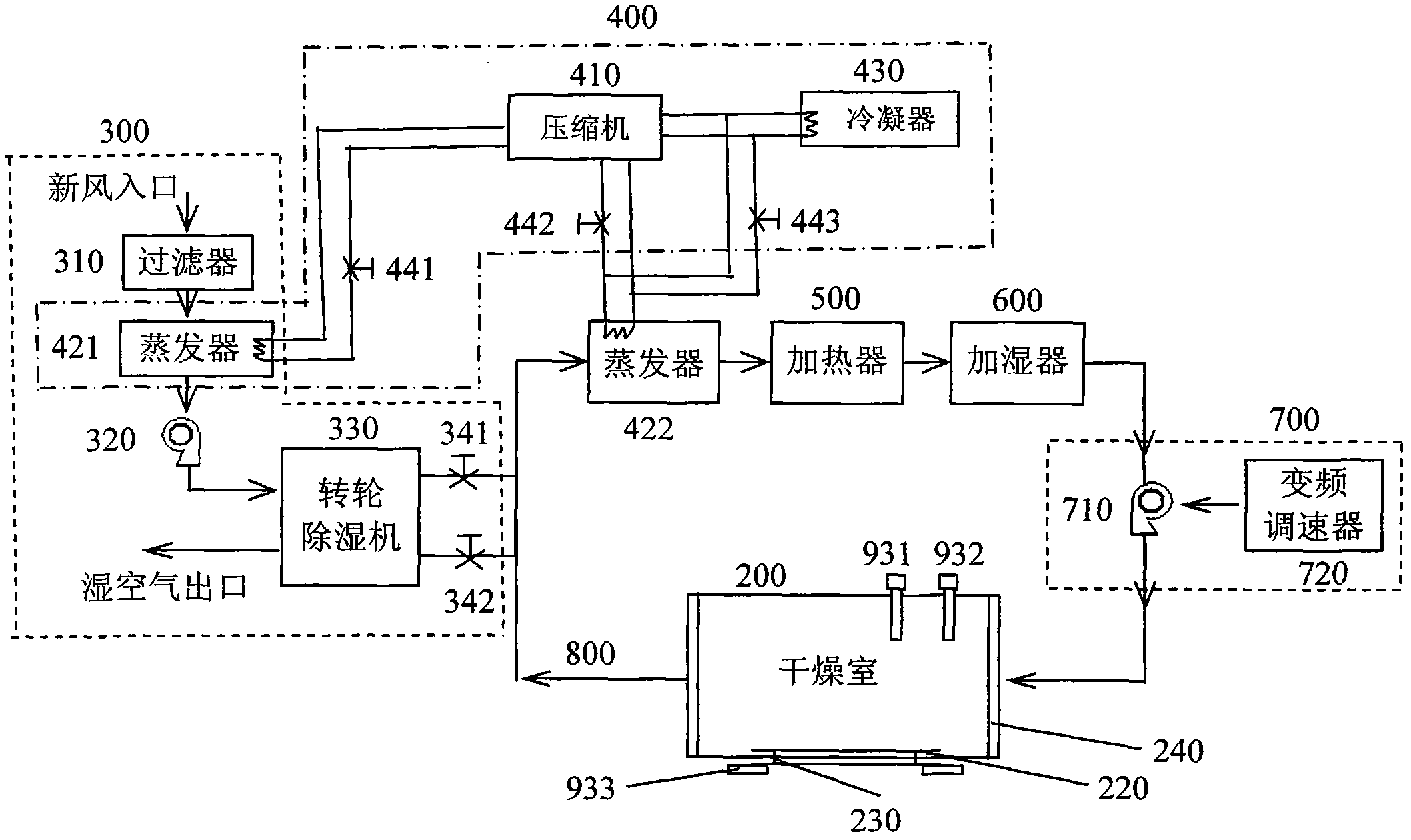

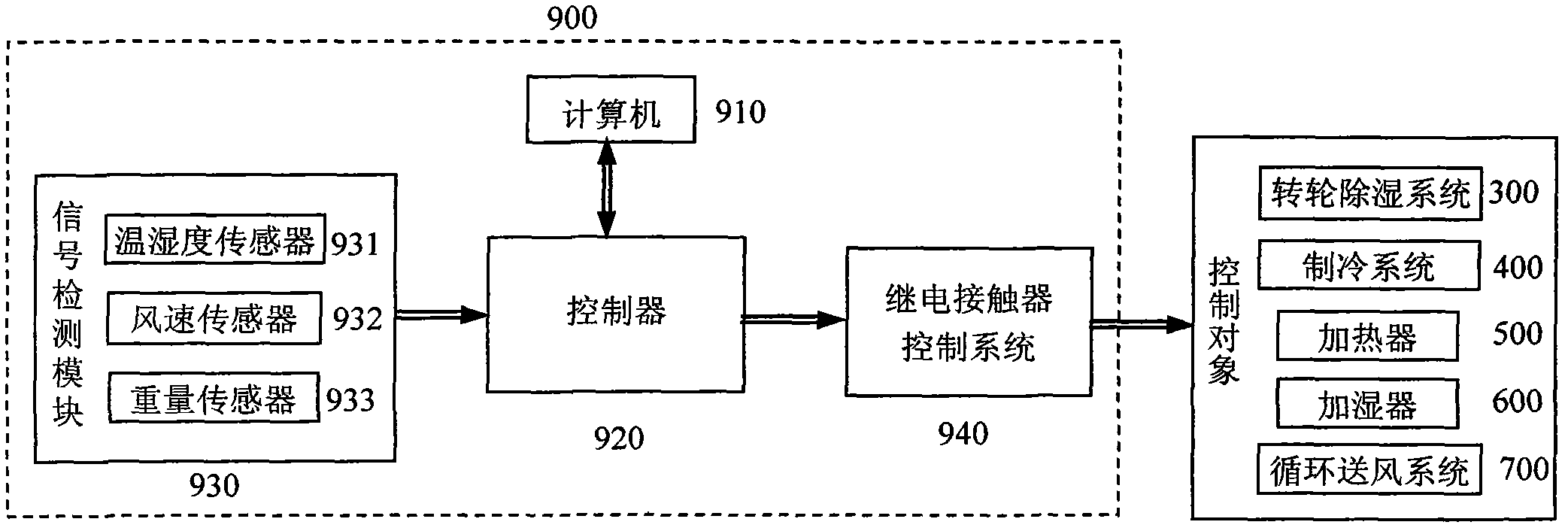

[0053] Depend on Figure 1-Figure 2 As shown, the applicant has designed a drying device suitable for food, which includes a drying chamber (200), a wheel dehumidification system (300), a refrigeration system (400), a heater (500), a humidifier (600), Circulating air supply system (700), main air path (800) and control system (900);

[0054] The drying chamber (200), the refrigeration system evaporator (422), the heater (500), the humidifier (600), and the circulating air supply system (700) are sequentially connected through air ducts to form a main air path (800);

[0055] The runner dehumidification system (300) is connected in parallel with the main air path (800);

[0056] The circulating air supply system (700) includes a circulating fan (710) and a frequency converter (720), and the circulating fan is connected to the frequency converter in sequence.

[0057] Described drying chamber (200) comprises casing (210), weighing tray (220) and weighing tray support (230);

...

Embodiment 2

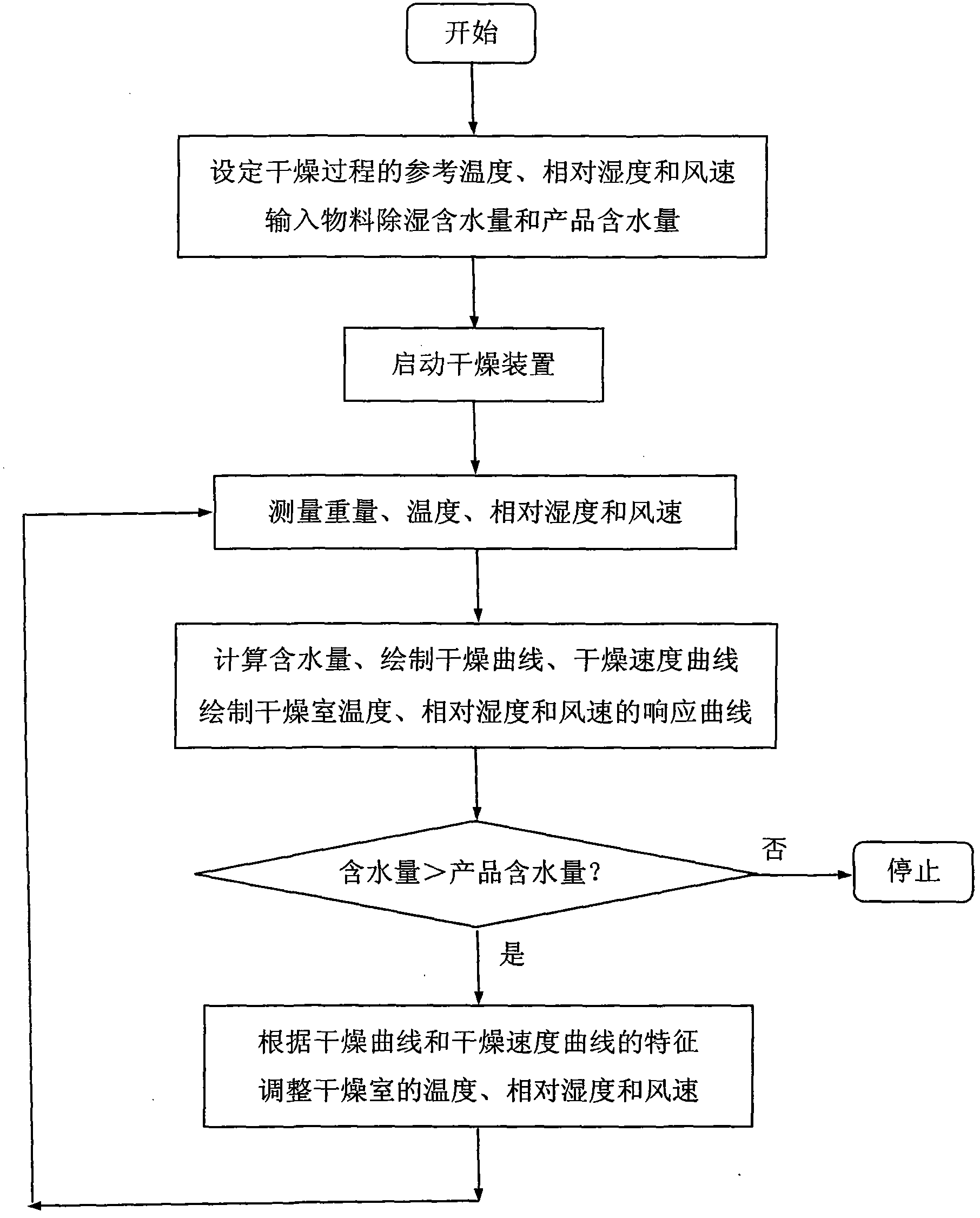

[0073] Utilize the method for dry food of device described in embodiment 1, its steps are as follows:

[0074] (1) Place the food to be dried in the drying room;

[0075] (2) Set the reference temperature, relative humidity, wind speed, initial moisture content of the material and product moisture content in the drying process;

[0076] (3) Real-time detection of weight, temperature, relative humidity, and wind speed, calculation of water content, and drawing of drying curves, drying speed curves, temperature and humidity, and wind speed response curves;

[0077] (4) According to the characteristics of the drying curve and drying speed curve, adjust the drying room temperature, relative humidity and wind speed;

[0078] (5) compare the actual moisture content with the moisture content of the product, and determine whether to end the drying process by the controller (920);

[0079] (6) Use the temperature and humidity sensor (931) to detect the actual temperature and relative...

Embodiment 3

[0092] Embodiment 3 (application embodiment):

[0093] 1. No-load test

[0094] The device of the embodiment was used to conduct a no-load test, and the temperature and humidity response curve of the device was tested under the no-load condition. Figure 4 It is a high temperature and high humidity test, the temperature and humidity response curve when the temperature is set at 80°C and the relative humidity is set at 70%. Figure 5 It is a low temperature and low humidity test, the temperature and humidity response curve when the temperature is set at 5°C and the relative humidity is set at 20%. Figure 6 is the response curve when the wind speed is set to 2m / s. Table 1 is the control performance analysis under different temperature and humidity.

[0095] Table 1 Performance analysis of control under different temperature and humidity

[0096]

[0097] 2. Material drying test

[0098] This device is used for material drying test, and the material is Li bean pods.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com