Food desiccant and preparation method thereof

A food drying and adhesive technology, applied in food preservation, food science, application, etc., can solve the problems of single function and toxicity of desiccant, achieve remarkable drying effect, prevent oxidative deterioration, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

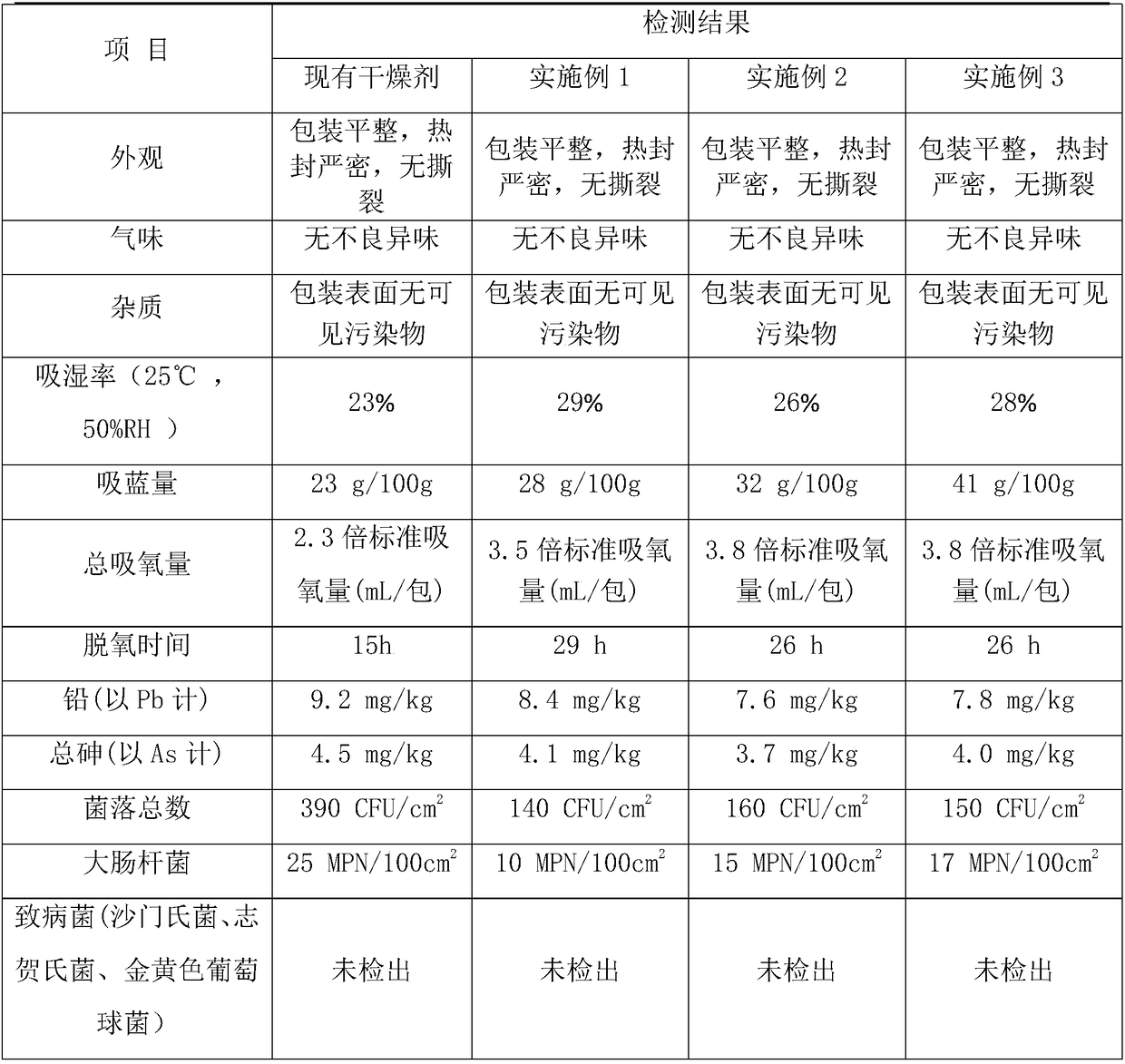

Examples

Embodiment 1

[0026] A food desiccant comprising the following components by weight:

[0027] 30 parts of acrylonitrile grafted starch, 4 parts of calcium chloride, 2 parts of iron powder, 1 part of powdered activated carbon, 0.1 part of sodium dehydroacetate and 0.1 part of hydroxypropyl cellulose.

[0028] Among them, the particle diameters of iron powder and powdered activated carbon are both 40 mesh.

[0029] The preparation method of above-mentioned food desiccant, comprises the following steps:

[0030] (1) the acrylonitrile grafted starch is pulverized to a particle diameter of 40 orders, and then mixed with calcium chloride and iron powder;

[0031] (2) Continue to add powdered activated carbon, sodium dehydroacetate and hydroxypropyl cellulose, mix, then add water and stir, granulate and shape, dry at 0.1MPa and 100°C, cool to room temperature, and finally seal the bag. A safe and environment-friendly food desiccant is prepared.

Embodiment 2

[0033] A food desiccant comprising the following components by weight:

[0034] 20 parts of sodium polyacrylate, 6 parts of calcium chloride, 3 parts of iron powder, 1 part of powdered activated carbon, 0.2 part of sodium dehydroacetate and 0.1 part of ethyl cellulose.

[0035] The preparation method of above-mentioned food desiccant, comprises the following steps:

[0036] Among them, the particle diameters of iron powder and powdered activated carbon are both 40 mesh.

[0037] (1) Sodium polyacrylate is crushed to a particle size of 40 mesh, then mixed with calcium chloride and iron powder;

[0038] (2) Continue to add powdered activated carbon, sodium dehydroacetate and ethyl cellulose, mix, then add water and stir, granulate and shape, dry at -0.1MPa, 90°C, cool to room temperature, and finally seal the bag. A safe and environment-friendly food desiccant is prepared.

Embodiment 3

[0040] A food desiccant comprising the following components by weight:

[0041] 25 parts of sodium polyacrylate, 6 parts of calcium chloride, 3 parts of iron powder, 2 parts of powdered activated carbon, 0.3 part of sodium propionate and 0.1 part of sodium carboxymethyl cellulose.

[0042] The preparation method of above-mentioned food desiccant, comprises the following steps:

[0043] Among them, the particle diameters of iron powder and powdered activated carbon are both 40 mesh.

[0044] (1) Sodium polyacrylate is crushed to a particle size of 40 mesh, then mixed with calcium chloride and iron powder;

[0045] (2) Continue to add powdered activated carbon, sodium dehydroacetate and ethyl cellulose, mix, then add water and stir, granulate and shape, dry at -0.08MPa, 80°C, cool to room temperature, and finally seal the bag. A safe and environment-friendly food desiccant is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com