Device and method for drying food by supercritical carbon dioxide

A carbon dioxide, drying food technology, applied in the direction of food preservation, food processing, dry preservation of meat/fish, etc., can solve the problems of long time hot air drying, low food porosity, high energy consumption, etc., to improve the technical content and product additional value, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

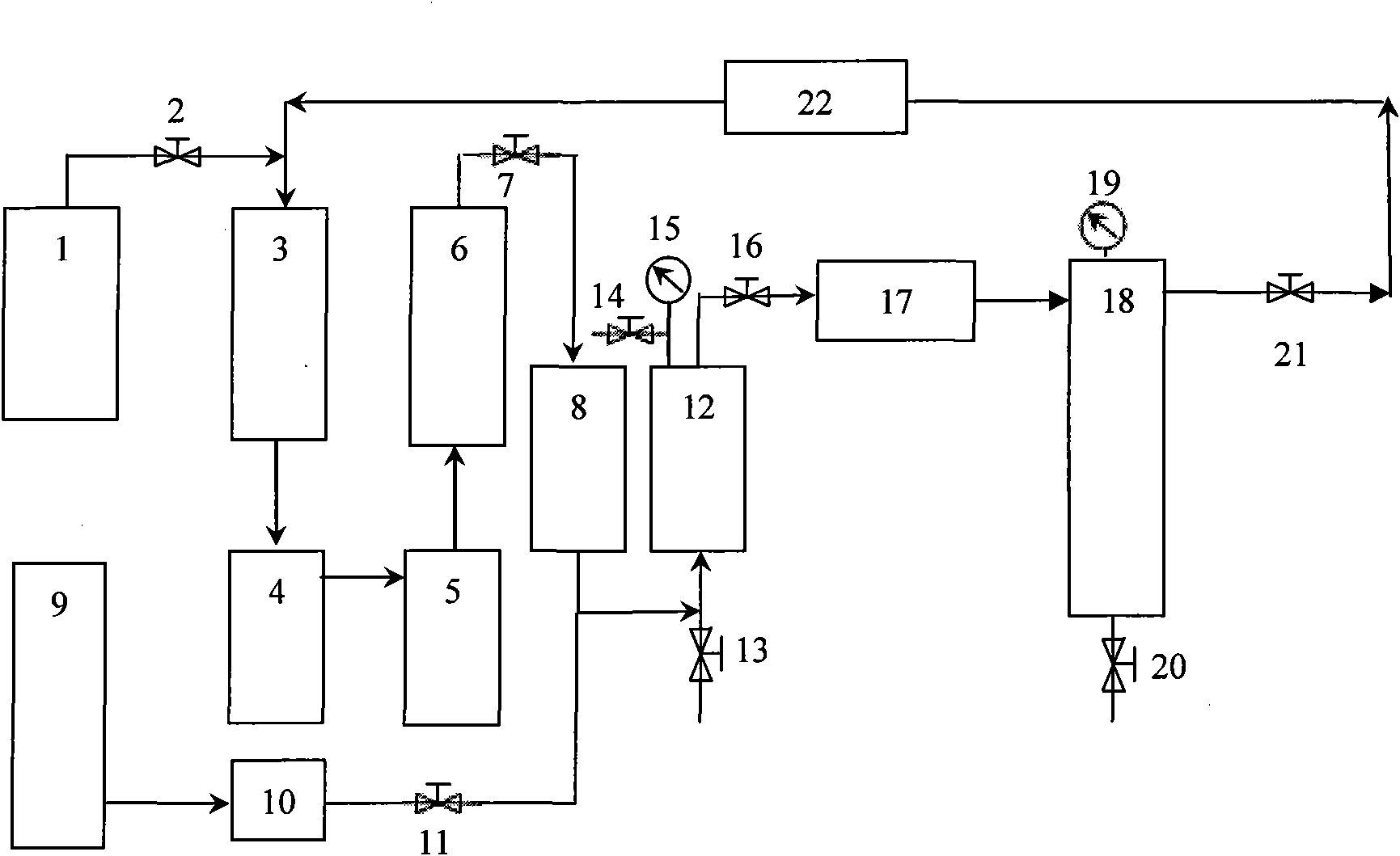

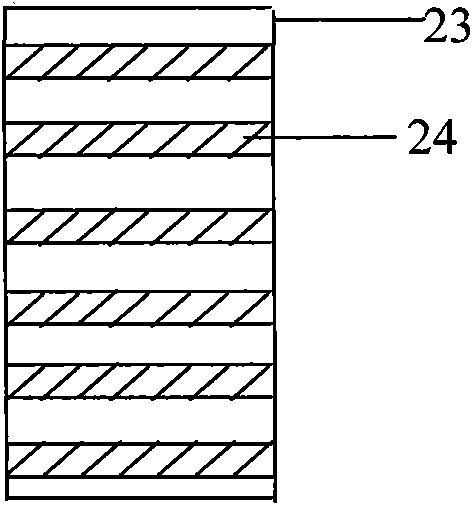

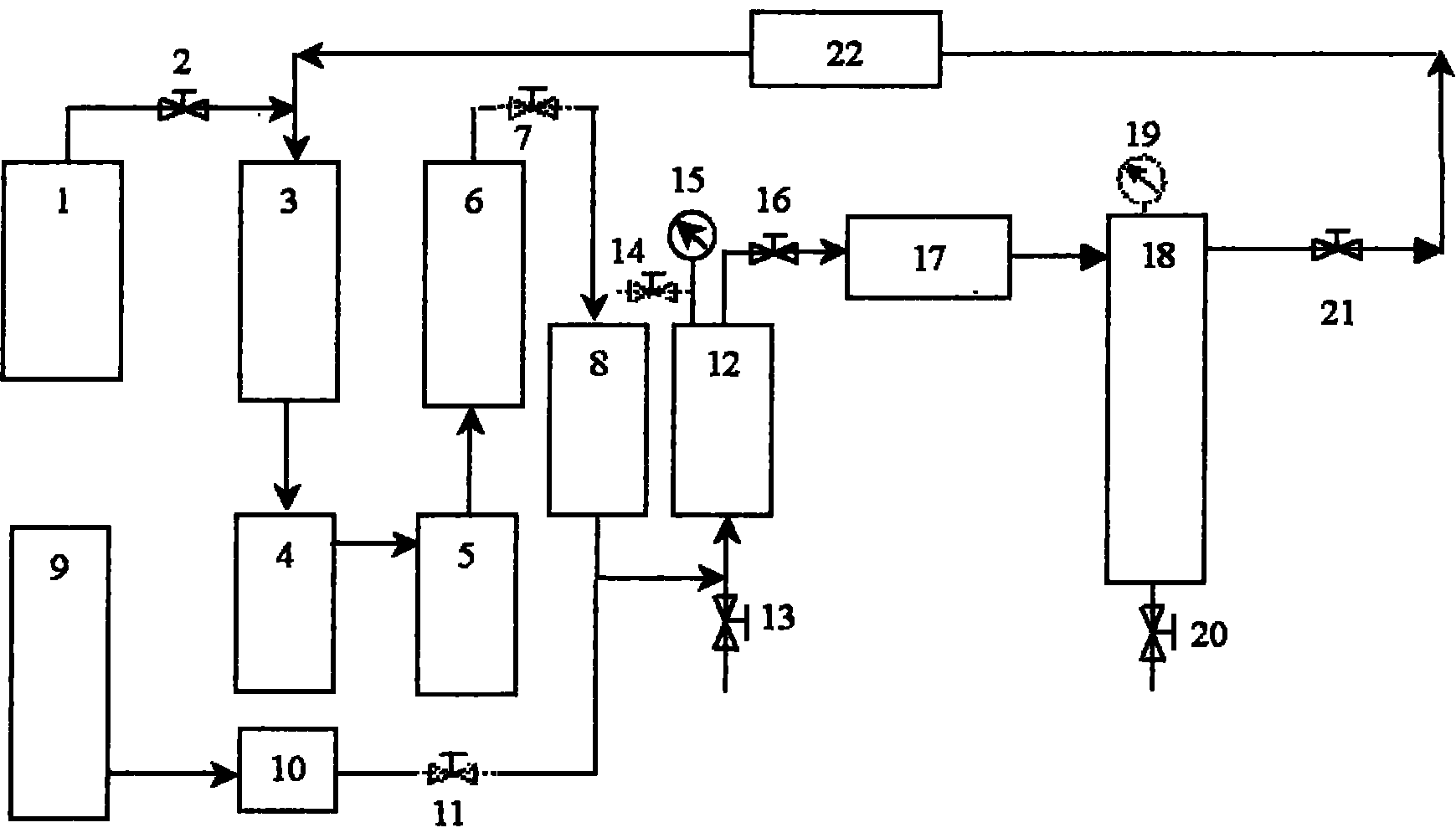

[0015] Before drying starts, first turn on the refrigeration system to reduce the temperature of the circulating water of the cooling device to about 0°C, turn on the heater I8 to raise the temperature of the drying chamber 12 to 50°C, turn on the heater II17 to raise the temperature of the desiccant reaction chamber 18 to 30°C; then cut carrot slices into cylinders with a thickness of 0.3 cm and a diameter of 3 cm, place it on the stainless steel wire mesh 24 of the drying chamber 12, then seal the drying chamber 12; open valve I2, valve II7, and close valve III11 , Valve VI16, feed dry carbon dioxide into the drying chamber 12, open the valve V14, discharge the residual air in the drying chamber 12 and then close the valve V14; then the pressure of the drying chamber 12 is raised to 20MPa by the high-pressure pump 5; open the valve VI16 , valve VII21, close valve VII20, and the drying process begins. During the drying process, the constant pressure of the drying chamber is ma...

Embodiment 2

[0017] Before drying starts, first turn on the refrigeration system to reduce the temperature of the circulating water of the cooling device to about 0°C, turn on the heater I8 to raise the temperature of the drying chamber 12 to 45°C, turn on the heater II17 to raise the temperature of the desiccant reaction chamber 18 To 30 ℃; Tilapia fillet is cut into 30mm * 30mm * 7mm (thick), it is placed on the stainless steel wire mesh 24 of drying chamber 12, then seals drying chamber 12; Open valve I2, valve II7, close valve III11 , Valve VI16, feed dry carbon dioxide into the drying chamber 12, open the valve V14, discharge the residual air in the drying chamber 12 and then close the valve V14; then the pressure of the drying chamber 12 is raised to 25MPa by the high-pressure pump 5; open the valve VI16 , valve VIII21, close valve VII20, and the drying process begins. During the drying process, the constant pressure of the drying chamber is maintained at 25 MPa by the high-pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com