Processing method of normal-temperature preserved instant bloated fish food

A processing method and technology of smoked fish, applied in food preparation, food science, application, etc., can solve problems affecting product quality and safety, fish fat oxidation, and large edible limitations, so as to shorten the dehydration and drying time and extend the shelf life , the effect of convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

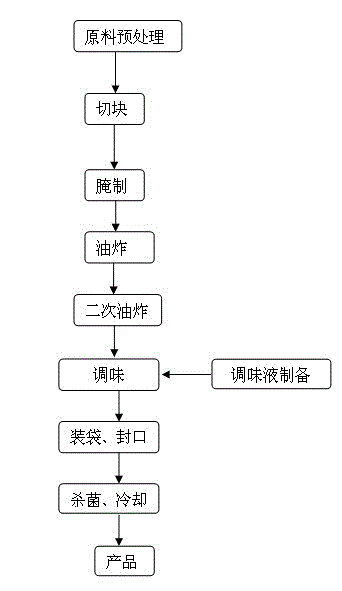

Image

Examples

Embodiment 1

[0024] The fresh and live fish are slaughtered, descaled, gutted, head and tail removed, washed, drained, and cut into fish pieces of appropriate size, weighing about 70 grams, and marinated in the pickling solution for 1.5 h. The marinating temperature is controlled below 30℃. The marinating liquid formula is 2% salt, 2% white vinegar, 0.5% monosodium glutamate, 3% cooking wine, adding water to make up 100%; add water to make up 100% of the marinated fish. Fry in 120-140℃ oil for 2-3min, control the weight loss rate at 20%-25%; put it in 160-190℃ oil for the second time deep frying, time 0.5-2 min, fry until the surface is golden, control the weight loss rate 10%-15%, drain the oil and set aside. The seasoning liquid ingredients are per 1kg water, 1.5g star anise, 1.3g cinnamon, 1.4g fennel, 2g ginger, 100g sugar, 1g soy sauce, boil for 1-2 hours, filter and add 5g edible vinegar, then add water to quantify the seasoning liquid After reaching 500g, set aside. Add the fried f...

Embodiment 2

[0026] The fresh and live fish are slaughtered, descaled, gutted, head and tail removed, washed, drained, and cut into pieces of appropriate size, weighing about 70 grams, and marinated in the pickling solution for 0.5 h. The marinating temperature is controlled below 30℃. The marinating liquid formula is 4% salt, 5% white vinegar, 1.0% monosodium glutamate, 5% cooking wine, adding water to make up 100%; the seasoning liquid ingredients are added per 1kg Water, 1.5g star anise, 1.3g cinnamon, 1.4g fennel, 2g ginger, 125g sugar, 2g soy sauce, cook for 1-2 hours, filter and add 8g edible vinegar, then add water to quantify the seasoning liquid to 500g for use. Add the fried fish cubes to the seasoning liquid according to the mass ratio of 1:1 and add a certain amount of fried fish, soak for about 30 minutes. Put the seasoned fish pieces into a packaging bag, each bag contains one piece, each bag has a net weight of about 50 grams, vacuum-sealed under a vacuum of 0.08-0.09MPa, and...

Embodiment 3

[0028] The fresh and live fish are slaughtered, descaled, gutted, headed, tailed, washed, drained, and cut into fish pieces of appropriate size, weighing about 70 grams, and marinated in the pickling solution for 1.0 h. The marinating temperature is controlled below 30℃. The marinating liquid formula is 3% salt, 4% white vinegar, 0.8% monosodium glutamate, 2% cooking wine, and water to make up 100%; add water to make up 100% of the marinated fish. Fry in 120-140℃ oil for 2-3min, control the weight loss rate at 20%-25%; put it in 160-190℃ oil for the second time deep frying, time 0.5-2 min, fry until the surface is golden, control the weight loss rate 10%-15%, drain the oil and set aside. The seasoning liquid ingredients are per 1kg water, 1.5g star anise, 1.3g cinnamon, 1.4g fennel, 2g ginger, 150g sugar, 3g soy sauce, boil for 1-2 hours, filter and add 10g edible vinegar, then add water to quantify the seasoning liquid After reaching 500g, set aside. According to the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com