Drying equipment with convenient discharging function for agricultural grain processing

A drying equipment and a convenient technology, applied in the field of agricultural machinery, can solve the problems of insufficient drying efficiency in grain collection, short contact time between grain and hot air, and increase farmers' work intensity, so as to improve the quality of grain products and improve the The material is convenient and fast, and the effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

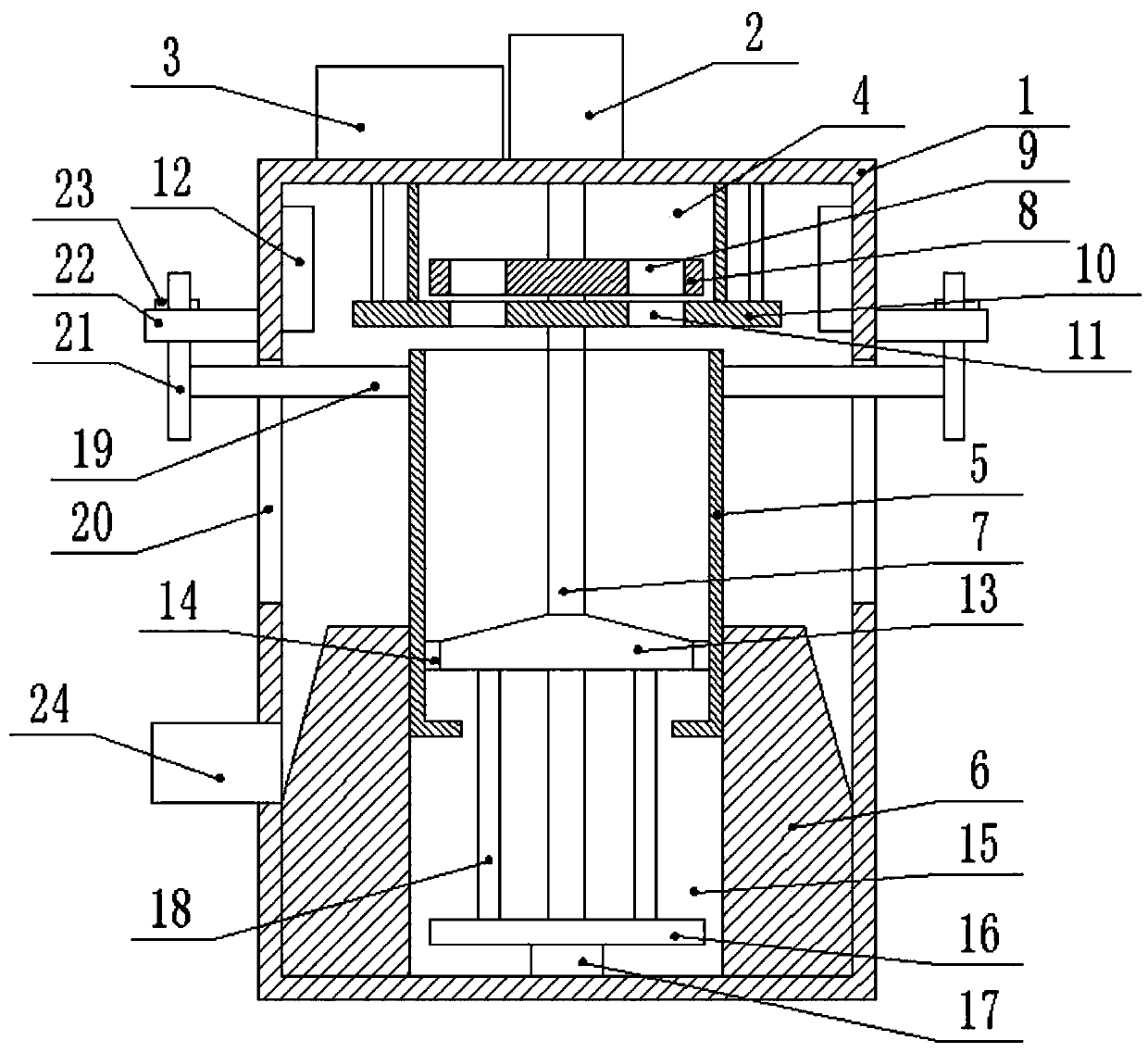

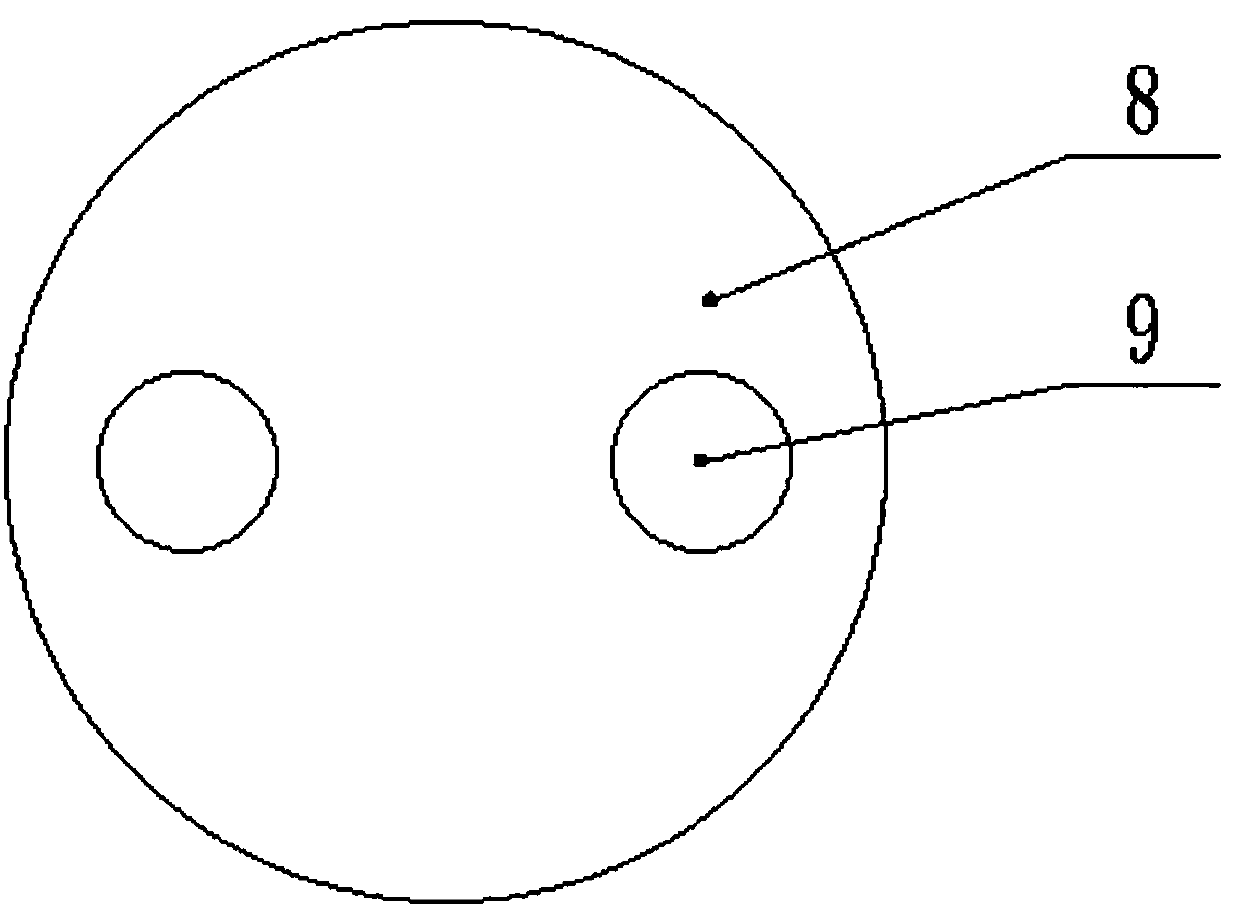

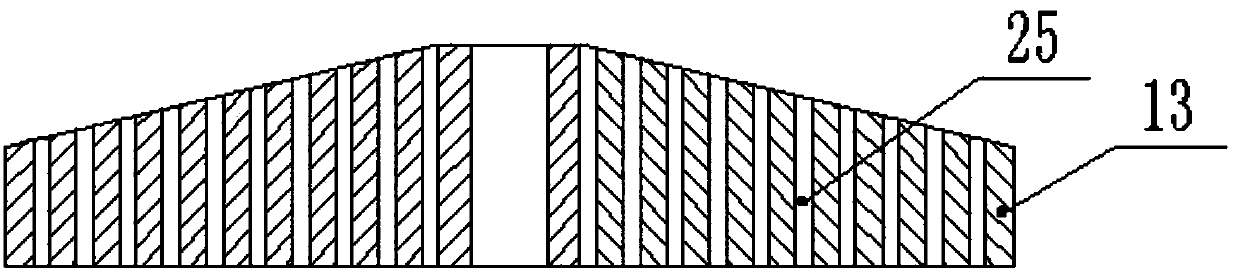

[0018] Please refer to the figure, in the embodiment of the present invention, a kind of drying equipment for agricultural grain processing with convenient discharge includes a housing 1, a motor 2, a feeding hopper 3 and a drying cylinder 5; the motor 2 is fixed on the housing 1 The top of the top, the output shaft of the motor 2 extends vertically downwards into the housing 1, and a vertical transmission shaft 7 is fixedly connected to the lower end of the output shaft of the motor 2, and the transmission shaft 7 is located on the central axis of the housing 1. The lower end of the shaft 7 is fixedly connected with a horizontal support plate 16, the lower central shaft of the support plate 16 is fixed with a rotating shaft 17, and the lower end of the rotating shaft 17 is installed on the bottom of the housing 1 through a bearing; the transmission shaft 7 is arranged from top to bottom It passes through the storage box 4 and the drying cylinder 5 in turn.

[0019] Described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com