Energy-saving food drying baking room

A food drying and energy-saving technology, applied in the fields of food preservation, food processing, food science, etc., can solve the problems of high energy consumption and high pollutant discharge, and achieve the effect of reducing energy consumption, reducing emissions and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

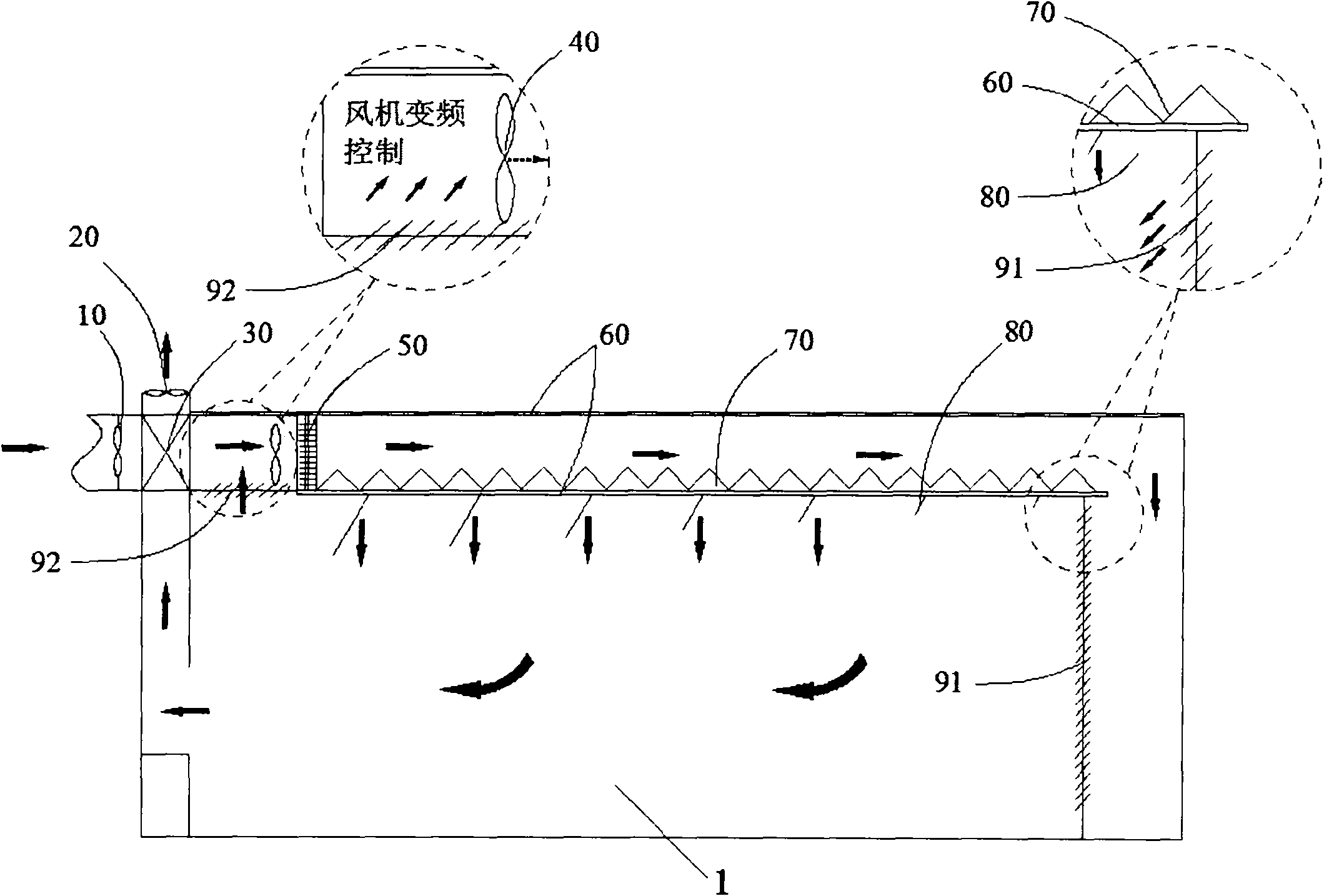

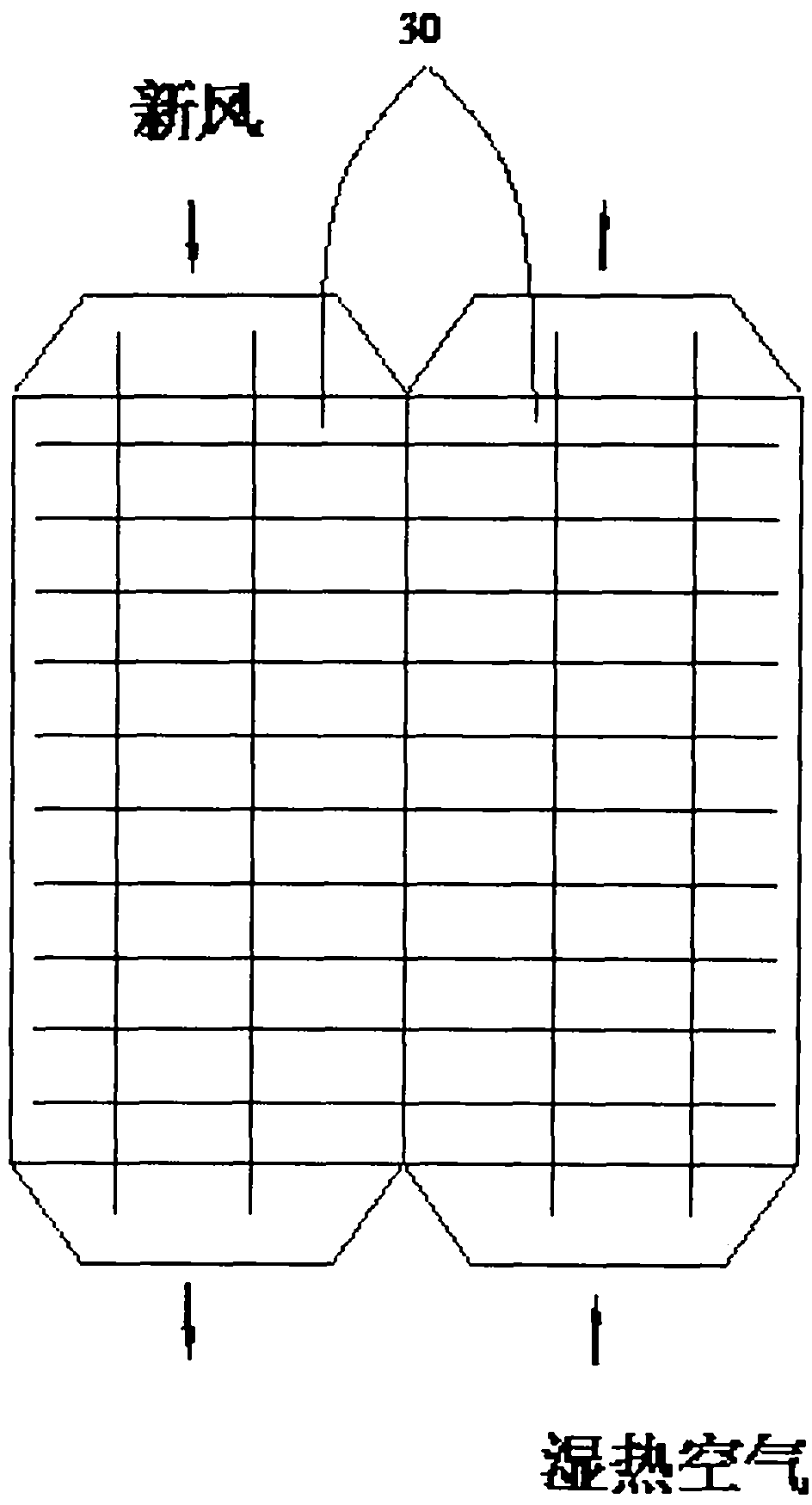

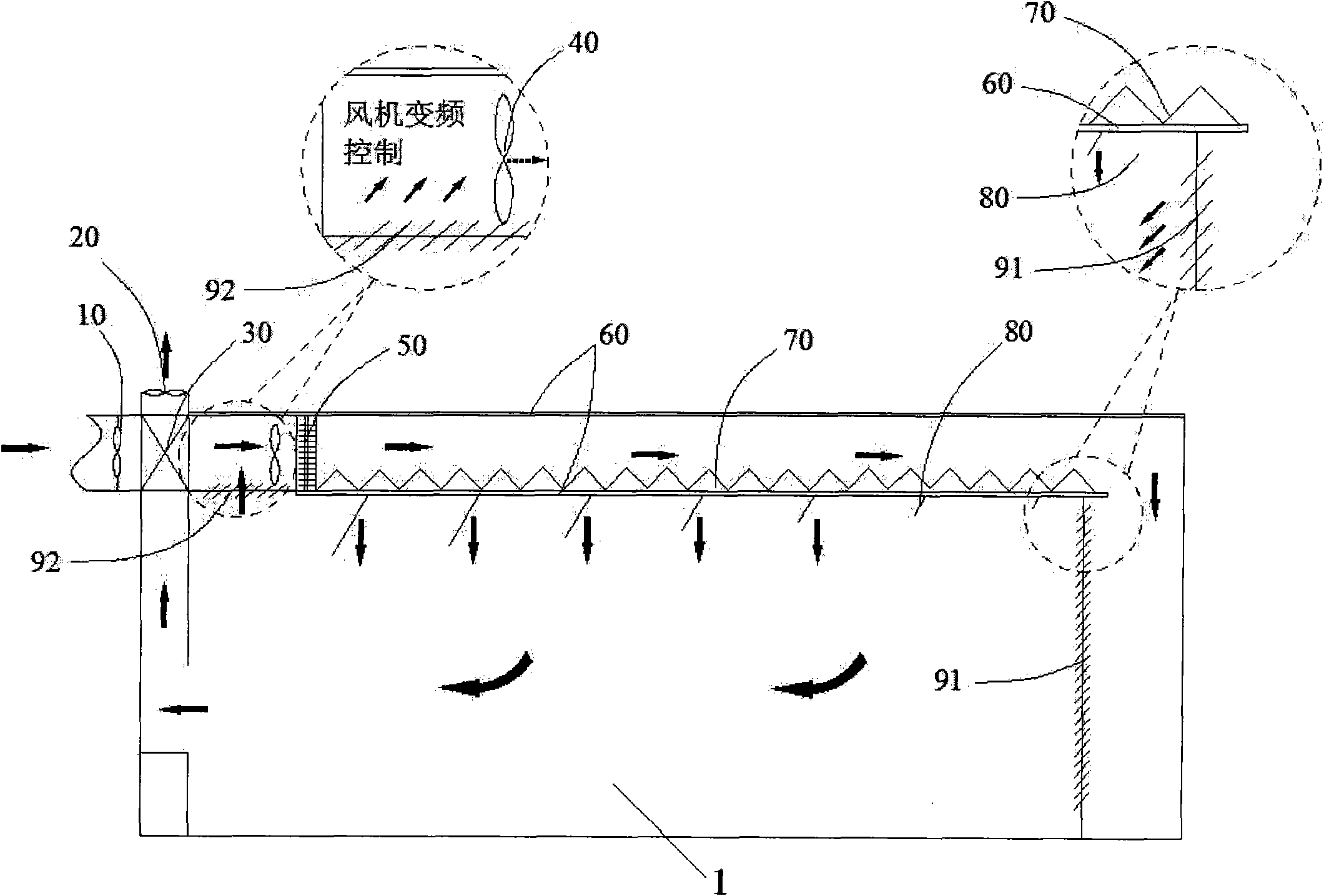

[0022] see figure 1 and 2 shown. The energy-saving food drying baking room of the present invention mainly includes: a baking room 1, an air inlet and an air outlet arranged on the baking room 1, a first air exchange door 10 is installed at the air inlet, and a first ventilation door 10 is installed at the air outlet. Two air exchange valves 20; a heat pipe heat exchanger 30 is installed between the air outlet and the air inlet to recycle waste heat; a frequency conversion circulating fan 40 is installed between the glass top layer and the glass ceiling of the dry baking room, and the air volume can be adjusted through frequency conversion control, which can Effectively improve the eddy current phenomenon in the baking room, make the flow field, temperature field and humidity field of the whole baking room uniform, and reduce energy loss;

[0023] A heater 50 is installed in front of the circulating fan 40 for heating in the drying room; a transparent glass layer 60 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com