Constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device for conditioning fruits and vegetables, and application of constant-pressure ultrasound atomizing-low-frequency microwave pulse spouting and drying device

A low-frequency microwave, pulse jet technology, used in applications, food processing, food science, etc., to achieve high-efficiency, energy-saving, high-quality drying, improve drying efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

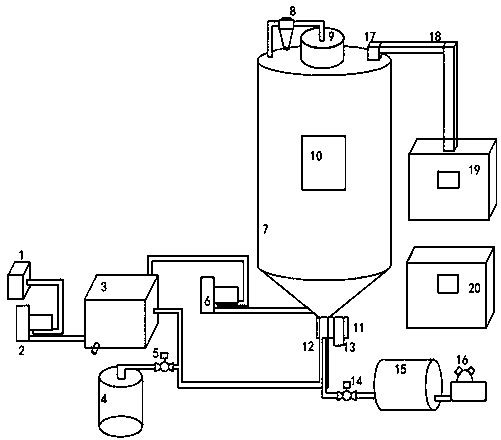

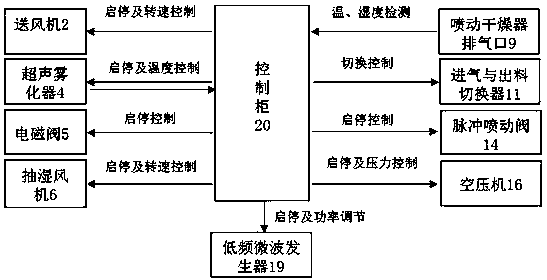

[0035] Such as figure 1 Shown: a normal-pressure ultrasonic atomization-low-frequency microwave pulse spray drying device for conditioning fruits and vegetables, including a suction filter 1, a blower 2, a heat exchanger 3, an ultrasonic atomizer 4, a dehumidifying fan 6, a spray Bed dryer 7, compressed air storage tank 15, air compressor 16, low frequency microwave source 19 and control cabinet 20;

[0036] The suction filter 1 is connected to the air blower 2, the air blower 2 is connected to the heat exchanger 3, and the heat exchanger 3 and the ultrasonic atomizer 4 are connected to the bottom of the spouted bed dryer 7 through the inlet pipe; The dehumidifier 6 is connected to the heat exchanger 3, the bottom of the spouted bed dryer 7 is also connected to the compressed air storage tank 15, and the compressed air storage tank 15 is connected to the air compressor 16; the upper end of the spouted bed dryer 7 is connected to the low frequency The microwave source 19 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com