Food drying method

A food drying and drying chamber technology, which is used in food preservation, food processing, and dry preservation of meat/fish, etc. It can solve the problems of strong electromagnetic radiation, large investment, and complex equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

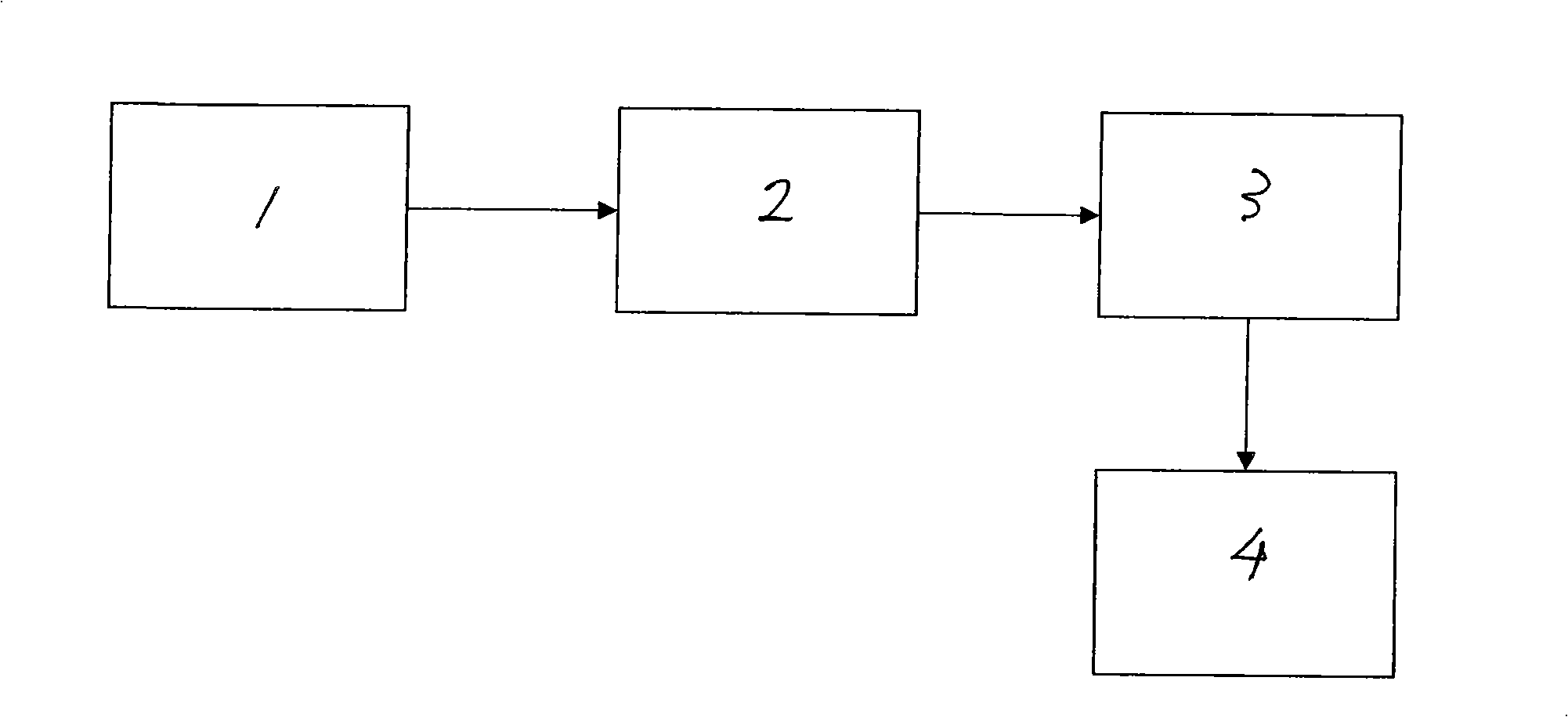

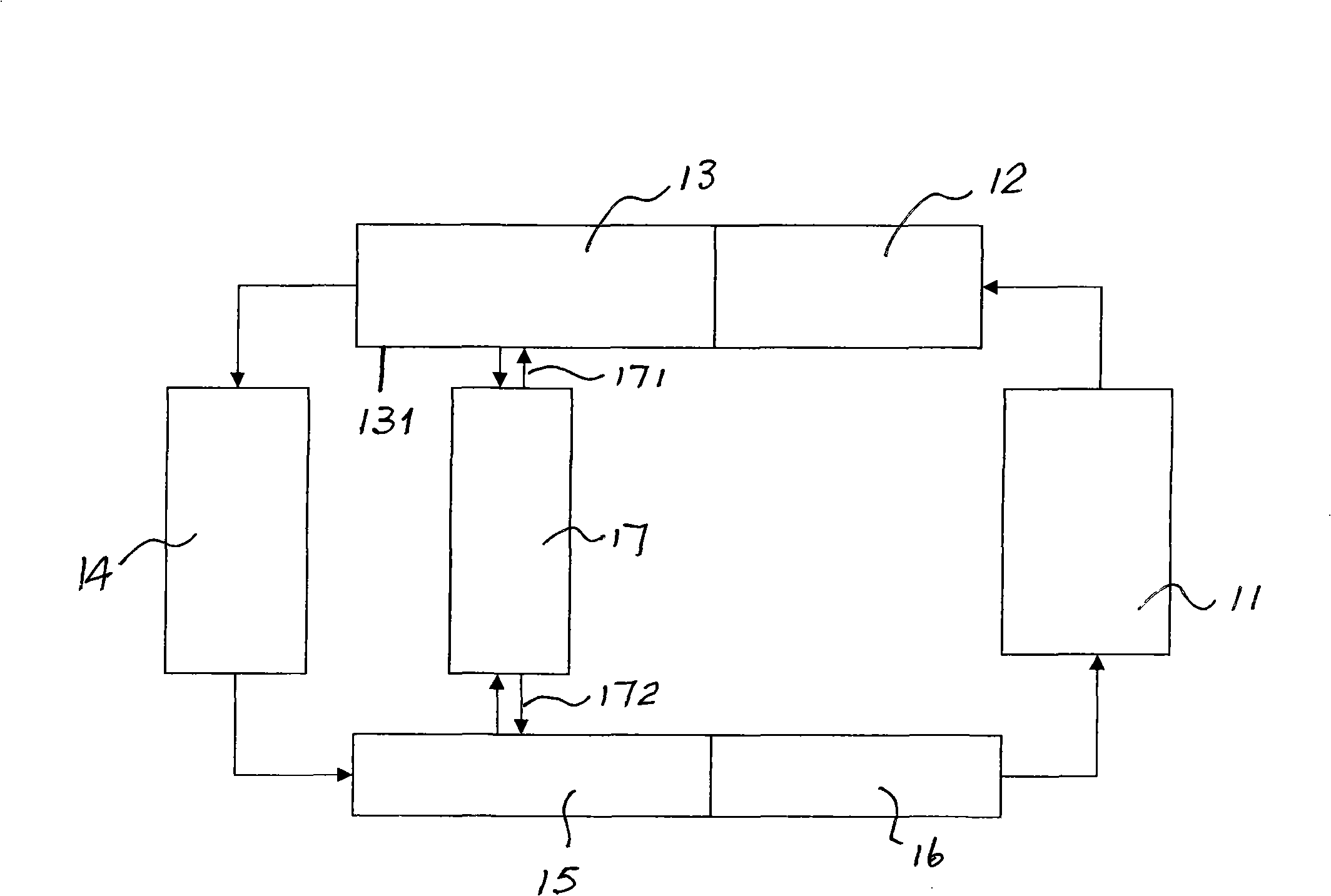

Method used

Image

Examples

Embodiment 1

[0031] A method for drying rosebuds, which mainly adopts the following steps:

[0032] Step 1: Establish an interoperable closed system consisting of a drying room, an air filter, an air dehumidifier, a fan, a heater and pipelines, and place 48 kg of rosebuds in the drying room;

[0033] Step 2: Maintain the air pressure in the closed system between 95kPa and 100kPa, start the air filter in the drying room, turn on the fan, the wind speed is 0.3-1.2 m / s, and the air in the closed system passes through the air filter , become dry and clean;

[0034] Step 3: Turn on the air dehumidifier, control the temperature between 3°C and 7°C, dehumidify the air, and discharge the condensed water;

[0035] Step 4: Turn on the heater in the drying room to heat the air that has been filtered, dried and dehumidified. The temperature of the air heated in the drying room is between 65-85°C. The air enters the drying room under the strong air blowing effect of the fan to further remove the mois...

Embodiment 2

[0037] A kind of drying method of apple, it mainly adopts following steps:

[0038] First, slice the apple,

[0039] Step 1: Establish an interoperable airtight system consisting of a drying room, an air filter, an air dehumidifier, a fan, a heater and pipelines, and place 9.6 kg of sliced apples in the drying room;

[0040] Step 2: Maintain the air pressure in the closed system between 95kPa and 100kPa, start the air filter in the drying room, turn on the fan, the wind speed is 0.6-1.8 m / s, and the air in the closed system passes through the air filter , become dry and clean;

[0041] Step 3: Turn on the air dehumidifier, control the temperature between 1°C and 5°C, dehumidify the air, and discharge the condensed water;

[0042] Step 4: Turn on the heater in the drying room to heat the air that has been filtered, dried and dehumidified. The temperature of the air heated in the drying room is between 65-90 ° C. The temperature is raised for 1 hour, and the heated air is fi...

Embodiment 3

[0044] A method for drying vegetables for instant noodles is characterized in that it mainly adopts the following steps:

[0045] First, diced instant noodles with vegetables, such as carrots, green onions, and ginger,

[0046]Step 1: Establish an interoperable closed system consisting of a drying room, an air filter, an air dehumidifier, a fan, a heater and pipelines, and place 5 kg of vegetables for instant noodles in the drying room;

[0047] Step 2: Maintain the air pressure in the closed system between 95kPa and 100kPa, start the air filter in the drying room, turn on the fan, the wind speed is 0.6-1.2 m / s, and the air in the closed system passes through the air filter , become dry and clean;

[0048] Step 3: Turn on the air dehumidifier, control the temperature between 0°C and 5°C, dehumidify the air, and discharge the condensed water;

[0049] Step 4: Turn on the heater in the drying room to heat the air that has been filtered, dried and dehumidified. The temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com