Downhole ultrasonic well cleaning device

an ultrasonic and well cleaning technology, applied in the direction of cleaning process and apparatus, cleaning using liquids, borehole/well accessories, etc., can solve the problems of insufficient external electrical power, inconvenient operation, and inability to deliver external electrical power as required in the prior art, so as to improve the efficiency of well cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Piezoelectric materials transform energy from mechanical to electrical and vice-versa. Piezoelectric materials produce an electric field when exposed to a change in dimension caused by an imposed mechanical force (mechanical to electrical conversion) and conversely, an applied electric field will produce a mechanical stress (electrical to mechanical conversion). These materials can be used for sensing purposes, including actuator and sensor applications.

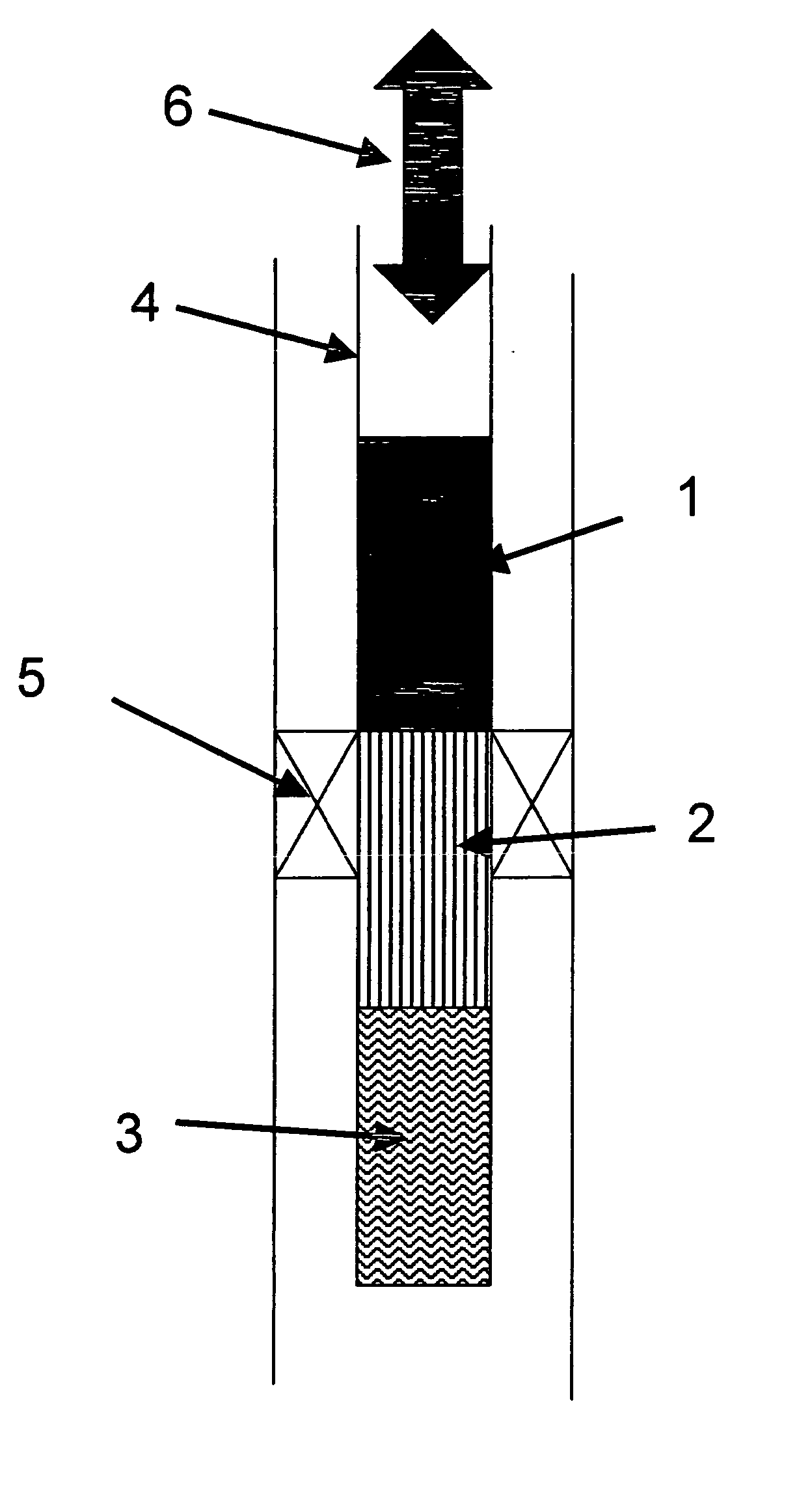

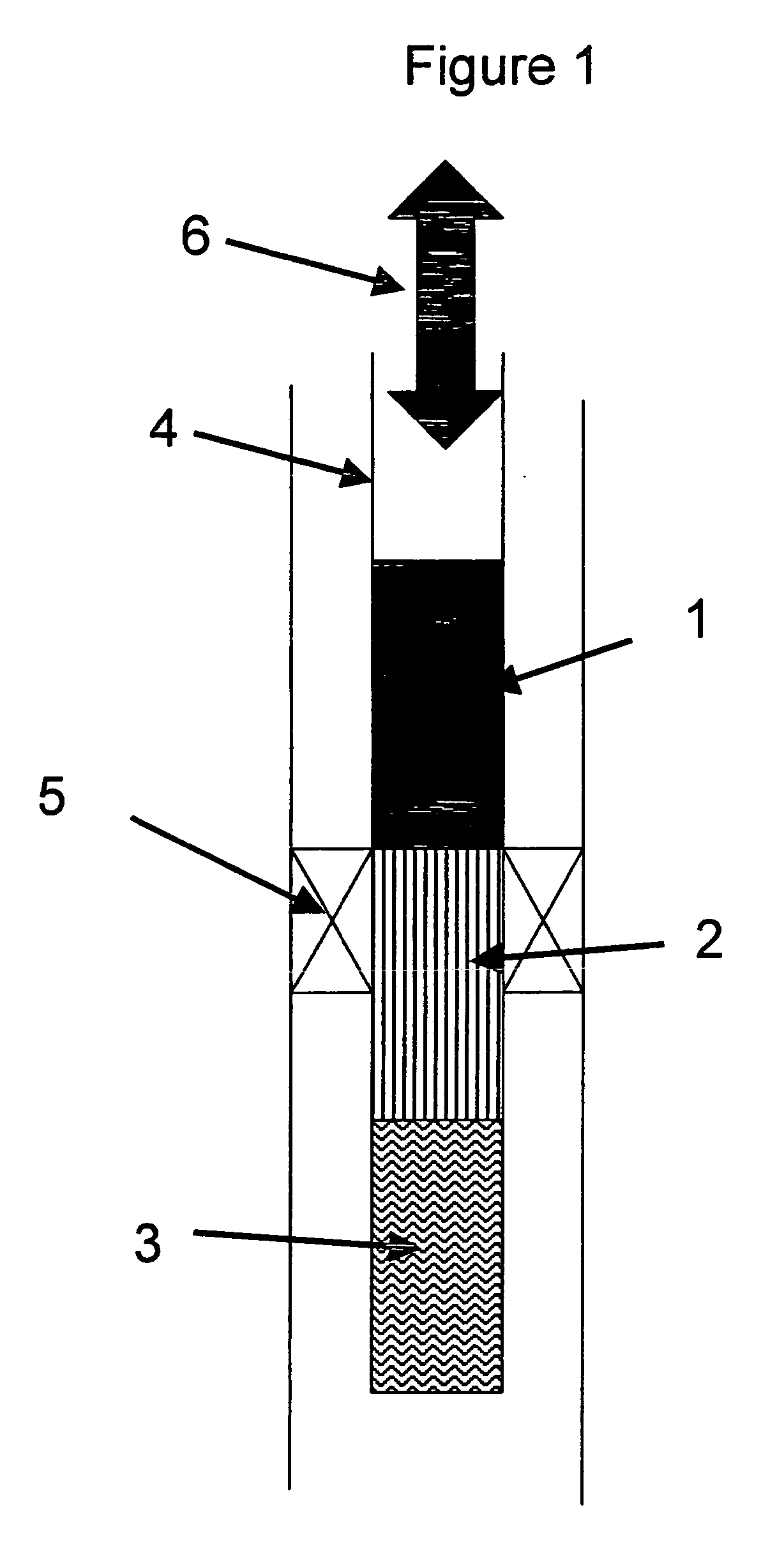

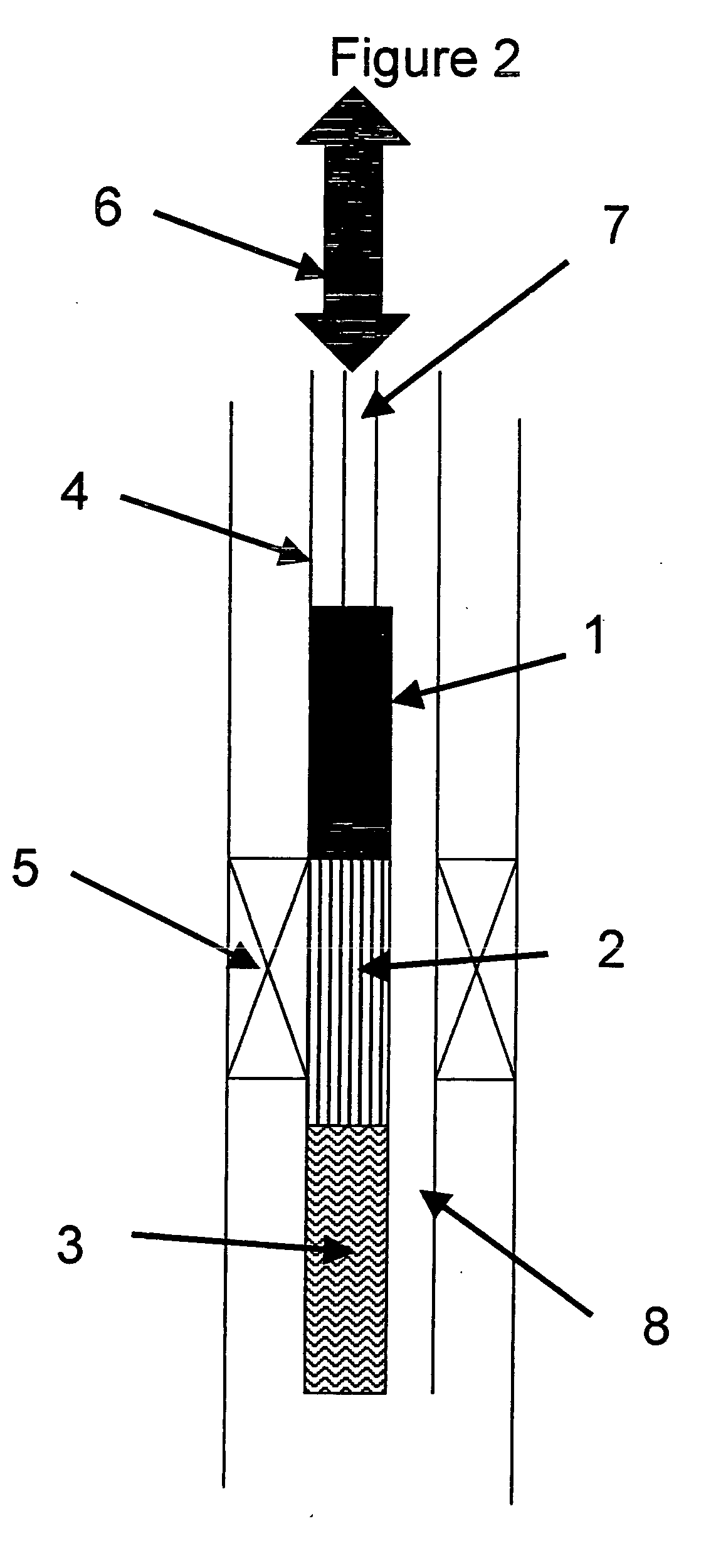

[0025] In the present invention a downhole ultrasonic well cleaning device is powered by an apparatus that converts mechanical force into electrical energy, preferably a piezoelectric generator. Both are installed or inserted within the completion equipment of any structure where the caking of particles may affect productivity. The preferred application is in cleaning wells and subterranean formations. The ultrasonic generator and piezoelectric element would be placed within the completion equipment (e.g. pipeline, tubing, pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com