Method for extracting aluminum oxide from fly ash based on ammonium sulfate activation process

A technology of fly ash and ammonium sulfate, applied in alumina/aluminum hydroxide and other directions, can solve the problems of large equipment investment, long process chain, material melting and sticking to the wall, etc., so as to improve the extraction rate and purity, and solve the problem of melting and sticking. , the effect of shortening the process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

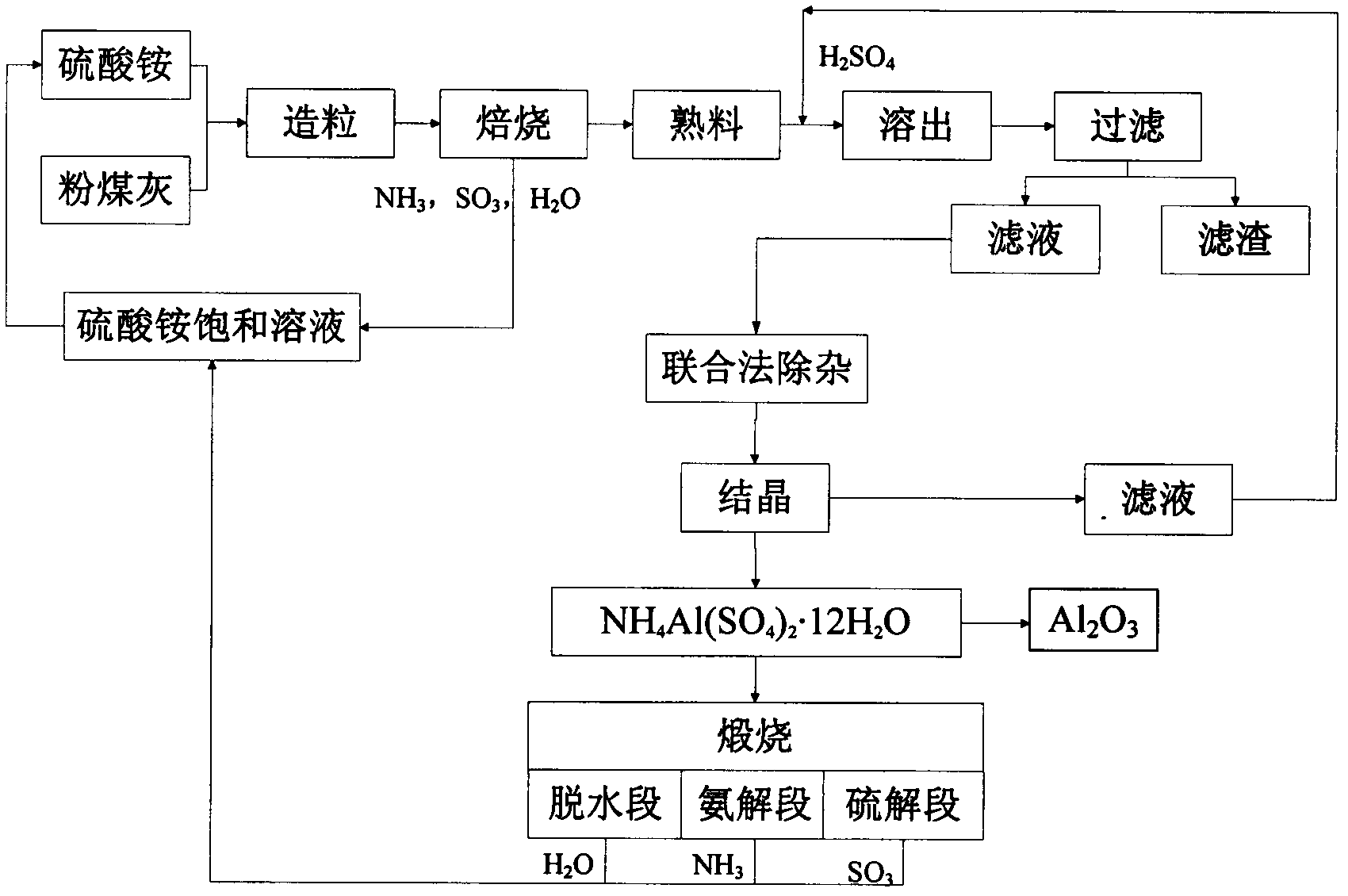

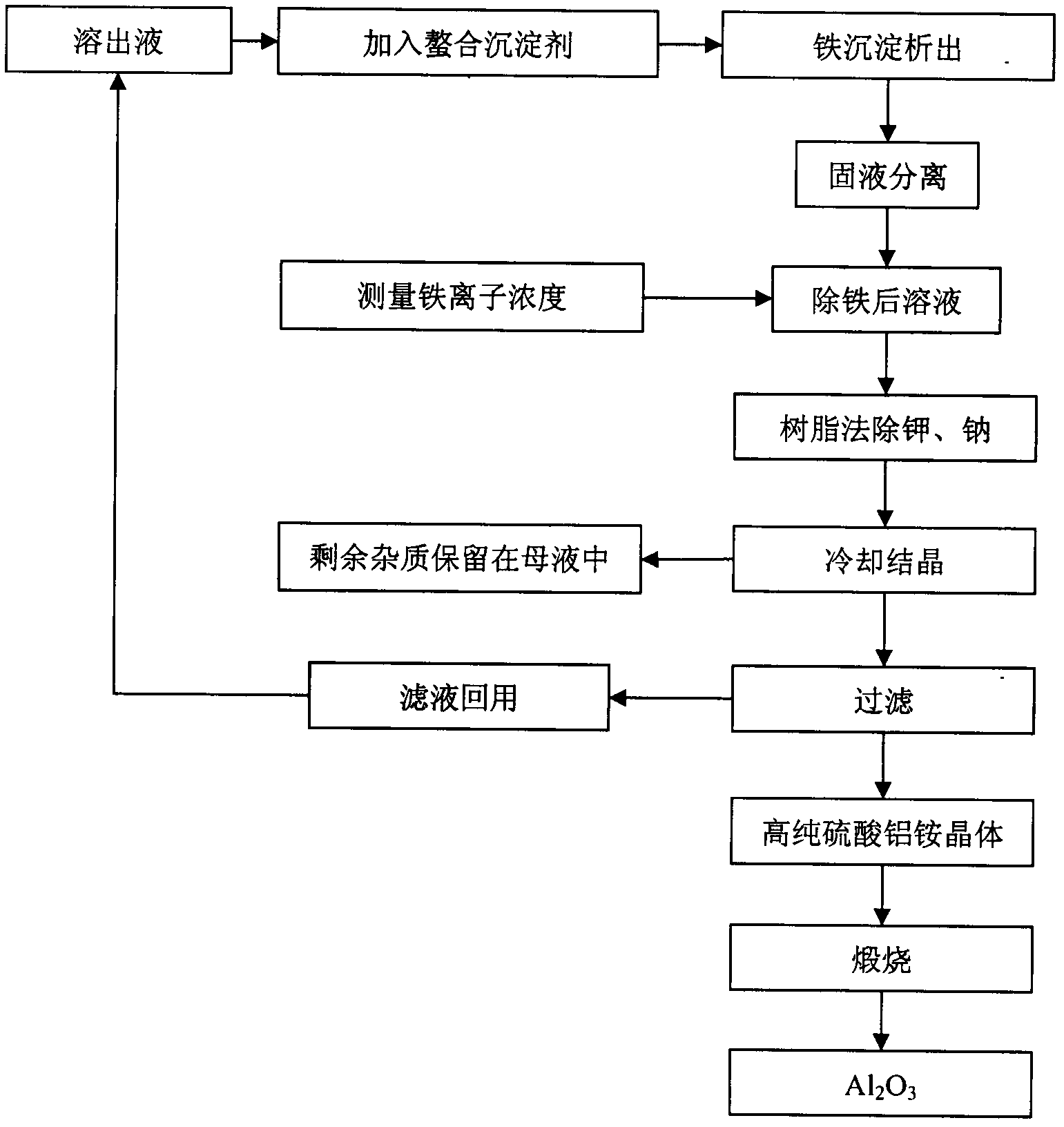

[0062] (1) Fly ash and ammonium sulfate (NH 4 ) 2 SO 4 Mixing granulation, see figure 1

[0063] 2130Kg fly ash (containing Al 2 o 3 48.2%) and 2640Kg (NH 4 ) 2 SO 4 (the molar ratio is 1:2), mix evenly, grind to reach the specified particle size (20 micron particles account for 80%), add 600Kg of water, adopt industrial drum or drum granulator to uniformly granulate, and mix the particles with spherical shape The particle size is 5mm in diameter, and more than 80% of the qualified particles are qualified. Obtain 5360Kg of granulated finished product.

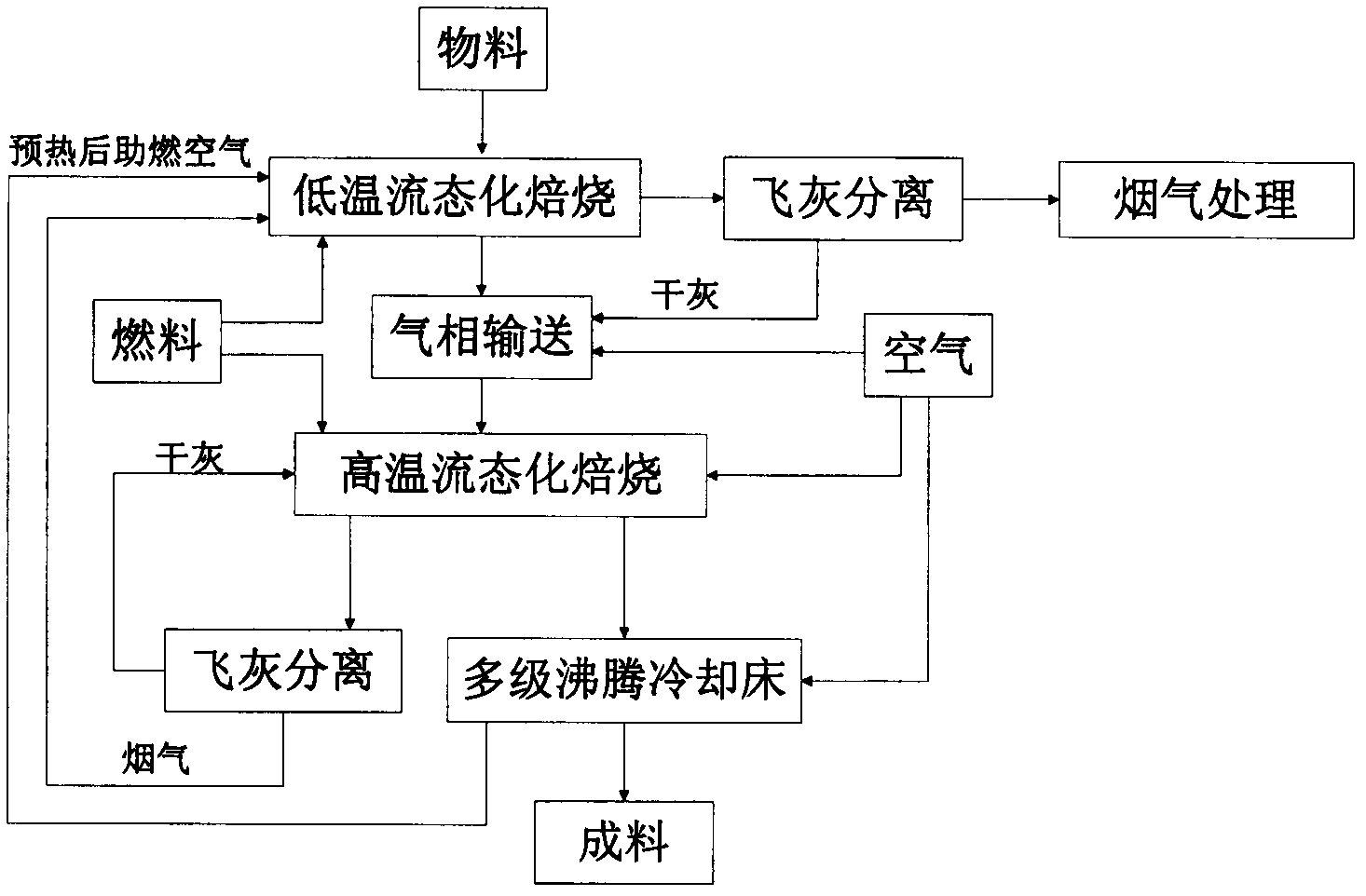

[0064] (2) Roast the particles in a two-stage fluidized roasting system, see figure 2

[0065] The granulated finished product enters the low-temperature fluidized roasting system through the silo and special material feeding device, and undergoes low-temperature roasting to remove all the moisture on the surface of the granules.

[0066] The dehydrated powder coming out of the low-temperature roasting fluidized be...

Embodiment 2

[0074] (1) Fly ash and ammonium sulfate (NH 4 ) 2 SO 4 Mixing granulation, see figure 1

[0075] 2130Kg fly ash (containing Al 2 o 3 48.2%) and 6600Kg (NH 4 ) 2 SO 4 (the molar ratio is 1:5), mix evenly, grind to reach the specified particle size (20 micron particles account for 80%), add 1500Kg of water, use industrial drum or drum granulator to uniformly granulate, and mix the particles with spherical shape The particle size is 3mm in diameter, and more than 80% of the qualified particles are qualified. Obtain granulated finished product 10210Kg.

[0076] (2) Roast the particles in a two-stage fluidized roasting system, see figure 2

[0077] The granulated finished product enters the low-temperature fluidized roasting system through the silo and special material feeding device, and undergoes low-temperature roasting to remove all the moisture on the surface of the granules.

[0078] The dehydrated powder coming out of the low-temperature roasting fluidized bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com