Biologic organic bamboo charcoal fertilizer and production method thereof

A technology of bio-organic fertilizer and production method, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of increasing the incidence of soil diseases and insect pests and the accumulation of heavy metals, and achieve the effect of complete nutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

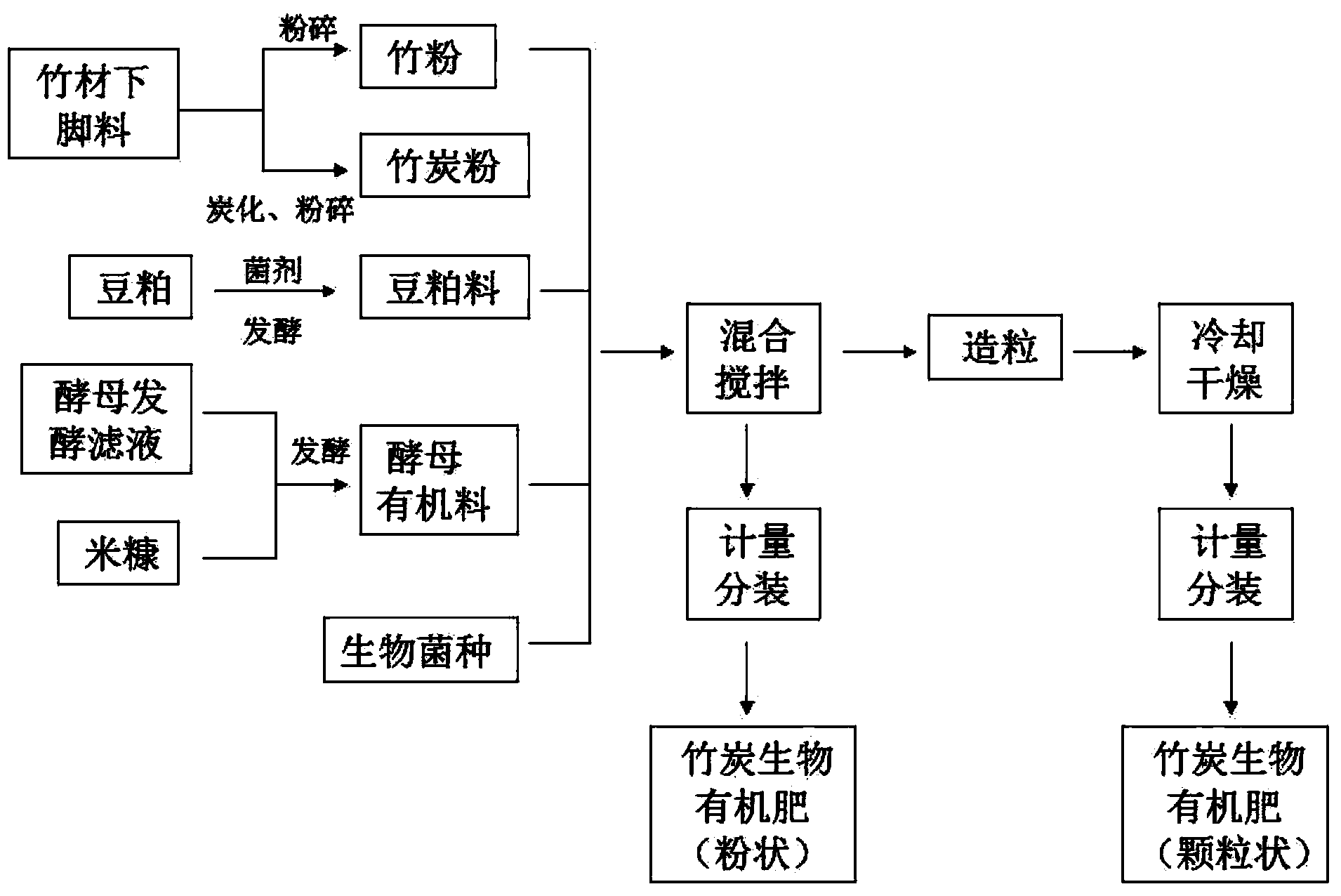

Method used

Image

Examples

Embodiment 1

[0045] Cut the selected suitable bamboo or bamboo waste, dry it naturally or manually, carbonize it at a high temperature, cool it and then pulverize it with a pulverizer to obtain bamboo charcoal powder with a fineness of 80-100 mesh and a water content of 9% or less. The selected suitable bamboo material or bamboo waste is crushed and cut, dried naturally or manually, and preliminarily crushed by a grinder, and then ground into powder by a grinder to obtain bamboo powder with a fineness of 80-100 mesh and a water content of less than or equal to 6%. The biological strain is Bacillus subtilis.

[0046] The obtained bamboo charcoal powder and bamboo powder are accurately compounded with soybean meal, yeast organic material, biological strains and binder according to the raw material ratio in Table 1. It is fully mixed by a mixer and granulated by a granulator to prepare a granular bamboo charcoal biological organic fertilizer.

[0047] Table 1 Production formula of bamboo charcoal...

Embodiment 2

[0050] Cut the selected suitable bamboo or bamboo waste, dry it naturally or manually, carbonize it at a high temperature, cool it and then pulverize it with a pulverizer to obtain bamboo charcoal powder with a fineness of 80-100 mesh and a water content of 9% or less. The selected suitable bamboo material or bamboo waste is crushed and cut, dried naturally or manually, and preliminarily crushed by a grinder, and then ground into powder by a grinder to obtain bamboo powder with a fineness of 80-100 mesh and a water content of less than or equal to 6%. The biological strain is Bacillus Laterosporus.

[0051] The obtained bamboo charcoal powder and bamboo powder are accurately blended with soybean meal, yeast organic material, and biological strains according to the raw material ratio in Table 2. The powdered bamboo charcoal bio-organic fertilizer is prepared by stirring and mixing thoroughly by a mixer.

[0052] Table 2 Production formula of bamboo charcoal bio-organic fertilizer

...

Embodiment 3

[0055] Except for the following processes, the others are the same as in Example 1. The biological strain is EM strain.

[0056] The bamboo charcoal powder and bamboo powder obtained in Example 1 were accurately compounded with soybean meal, yeast organic material, biological strains, and binder according to the raw material ratio in Table 3. It is fully mixed by a mixer and granulated by a granulator to prepare a granular bamboo charcoal biological organic fertilizer.

[0057] Table 3 Production formula of bamboo charcoal bio-organic fertilizer

[0058] Raw materials

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com