POSS/epoxy nanometer hybrid material and preparation method and application thereof

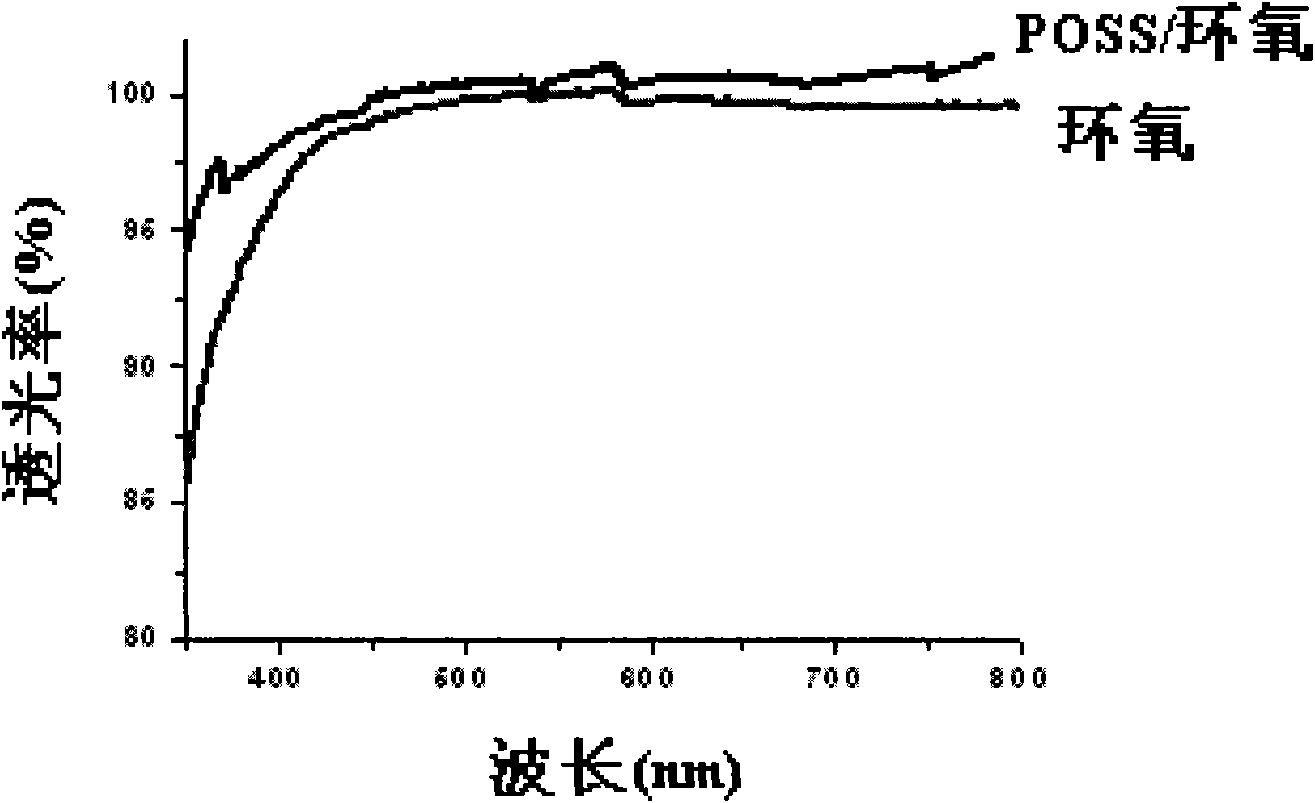

A hybrid material, epoxy nanotechnology, applied in epoxy resin coatings, epoxy resin glue, plastic/resin/wax insulators and other directions, can solve the problems of difficult solvent purification, poor mechanical properties, difficult reaction degree, etc. The production and preparation process is easy to control, the aging resistance is good, and the transparency is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] POSS / epoxy nano-hybrid material formula 1

[0052] Composition Amount (mass parts)

[0053] Hydrogenated bisphenol A epoxy resin 100

[0054] Diisobutyl-hexaepoxy POSS 10

[0055] Epoxysilane 10

[0056] Methylhexahydrophthalic anhydride 10

[0057] UV absorber 3

[0058] 1-cyanoethyl-2-ethyl-4-methylimidazole 2

[0059] In the reactor, add 50 parts of hydrogenated bisphenol A epoxy resin, 10 parts of diisobutyl-hexaepoxy POSS, stir for 5 hours, add 10 parts of epoxy silane, and continue stirring for 0.5 hours to obtain component A ,stand-by.

[0060] In the reactor, add 50 parts of hydrogenated bisphenol A epoxy resin, 10 parts of methyl hexahydrophthalic anhydride, stir for 2 hours, add component A, continue stirring for 1 hour, then add 3 parts of UV absorber, 2 parts of 1- Cyanoethyl-2-ethyl-4-methylimidazole curing accelerator, stirred for 1 hour to obtain POSS / epoxy nano-hybrid material.

[0061] The POSS / epoxy nano-hybrid material was heated at 100° C. fo...

Embodiment 2

[0063] POSS / epoxy nano-hybrid material formula 2

[0064] Composition Amount (mass parts)

[0065] Hydrogenated bisphenol A epoxy resin 100

[0066] Trihexyl-Pentaepoxide POSS 50

[0067] Tetraphenyl-tetraepoxy POSS 50

[0068] Epoxysilane 20

[0069] Tin octoate 2

[0070] In the reactor, add 50 parts of hydrogenated bisphenol A epoxy resin, 50 parts of trihexyl-pentaepoxy POSS, 50 parts of tetraphenyl-tetraepoxy POSS, stir for 6 hours, add 20 parts of epoxy silane , and continue to stir for 1 hour to obtain component A for use.

[0071] In the reactor, add 50 parts of hydrogenated bisphenol A epoxy resin and 2 parts of tin octoate, stir for 2 hours, add component A, and continue stirring for 5 hours to obtain POSS / epoxy nano-hybrid material.

[0072] The POSS / epoxy nano-hybrid material was heated at 150° C. for 2 hours, and cured in situ to obtain the POSS / epoxy nano-hybrid material.

Embodiment 3

[0074] POSS / epoxy nano-hybrid material formulation 3

[0075] Composition Amount (mass parts)

[0076] Cycloaliphatic epoxy resin 50

[0077] Hydrogenated bisphenol A epoxy resin 50

[0078] Octaepoxy POSS 100

[0079] Zirconium acetylacetonate 0.01

[0080] In the reactor, add 50 parts of cycloaliphatic epoxy resin and 100 parts of hydroxyl silicone oil, and stir for 8 hours to obtain component A, which is ready for use.

[0081] In the reactor, add 50 parts of hydrogenated bisphenol A epoxy resin and 0.01 part of zirconium acetylacetonate, and stir for 10 hours to obtain component B.

[0082] Mix the above-mentioned components A and B evenly, heat at 80° C. for 10 hours, and cure in situ to obtain a POSS / epoxy nano-hybrid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com