Addition-type organic silicon pouring sealant and preparation method thereof

A silicone potting and addition molding technology, applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems that affect the thermal conductivity and flame retardant properties of the potting glue, and the potting glue is difficult to disperse evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing the addition-type silicone potting compound described in the above technical solution, comprising the following steps:

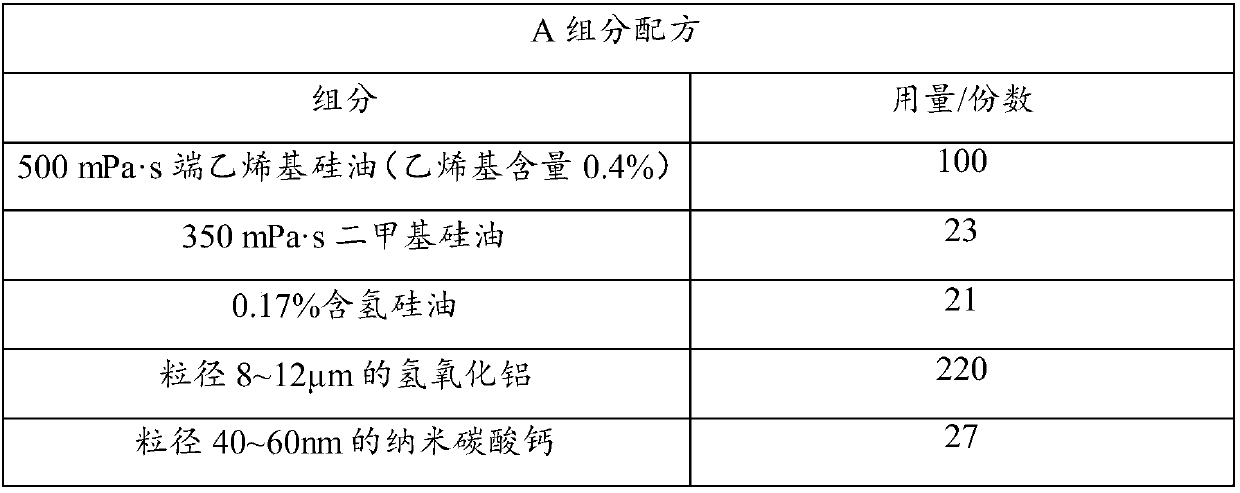

[0040] Mix 100 parts of vinyl silicone oil, 0-100 parts of dimethyl silicone oil, 1-50 parts of hydrogen-containing silicone oil, 20-250 parts of aluminum hydroxide, 0-200 parts of thermal conductive filler and 1-50 parts of nano-calcium carbonate, and heat to After dehydration at 100-150°C for 2-4 hours, vacuumize, lower the temperature to below 70°C, add 0.01-1 part of inhibitor, stir evenly, and obtain component A;

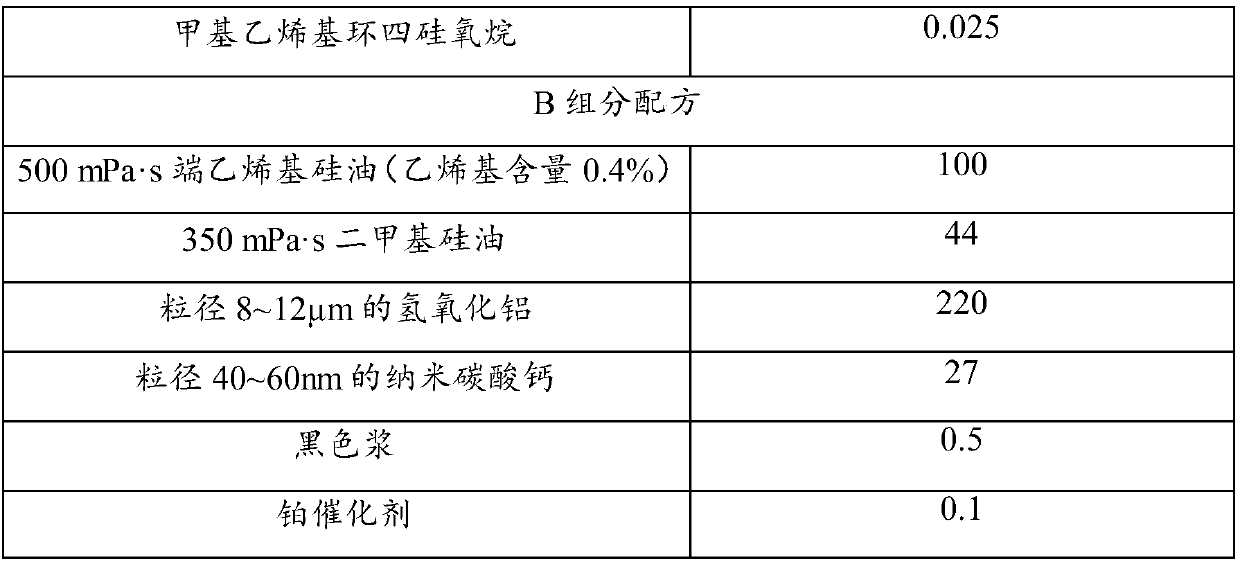

[0041] Mix 100 parts of vinyl silicone oil, 0-100 parts of dimethyl silicone oil, 20-250 parts of aluminum hydroxide, 0-200 parts of thermal conductive filler, 1-50 parts of nano-calcium carbonate and 0-10 parts of color paste, and heat to 100 After ~150°C, dehydrate for 2~4 hours, vacuumize, cool down to below 70°C, add 0.01~1 part of platinum catalyst, stir evenly, and obtain B co...

Embodiment 1

[0048] Component A: Put vinyl-terminated silicone oil, dimethyl silicone oil, hydrogen-containing silicone oil, aluminum hydroxide, and nano-calcium carbonate into the high-speed dispersing planetary machine according to the formula in Table 1 and stir, while heating to 100-150°C. Vacuum dehydration at -0.09~-0.1MPa for 2~4 hours, after dehydration, cool down to within 70°C, add inhibitor, stir evenly and discharge to obtain component A.

[0049] Component B: Put vinyl-terminated silicone oil, dimethyl silicone oil, aluminum hydroxide, nano-calcium carbonate, and color paste into the high-speed dispersing planetary machine according to the formula in Table 1 and stir, while heating to 100-150°C. Vacuum dehydration at -0.09~-0.1MPa for 2~4 hours, after dehydration, lower the temperature to less than 70°C, add platinum catalyst, stir evenly, and discharge to obtain component B.

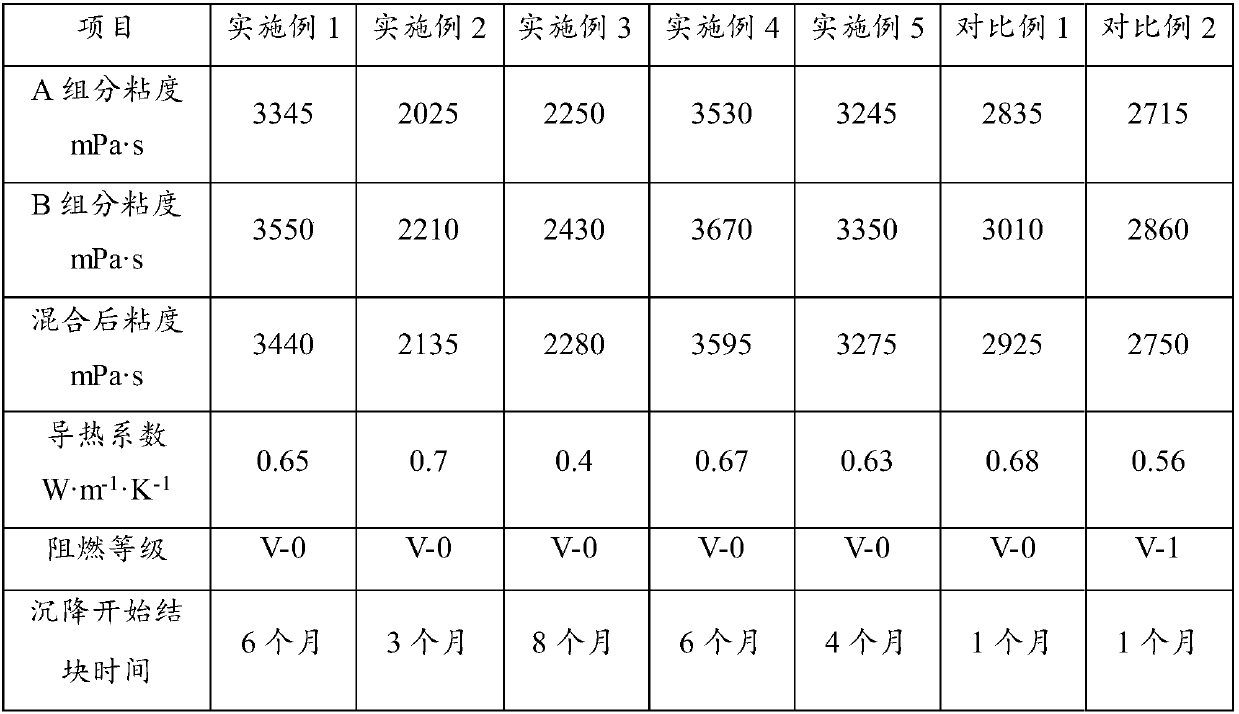

[0050] Test the viscosity of component A and component B, and take part of component A and component...

Embodiment 2

[0058] Component A: Put vinyl-terminated silicone oil, dimethyl silicone oil, hydrogen-containing silicone oil, aluminum hydroxide, and nano-calcium carbonate into the high-speed dispersing planetary machine according to the formula in Table 3 and stir, while heating to 100-150°C. Vacuum dehydration at -0.09~-0.1MPa for 2~4 hours, after dehydration, cool down to within 70°C, add inhibitor, stir evenly, and discharge to obtain component A.

[0059] Component B: Put vinyl-terminated silicone oil, dimethyl silicone oil, aluminum hydroxide, nano-calcium carbonate, and color paste into the high-speed dispersing planetary machine according to the formula in Table 3 and stir, while heating to 100-150°C, Vacuum dehydration at -0.09~-0.1MPa for 2~4 hours, after dehydration, lower the temperature to less than 70°C, add platinum catalyst, stir evenly, and discharge to obtain component B.

[0060] Test the viscosity of A and B components, and take part A and B glues according to the weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com