Heat-conducting sticking silica gel

A silica gel, bonding technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of excessive heat, insufficient adhesion, and overall performance degradation of the device, and achieve anti-precipitation. Good performance, improve adhesion, reduce the effect of poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

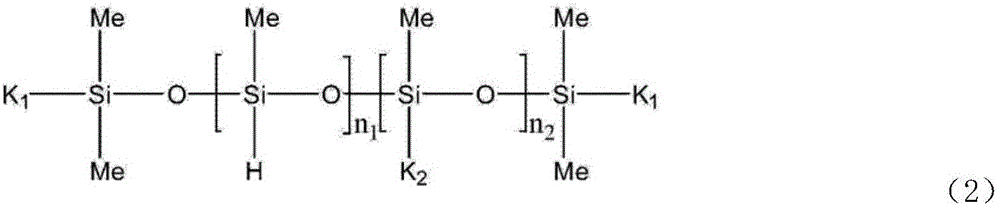

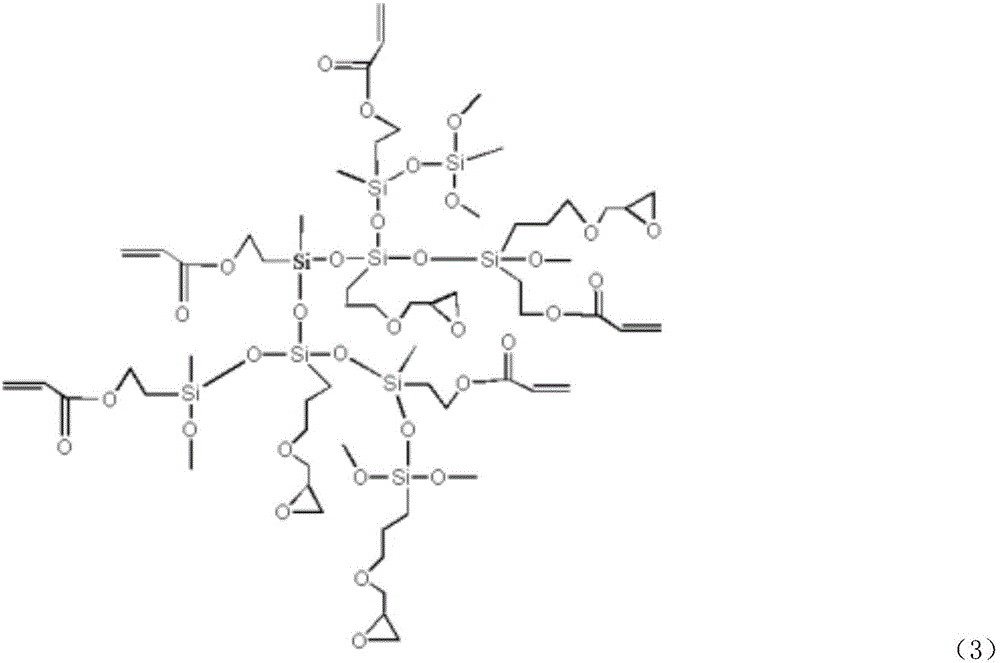

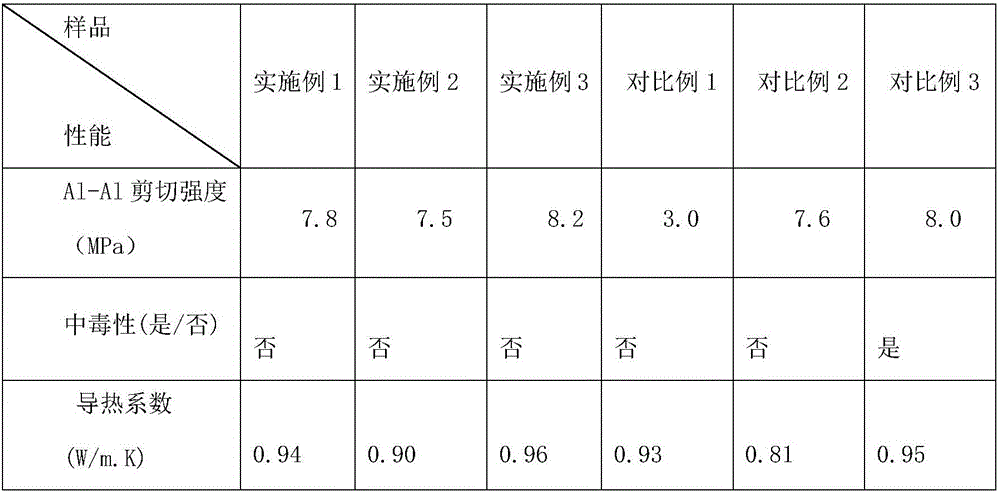

[0032] At 25 ° C, first weigh the viscosity of 20000mPa.s such as structural formula (1), where R 1 for-Vi, R 2 100g of -Me methyl vinyl silicone oil (vinyl content is 0.1wt%), viscosity is 5000mPa.s such as structural formula (1), wherein R 1 for-Vi, R 2 Be -Vi methyl vinyl silicone oil (vinyl content is 5wt%) 100g; Viscosity is 50g of diluent of 10mPa.s, joins in the 2L kneader, weighs the aluminum oxide powder 300g that particle diameter is 5 μm to join then In the kneader, stir at a low speed for 10 minutes, then continue to add 300 g of alumina powder with a particle size of 5 μm, stir at a low speed for 10 minutes, and finally add 140 g of alumina powder with a particle size of 5 μm; stir at a low speed for 10 minutes, increase the speed of the kneader , turn on the heating at the same time, set the temperature to 150°C, mix for 2 hours after reaching the temperature, and finally stir for 10 minutes under a vacuum of 0.8MPa, put the base material into a sealed barrel w...

Embodiment 2

[0035] At 25 ° C, first weigh the viscosity of 20000mPa.s such as structural formula (1), where R 1 for-Vi, R 2 Be -Vi methyl vinyl silicone oil (vinyl content is 0.1wt%) 150g, viscosity is 5000mPa.s such as structural formula (1), wherein R 1 for-Vi, R 2 Be-Me methyl vinyl silicone oil (vinyl content is 5wt%) 40g; Viscosity is 60g of diluent of 10mPa.s; Join in the 2L kneader, then take by weighing 300g of the aluminum oxide powder that particle diameter is 20 μm joins In the kneader, stir at a low speed for 10 minutes, then continue to add 300 g of alumina powder with a particle size of 20 μm, stir at a low speed for 10 minutes, and finally add 130 g of alumina powder with a particle size of 20 μm; stir at a low speed for 10 minutes, increase the speed of the kneader , turn on the heating at the same time, set the temperature to 150°C, mix for 2 hours after reaching the temperature, and finally stir for 10 minutes under a vacuum of 0.8MPa, put the base material into a seal...

Embodiment 3

[0038] At 25 ° C, first weigh the viscosity of 10000mPa.s such as structural formula (1), where R 1 for-Vi, R 2 190g of methyl vinyl silicone oil (vinyl content is 3wt%) for -Vi; 40g of diluent with a viscosity of 50mPa.s; join in a 2L kneader, and then weigh 250g of alumina powder with a particle diameter of 5 μm. Add 50g of alumina powder with a diameter of 20μm into the kneader, stir at low speed for 10 minutes, then continue to add 300g of alumina powder with a particle size of 20μm, stir at a low speed for 10 minutes, and finally add alumina powder with a particle size of 20μm 150g; Stir at low speed for 10 minutes, increase the speed of the kneader, turn on the heating at the same time, set the temperature to 150°C, mix for 2 hours after reaching the temperature, and finally stir for 10 minutes under a vacuum of 0.8MPa, and take the base material out to the sealed container while it is hot. In barrels, sealed and stored for later use;

[0039] Take by weighing above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com