Epoxy silsesquioxane/epoxy resin hybridized glue for packaging photoelectric devices and preparation method thereof

A technology of silsesquioxane and epoxy resin, applied in the direction of epoxy resin glue, chemical instruments and methods, electrical components, etc., can solve the problems of fatigue resistance, poor heat resistance and impact resistance, and difficulty in meeting the application requirements of optoelectronic devices , Low peel strength and other problems, achieve good electrical properties, improve bond strength and elongation at break, and reduce curing shrinkage

Inactive Publication Date: 2010-10-13

SHANGHAI UNIV

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional epoxy adhesives cannot meet the requirements of use after curing. After curing, there are shortcomings such as large internal stress, brittle texture, poor fatigue resistance, heat resistance, and impact resistance, as well as low peel strength and poor heat and humidity resistance. In addition, the high surface energy limits its application in some high-tech fields to a large extent, and silicone resin has attracted much attention due to its anti-rust, cold resistance, corrosion resistance, radiation resistance, ozone resistance and other properties, but the simple Silicone encapsulants have low bond strength, poor mechanical properties and high production costs, making it difficult to meet the application requirements of optoelectronic device encapsulation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Login to View More

Abstract

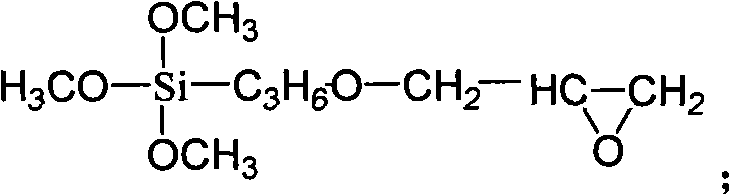

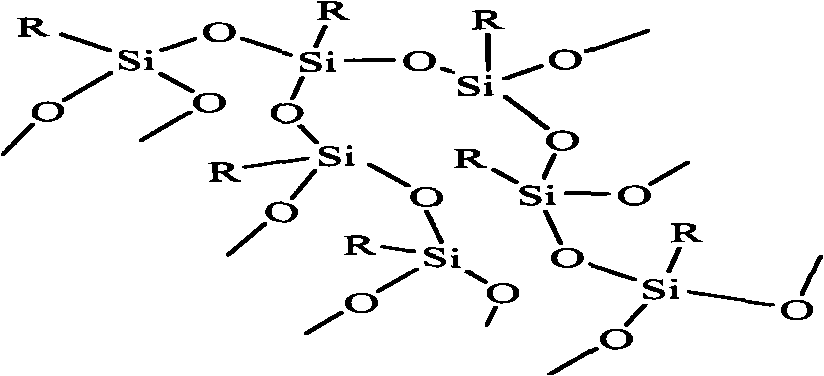

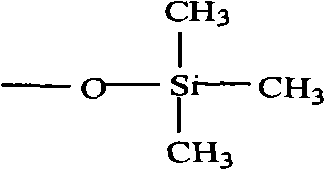

The invention relates to epoxy silsesquioxane / epoxy resin hybridized glue for packaging photoelectric devices and a preparation method thereof. The hybridized glue is prepared by mixing substrate resins, a curing agent and other components, wherein other components comprise the following materials in mass percentage: 12%-18% of modified epoxy silsesquioxane, 36%-42% of bisphenol A type epoxy resins, 30%-38% of polyamide, 5%-10% of N,N-diaminodiphenyl-methane and 0.5%-1.5% of triethylamine, and the structural formula of the modified epoxy silsesquioxane is shown in the specification, wherein Ris shown in the specification. The epoxy silsesquioxane synthesized in the method has high molecular weight, the maximum-average molecular weight reaches 1.1*10<6>, and the weight-average molecular weight reaches 1.21*10<6>. The prepared glue has the advantages of the epoxy silsesquioxane and the epoxy resins and has good heat resistance, cold resistance and corrosion resistance, high bonding performance, low curing contraction rate, good electrical performance, simple preparation process and easy operation of a preparation process, and excellent ultraviolet radiation resistance, chemical corrosion resistance and mechanical performance, wherein the electrical performance achieves the packaging requirements on the photoelectric devices.

Description

technical field The invention relates to a hybrid adhesive for photoelectric device packaging and a preparation method thereof, in particular to an epoxy silsesquioxane / epoxy resin hybrid adhesive for photoelectric device packaging and a preparation method thereof. Background technique With the development of electronic integration technology and printed circuit board technology, the density of electronic assembly has been greatly increased, electronic components have been reduced by tens of thousands of times, and the computing speed has become faster and faster. Under this high-frequency operating frequency, the working thermal environment of semiconductors moves rapidly to high temperature; at this time, the heat generated by electronic components accumulates and increases rapidly. The increase in temperature may be an important reason for the decline in the electrical insulation performance and mechanical properties of materials and the reduction in the life of electroni...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J163/02C09K3/10H01L31/0203

Inventor 贺英裴昌龙宋继中朱棣陈杰王均安

Owner SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com