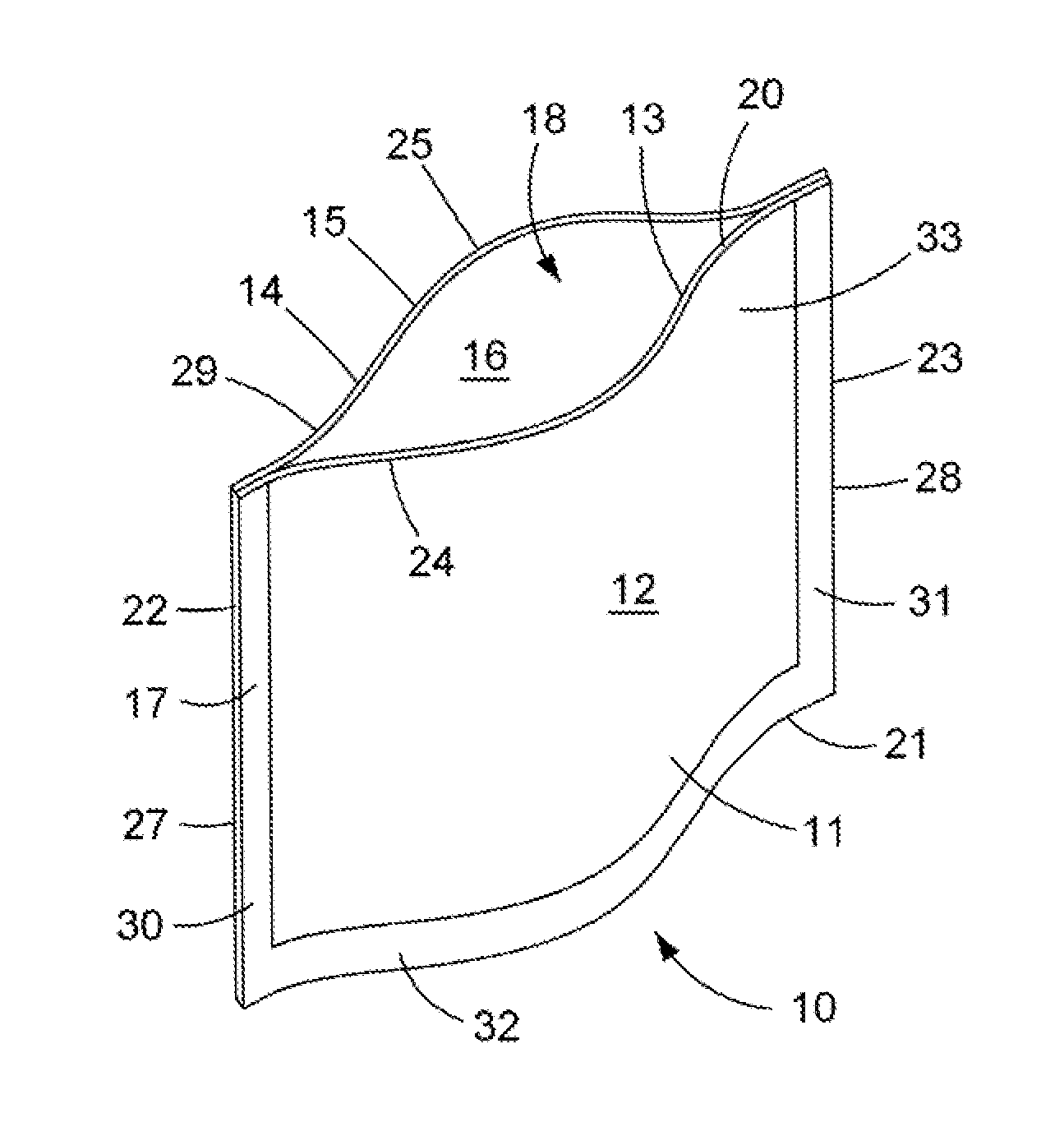

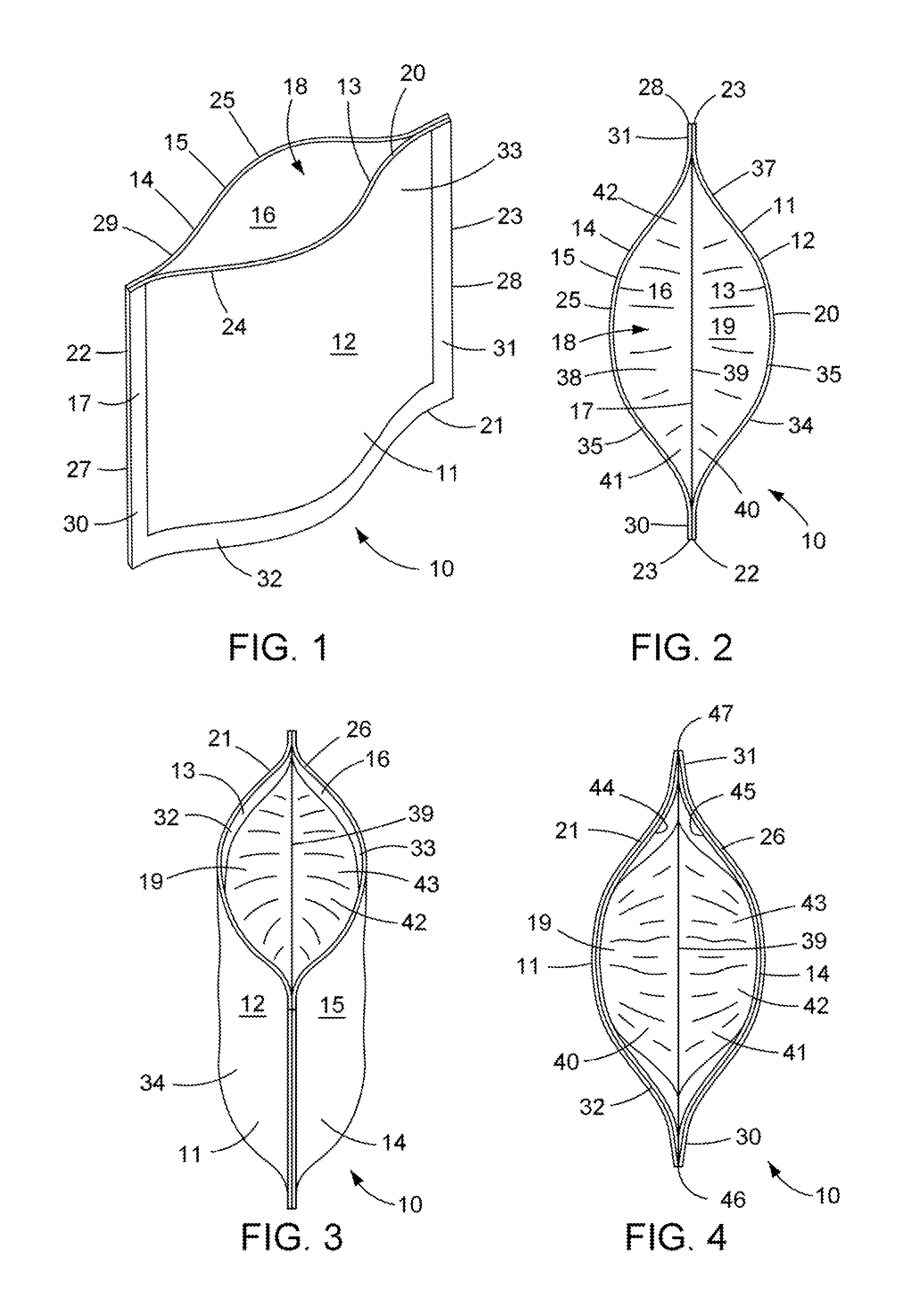

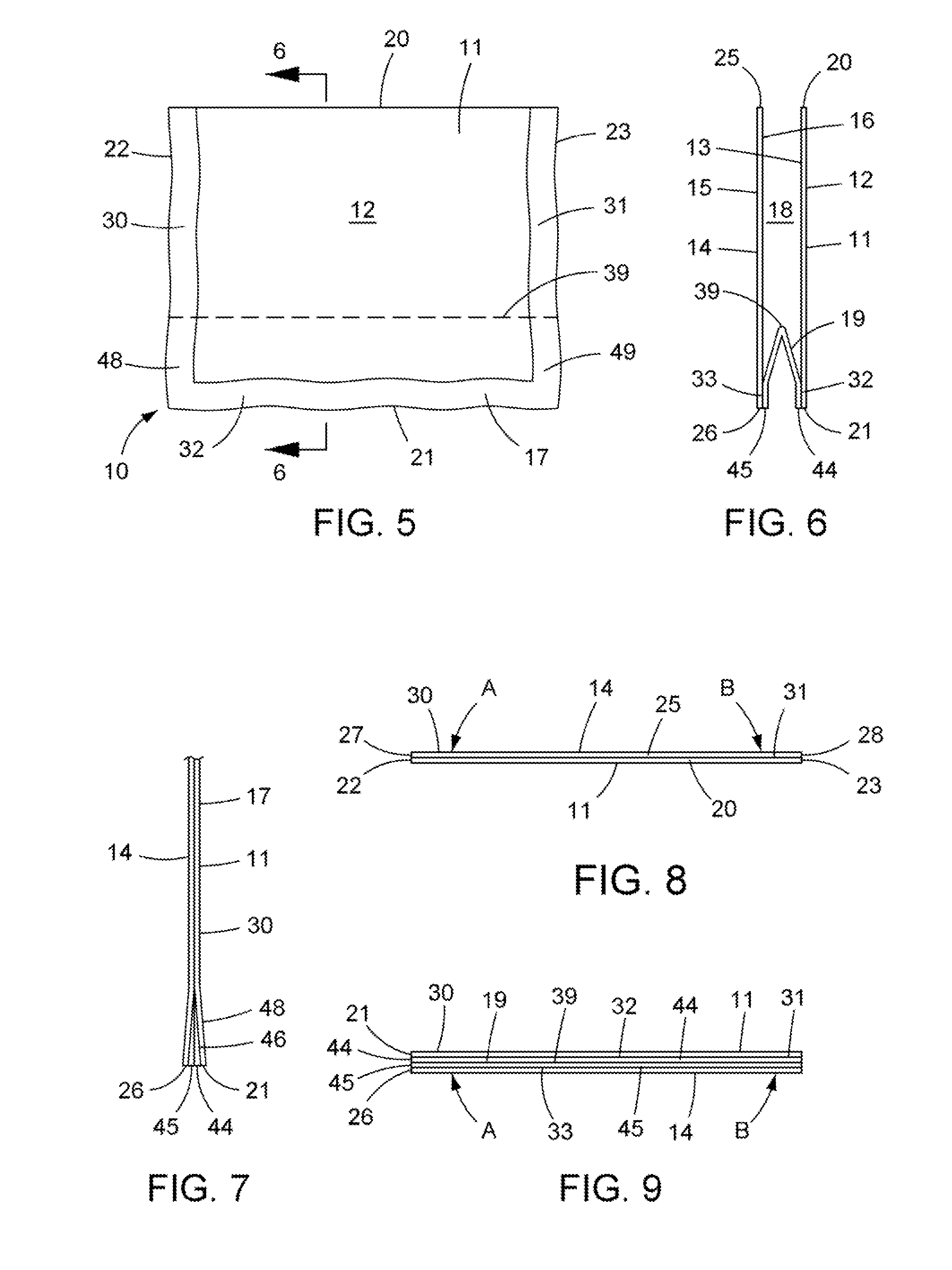

Self-forming container

a self-forming, container technology, applied in the field of packaging, can solve the problems of inability to manufacture previous attempts, high cost and complexity of manufacturing, packaging which combine heat shrinkable films with non-shrinkable films, etc., and achieve the effect of less heat shrinkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0127]In Example 1, a uniaxially stretched, heat shrinkable, monolayer film was made and its physical properties tested. A film comprising 70 wt. % of a cyclic olefin copolymer commercially available from Topas Advanced Polymers GmbH under the trade name Topas 8007F-400 was blended with 30 wt. % of a conventional ethylene octene-1 copolymer commercially available from The Dow Chemical Company under the trade name Attane NG 4701G (hereinafter COC:EAO blend). This blend was melt plastified in an extruder and extruded through a slot cast die at a temperature of from 180-250° C. onto a chill roll (temperature ˜55° C.) and subsequently uniaxially oriented in the machine direction by a slot cast MD stretch orientation process similar to that described above at a stretch orientation temperature of ˜85° C. The orientation ratio in the machine direction was 3:1. There was no transverse orientation stretching applied apart from passage of the film through the machine direction rollers. A samp...

example 2

[0130]Another container of the present invention was fabricated, as for Example 1, except with the following changes. The pair of nonshrink side wall panels was replaced with a different multilayer panel material which utilized unoriented PET. These panels were 5 inches high and 7 inches wide and also used a single gusset but having a fold 2¼ inches from the bottom edge. After heat activation, the bottom connecting wall shrank, however the container base was slightly distorted due to the low softening point of the material used in the sidewall relative to the heat activation temperature and coupled with the deep gusset fold and shrink forces attendant to the shrink film utilized.

example 3

[0131]Another container was made, as described for Example 2, except this container used nonshrink side wall panels which were approximately 5 inches high by 6 inches wide and a single gusseted, connecting panel with a 1½ inch fold. The side wall panels and connecting wall utilized the same materials as for Example 2. The container of example 3 was heat activated as for Example 2. There was much less distortion of the base of the example 3 container which result is believed due to use of a shorter fold depth in combination with a shorter panel width. The self-forming container of Example 3 was also equipped with a plastic, double track, reclosable zipper of the type which are commercially available from several manufacturers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrink | aaaaa | aaaaa |

| shrink | aaaaa | aaaaa |

| shrink | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com