Preparation method of siluer metal oxide electric contact material

A technology of oxide electrical and contact materials, applied in the direction of contact materials, etc., can solve the problems of complex oxide mixture procedures, difficult processing, uneven powder mixing in powder metallurgy, etc., to reduce the size of powder grains and improve processing Performance and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

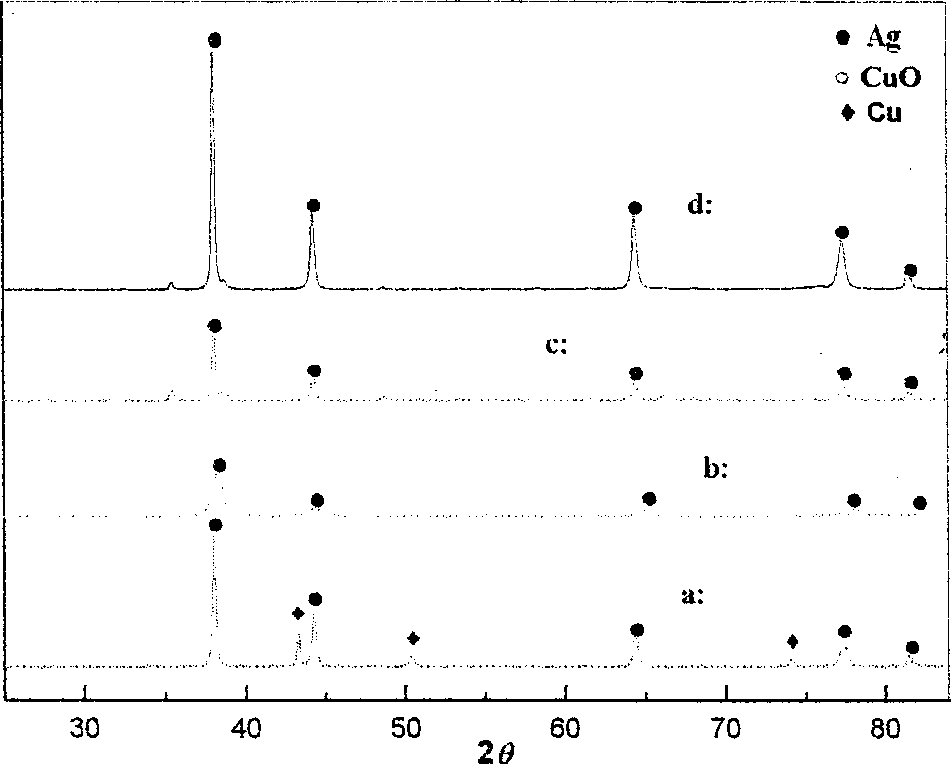

[0022] Mix 92wt% Ag powder with 8wt% Cu powder evenly, see figure 1 Curve a. The mixed powder is high-energy ball milled for 6 hours. At this time, Cu is completely dissolved in Ag to form ultra-fine Ag-Cu alloy powder (curve b); the powder after ball milling is vacuum pre-annealed at 200-350°C and then cooled at 450-600°C Oxidation in air produces a powder of CuO particles in which the oxide is dispersed in the Ag matrix (curve c); the oxidized powder is thermally processed to prepare AgCuO10 contacts (curve d). .

Embodiment 2

[0024] The mixed powder containing 8wt% of Cu powder and the rest of Ag powder is subjected to high-energy ball milling (high-energy ball milling can be carried out in vacuum, argon or air, and ball milling takes 2-8 hours) to obtain Ag-Cu alloy powder. The ball-milled powder is pre-annealed in vacuum at 200-350°C, and then cold-pressed, sintered, rolled, wire-drawn, and beaten into rivets. The rivet contacts were internally oxidized at 700°C to form AgCuO10 contacts.

Embodiment 3

[0026] The mixed powder of Ag powder and 10-20% Sn powder with a weight ratio of 80-90%, respectively, is high-energy ball milled in a low-oxygen atmosphere for 2-10 hours to obtain Ag-Sn binary alloy powder, and the ball-milled powder is in Oxidation treatment at 400-650°C produces diffusely distributed SnO in the silver matrix 2 Particles, SnO 2 The particle size is not greater than 5 μm. AgSnO was prepared by cold pressing, sintering, and hot repressing the internally oxidized powder. 2 contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com