System and method for testing jiggle contact resistance

A technology of contact resistance and contact voltage, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve problems such as unfavorable real-time observation and analysis, limited number of channels, inaccurate measurement, etc., and is conducive to real-time observation. Analyze, reduce the fluctuation of fretting amplitude, and improve the effect of experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

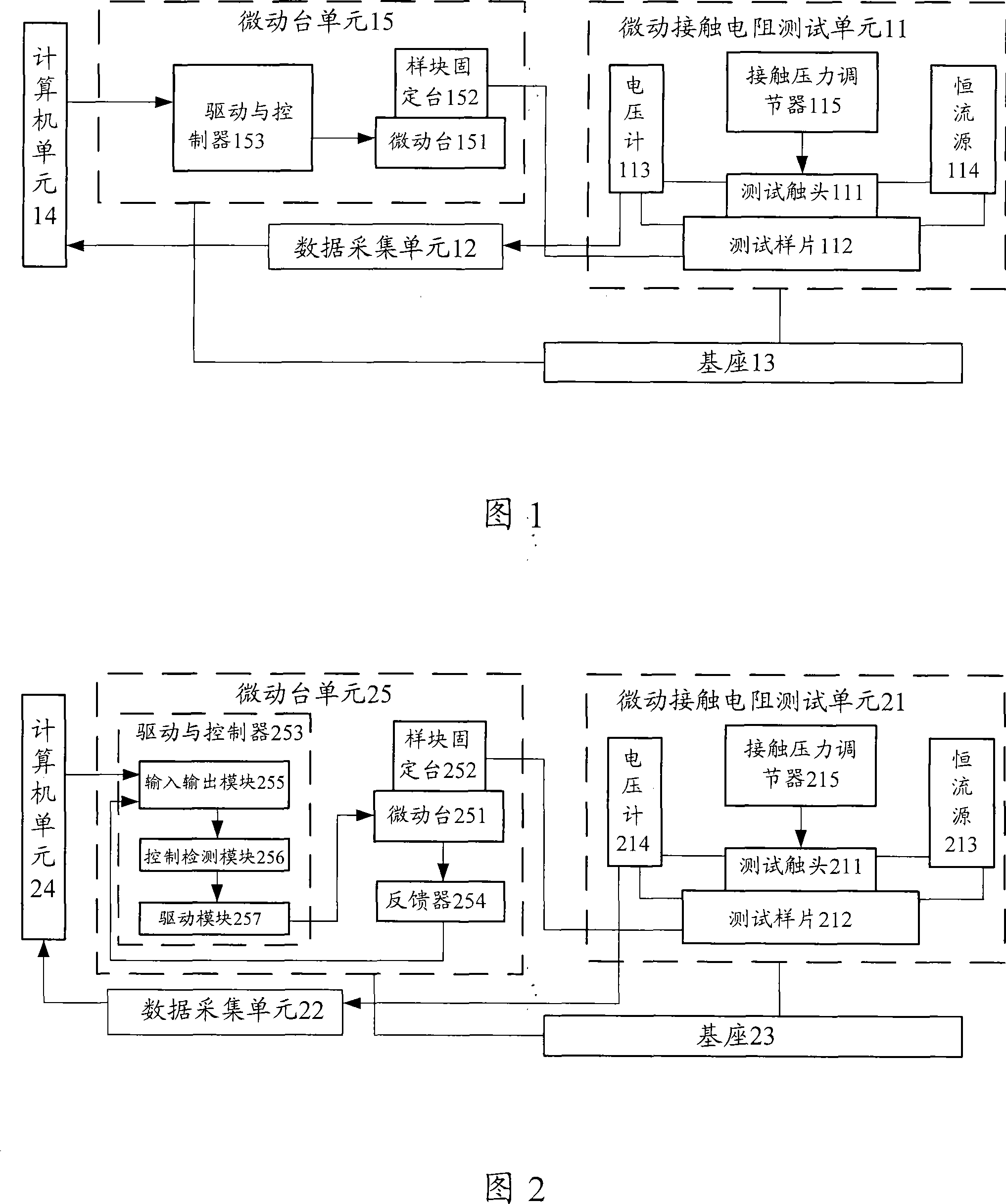

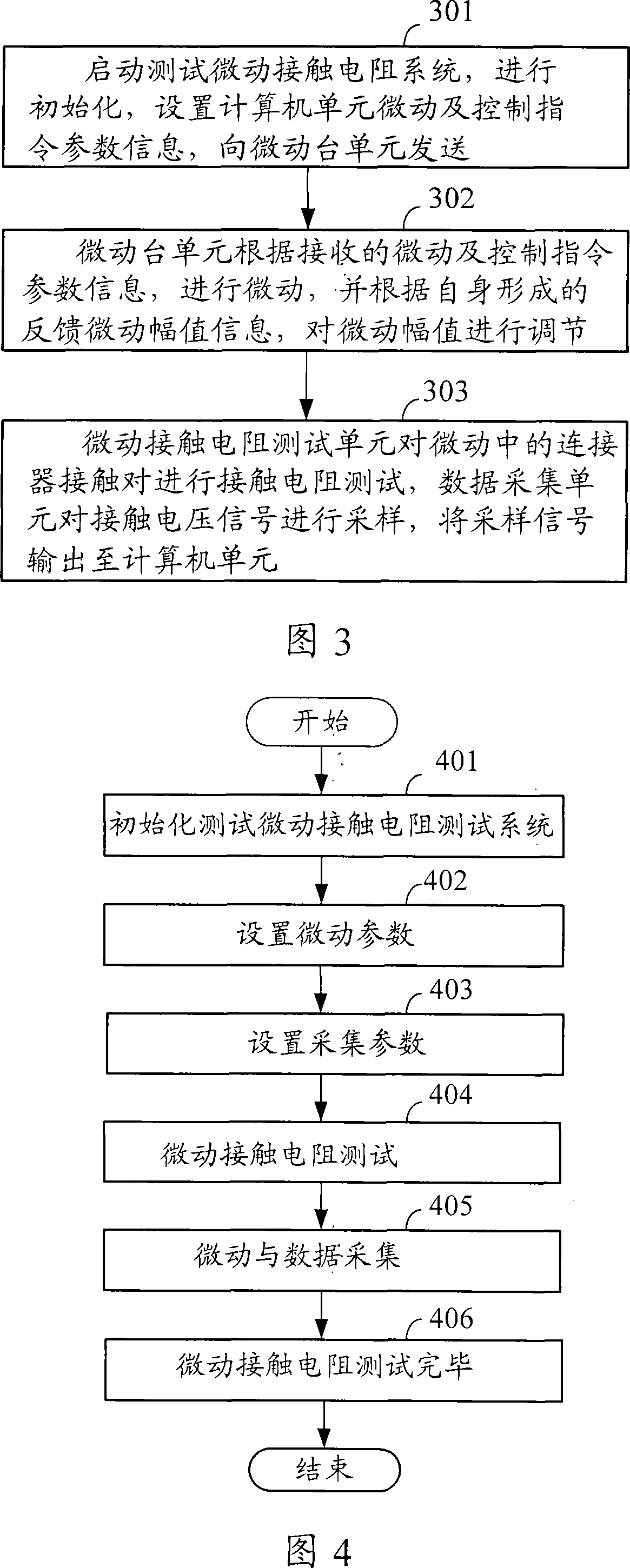

[0069] In the present invention, the micro-motion parameters are set by the computer, and the parameter instructions are sent to the drive and control unit. The drive and control unit controls the micro-motion of the two micro-motion platforms according to the instructions. The sample is fixed on the micro-motion platform, and the contact is vertical to the fixture through the linear bearing Contact with the sample to form a contact pair, the force applying mechanism applies the contact pressure on the contact, the constant current source provides a constant current to the contact pair, the data acquisition card in the voltmeter collects the contact voltage between the sample and the contact, and passes through the PCI bus Transfer to a computer; the computer processes the sampled data and saves it to disk.

[0070] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com