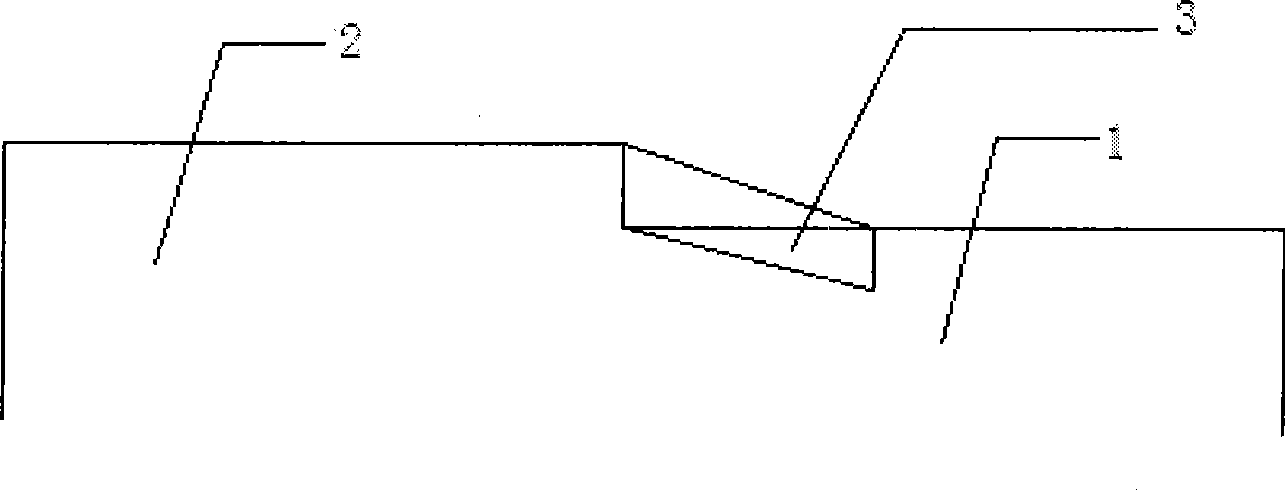

Rapid patching material for cement concrete pavement faulting of slab ends and patching method thereof

A technology for cement concrete and repairing materials, applied in road repair, roads, roads, etc., can solve the problems of large shrinkage, low flexural strength, and high cost of cement mortar, and achieve the effects of fast growth, low shrinkage, and fast strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

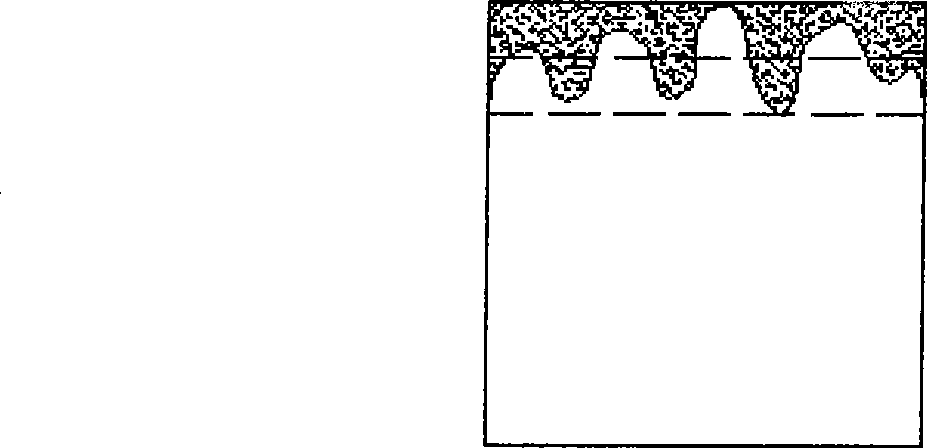

Method used

Image

Examples

Embodiment 1

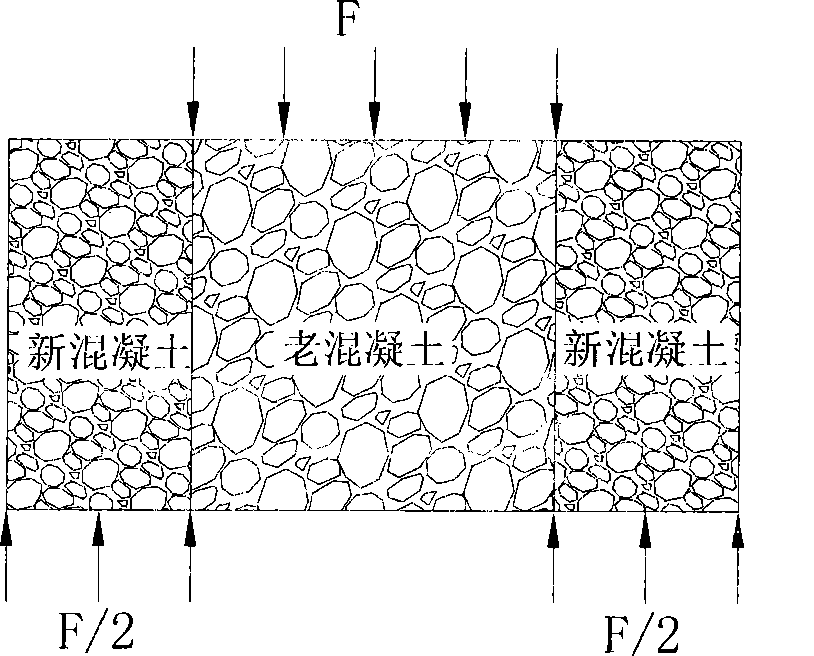

[0019] Embodiment 1: One of the fast repairing materials for cement concrete pavement dislocation——styrene-butadiene emulsion modified rapid-hardening sulphoaluminate cement mortar, whose components include cement, water, fine aggregate and styrene-butadiene latex; between the components The weight ratio of the concrete is: cement ≤ 500kg per cubic meter; the water-cement ratio is 0.3-0.36, and the water content in the water-cement ratio includes the water content in styrene-butadiene latex; the solid content in styrene-butadiene latex is 5-10% of cement ; The weight of each cubic meter of repair material is about 2400kg, and the content of fine aggregate is the total weight of each cubic meter of repair material minus the weight difference of the other three components.

Embodiment 2

[0020] Embodiment 2: The second quick-fixing material for cement concrete pavement dislocation——styrene-butadiene emulsion modified rapid-hardening sulfoaluminate cement concrete, whose components include cement, water, fine aggregate, coarse aggregate and styrene-butadiene latex; The weight ratio between the components is: per cubic meter of concrete cement ≤ 500kg; the water-cement ratio is 0.3-0.36, the water content in the water-cement ratio includes the water content in styrene-butadiene latex; the solid content in styrene-butadiene latex is cement 5-10%; the weight of each cubic meter of repair material is about 2400kg, the total content of coarse aggregate plus fine aggregate is the total weight of each cubic meter of repair material minus the weight difference of the other three components, and the sand rate is Fine aggregate / (fine aggregate + coarse aggregate) is 30-36%.

[0021] According to the design theory of concrete mix ratio, crushed stone (coarse aggregate) re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com