Compositions containing water control treatments and formation damage control additives, and methods for their use

a technology of additives and water control treatments, applied in the field of subterranean formation treatment, can solve the problems of reducing the economic return and life of the well, increasing the post-production cost, and increasing the quantity of aqueous impurities, so as to improve the efficiency and cost-effectiveness of hydrocarbon treatment, reduce the steps of treating these conditions, and improve the efficiency of the hydrocarbon treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Compositions Containing Scale Control Agent and RPM

[0099] PSI-720 (BJ Services Company; Houston, Tex.), a phosphinocarboxylic acid polymer (prepared as a 50 wt. % solution in water) was selected as an exemplary scale control agent. AquaCon™ (BJ Services Company; Houston, Tex.), a polyacrylamide-based terpolymer containing sulfonated functional groups, was selected as an exemplary relative permeability modifier. A series of mixtures, A-G, were prepared at room temperature, as shown in Table 1, below.

TABLE 1RPM and Scale Control Agent MixturesAmt. PSI-720Mixture(wt. %)Amt. AquaCon ™ (wt. %)A (control)100B1000C9010D7525E5050F1090G0100

12 wt. % KCl in water.

example 2

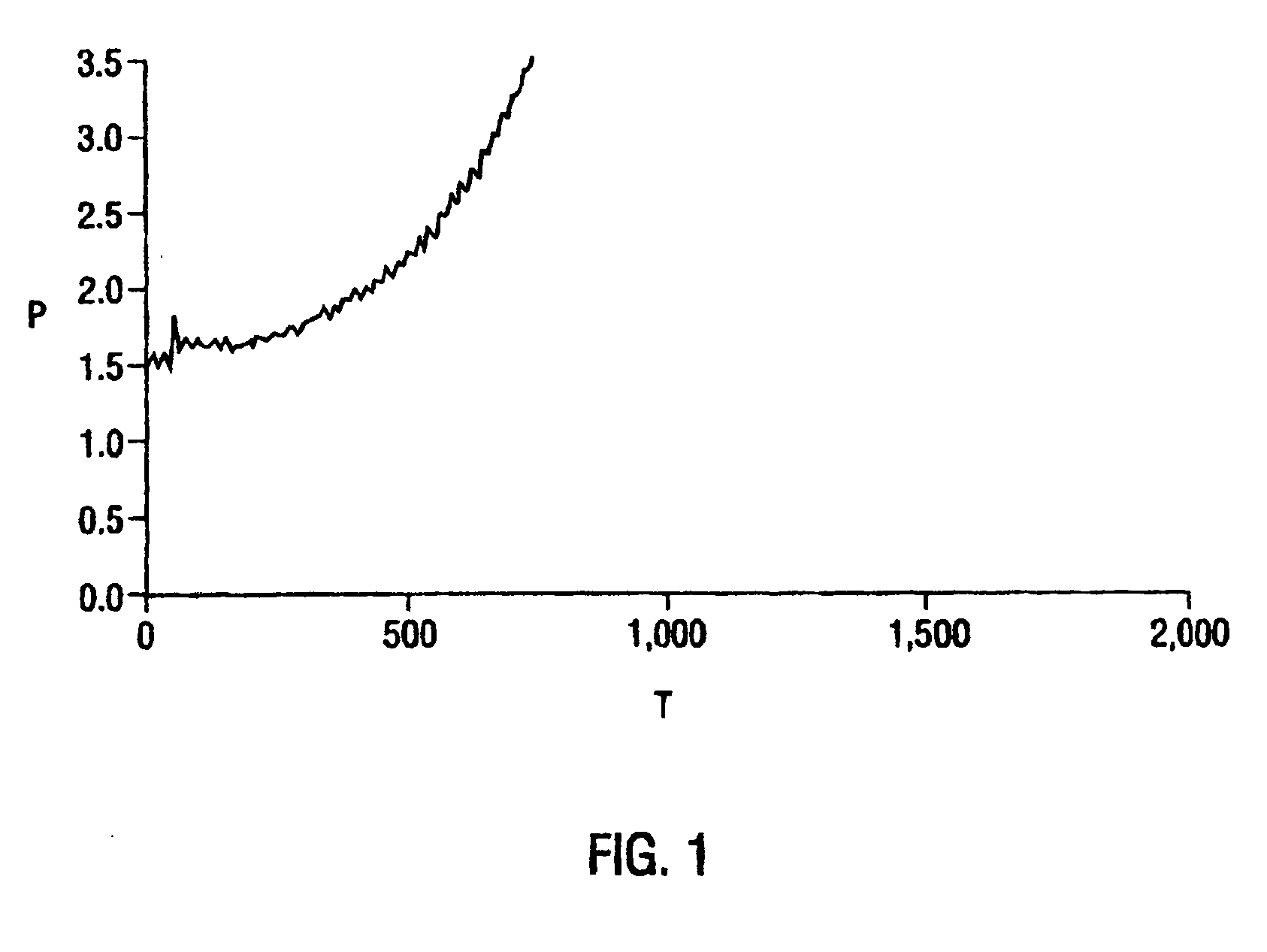

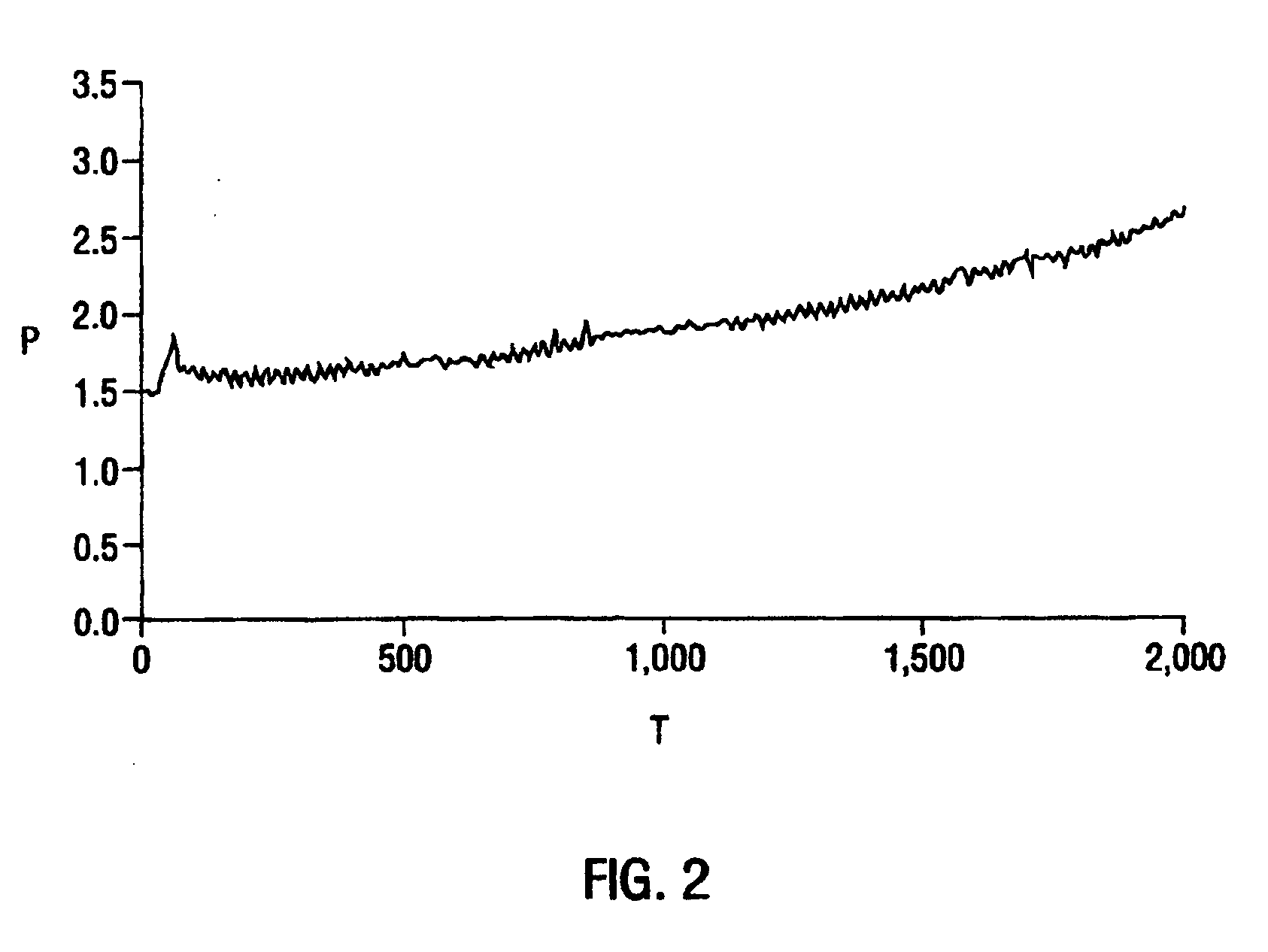

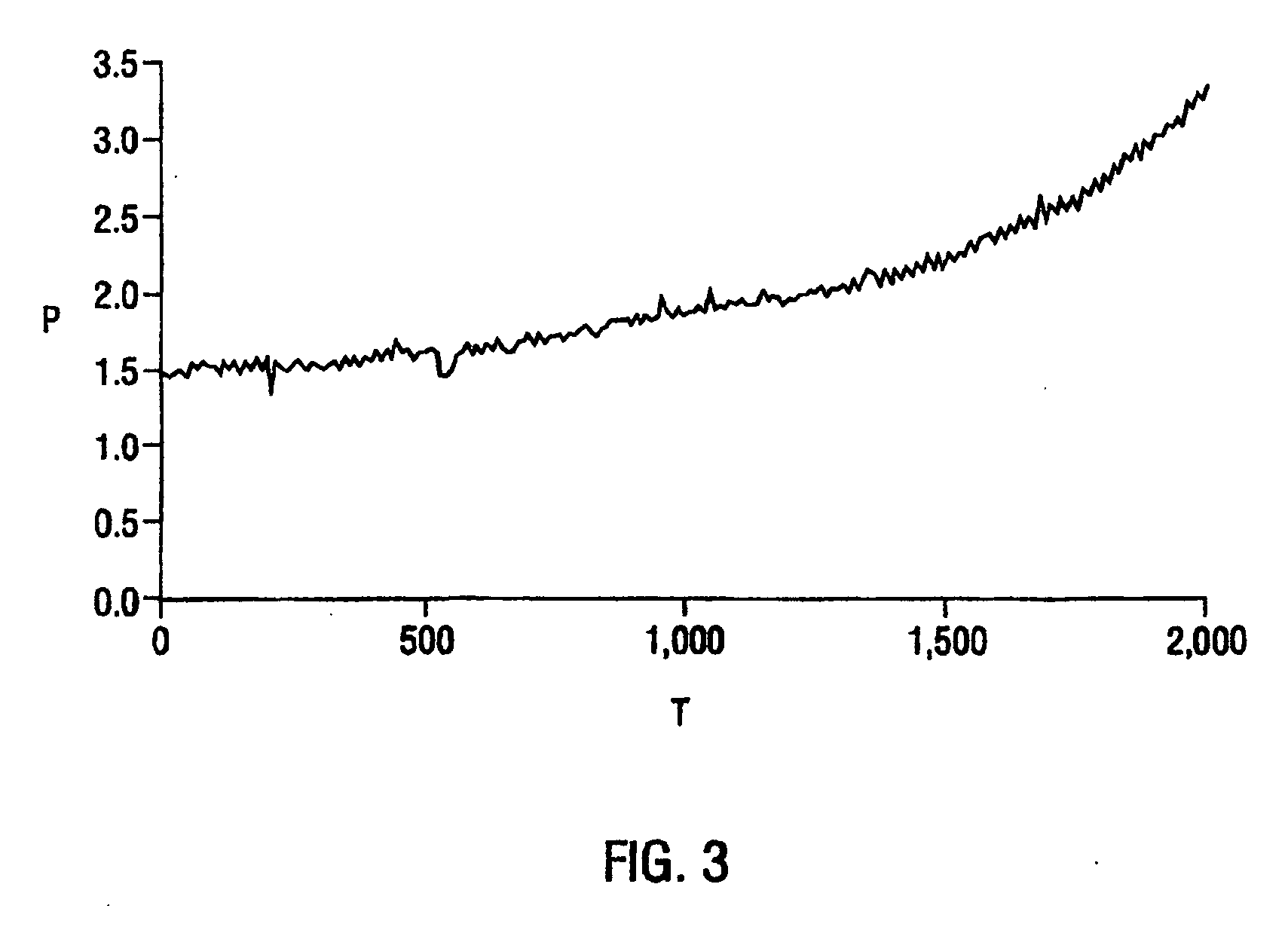

Tube Blocking Test Results

[0100] A tube blocking test was used to assay the effect caused by combining a scale control agent and a relative permeability modifier, if any. The test system comprised peristaltic pumps, a mixing “tec”, a ⅛-inch (0.3175 cm) coil of stainless steel tubing, and a 0.02 inch (0.05 cm) test coil of PEEK tubing.

[0101] Each of the mixtures described in Example 1 was mixed with test brine (2 wt. % potassium chloride in water) in an amount sufficient to give a final concentration of about 25 ppm PSI-720. This value was selected as it is slightly under the minimum scale to control agent concentration.

[0102] The two brine solutions were used to form a calcium carbonate scale precipitate. The first was a “cationic brine”, containing about 24,000 ppm sodium chloride, about 1,050 ppm sodium sulfate, about 6,610 ppm sodium bicarbonate, and about 4,610 ppm sodium acetate. The second brine prepared was an “anionic brine”, containing about 24,000 ppm sodium chloride, a...

example 3

Stability of Compositions at Room Temperature

[0107] The mixtures prepared as described in Example 1 were kept at room temperature for three days. At the end of this period, no precipitation, gelling, or other signs of 10 incompatibility were observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com