Induction excitation type mixed excitation brushless synchronous motor

A hybrid excitation and synchronous motor technology, applied to synchronous motors with stationary armatures and rotating magnets, controlling generators through magnetic field changes, magnetic circuit shape/style/structure, etc., can solve problems such as low excitation efficiency, and achieve The excitation method is simple, the effect of overcoming the large armature reaction and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

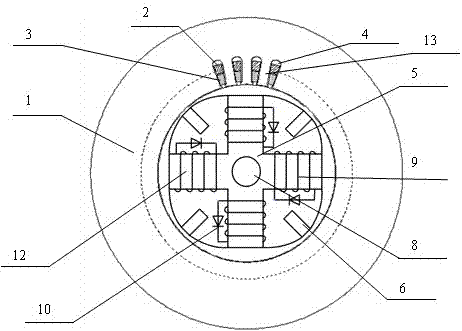

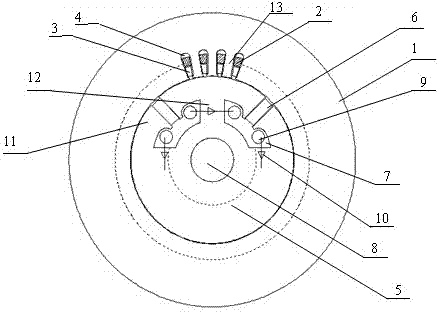

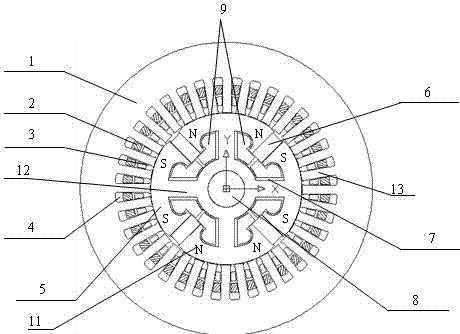

[0014] There are many ways to implement the present invention. The motor can be divided into a rotating magnetic pole type and a rotating armature type. The stator core can be a salient pole structure or a hidden pole structure, and the armature winding can be any AC winding form. The rotor core 5 can be a salient pole structure or a recessive pole structure, and the permanent magnets 6 are placed on the rotor core 5 .

[0015] Control attached figure 1 , Induction excitation hybrid excitation brushless synchronous motor, its structure is that the motor adopts two sets of excitation sources, including permanent magnet 6 and electric excitation winding, permanent magnet 6 is placed in the rotor; electric excitation winding is divided into stator excitation winding and rotor excitation winding 9 ; The stator part includes a stator core, an armature winding 2, a stator excitation winding 3, an end cover, and a casing, wherein the armature winding 2 and the stator excitation win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com