Stator Partition Alternating Pole Hybrid Excitation Motor

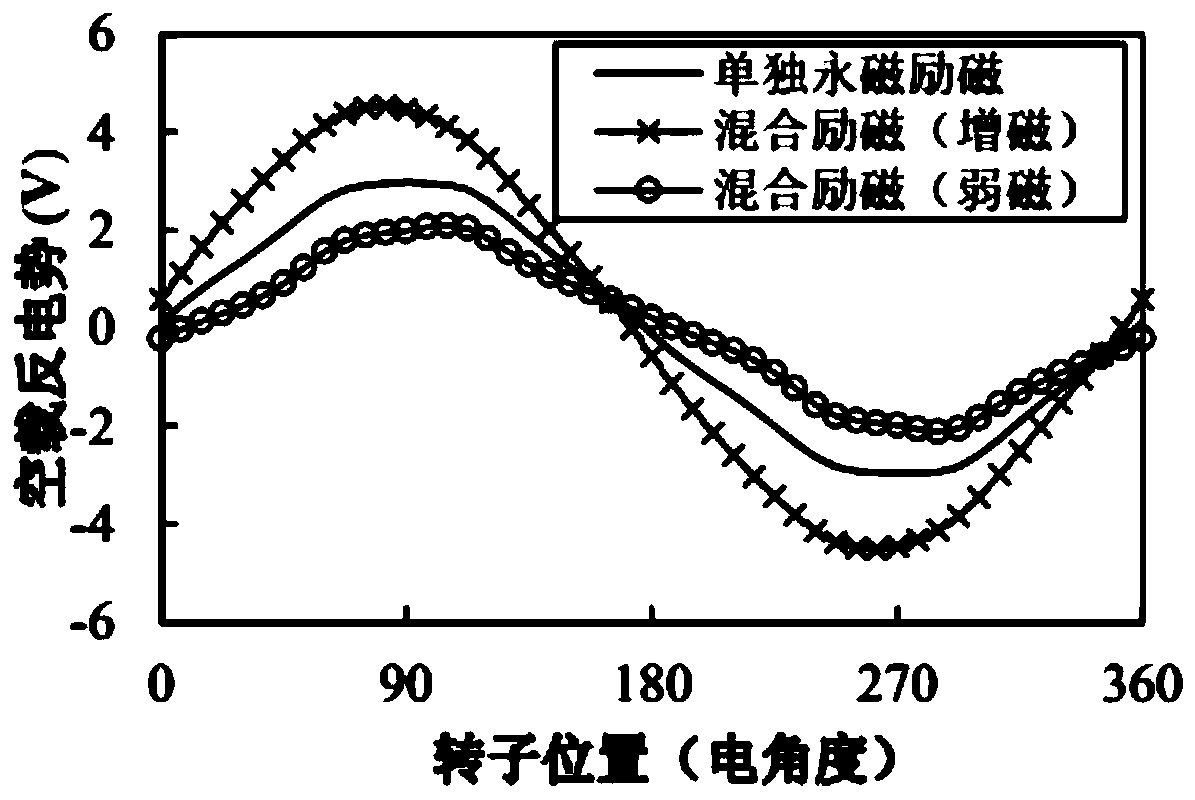

A hybrid excitation motor, partitioned technology, applied in the direction of synchronous machines, electromechanical devices, electrical components, etc., can solve the problems of limited magnetic field adjustment capability, low efficiency and power factor in the speed-up interval of field-weakening, and limited speed regulation range. Achieve the effect of brushless excitation and avoid irreversible demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

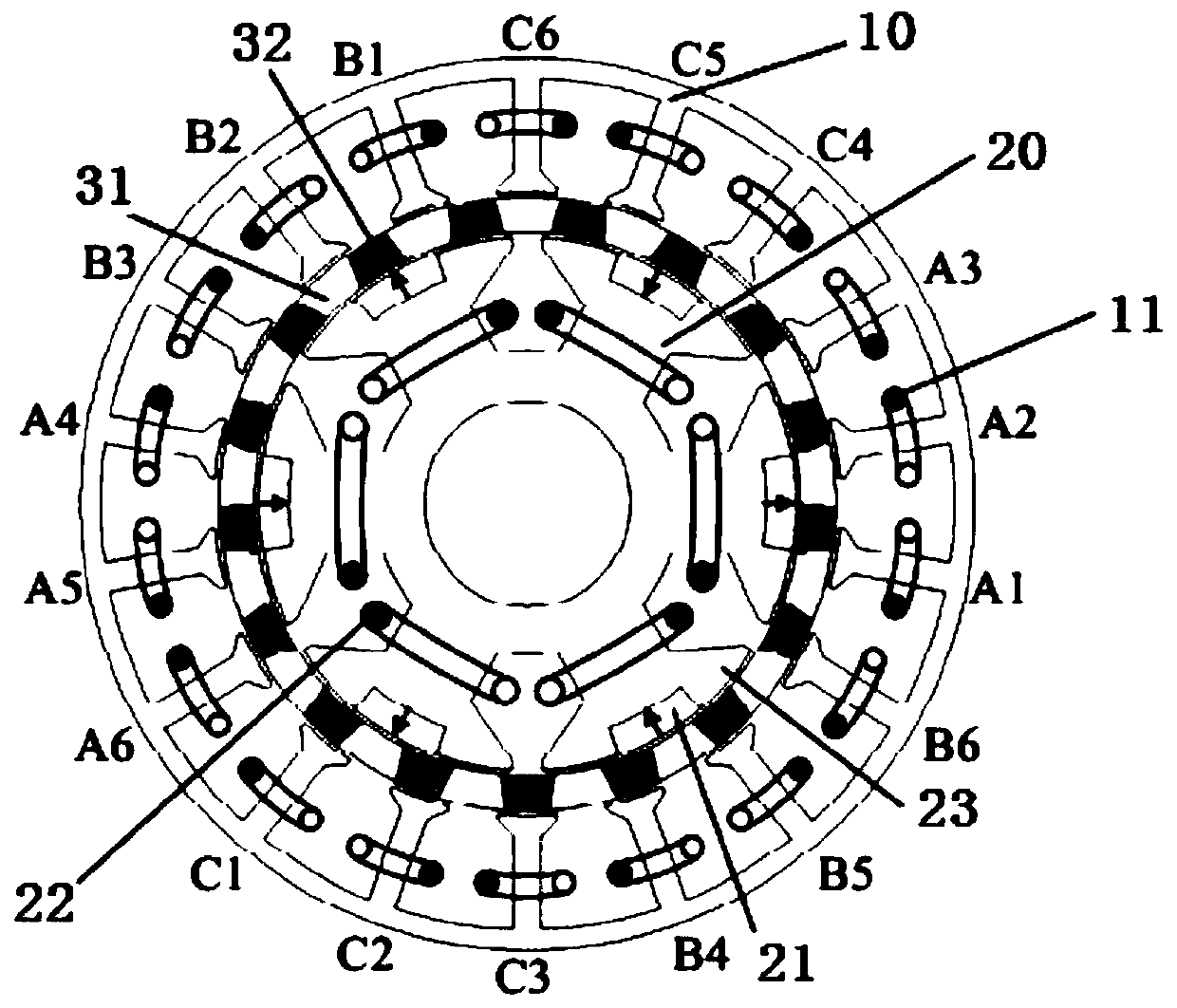

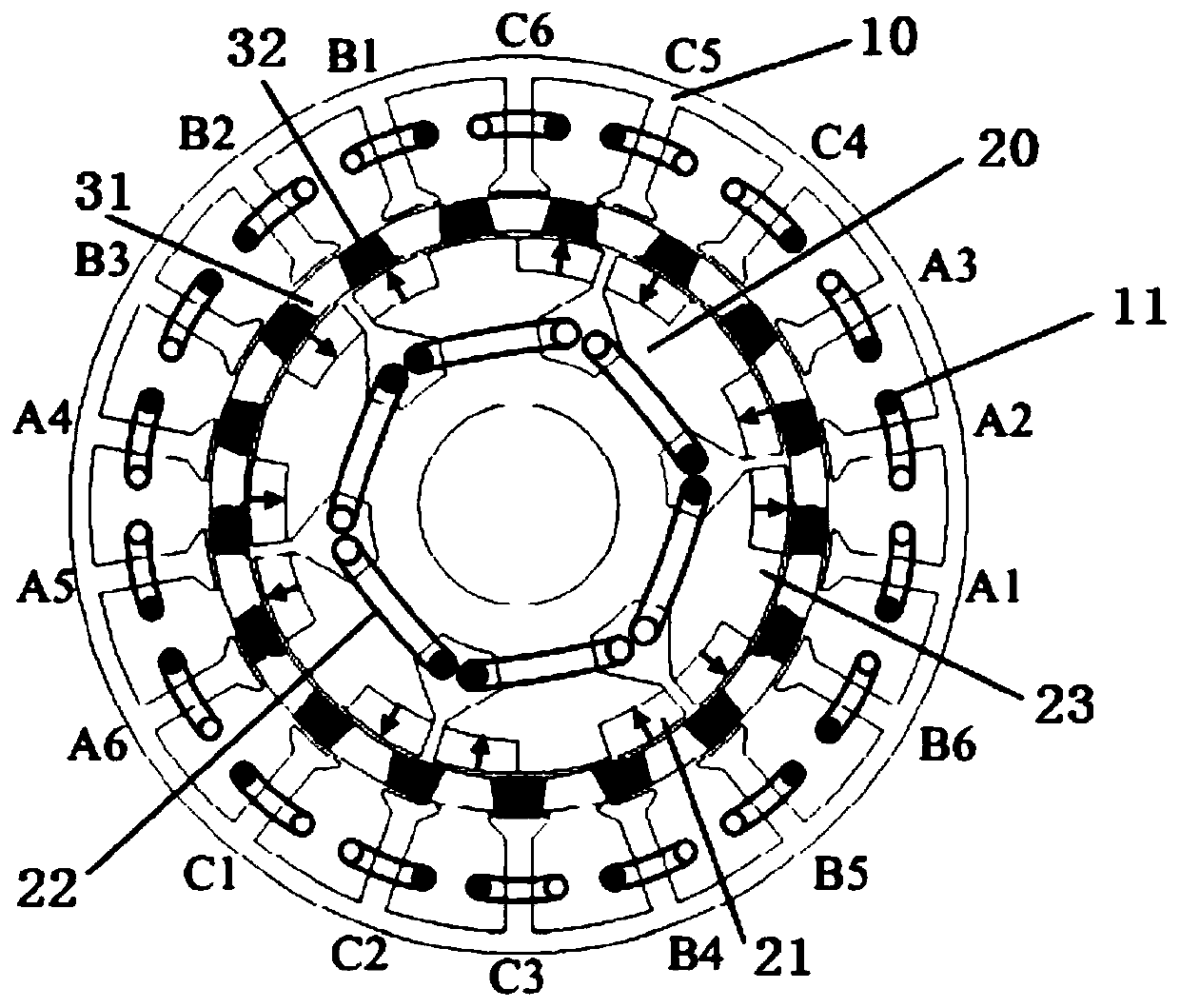

[0032] Such as figure 1 and figure 2 As shown, a stator segmented alternating pole hybrid excitation motor includes an armature winding 11, an excitation winding 22, a stator 10 where the armature winding is located, a rotor, a stator 20 where the excitation winding is located, and a central shaft.

[0033] The stator where the armature winding is located and the stator where the field winding is located are respectively arranged on both sides of the rotor, the stator where the armature winding is located is the outer stator, and the stator where the field winding is located is the inner stator.

[0034] There is an air gap 1 between the stator where the armature winding is located and the rotor, and there is an air gap 2 between the rotor and the stator where the field winding is located.

[0035] The rotor can be connected to the central shaft through bearings, and the central shaft does not move to form a direct drive motor; the rotor can also be fixedly connected to the ...

Embodiment 2

[0060] Embodiment 2 is basically the same as Embodiment 1, except that the structure of the stator where the field winding is located is replaced with that of the stator where the armature winding is located. That is to say, the stator where the field winding is located is the outer stator, and the stator where the armature winding is located is the inner stator.

[0061] At this time, the specific structure of the stator tooth where the excitation winding is located is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com