Semi-automatic efficient steel pipe outer wall cleaning device

A cleaning device and semi-automatic technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult cleaning work, dust falling, strong work intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0020] The invention designs a semi-automatic high-efficiency steel pipe outer wall cleaning device. The user only needs to fix the steel pipe, then adjust the movable support to different positions, and then slightly clean the two ends of the steel pipe to complete the whole cleaning.

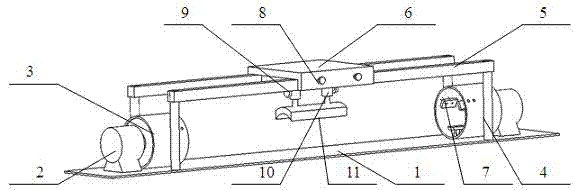

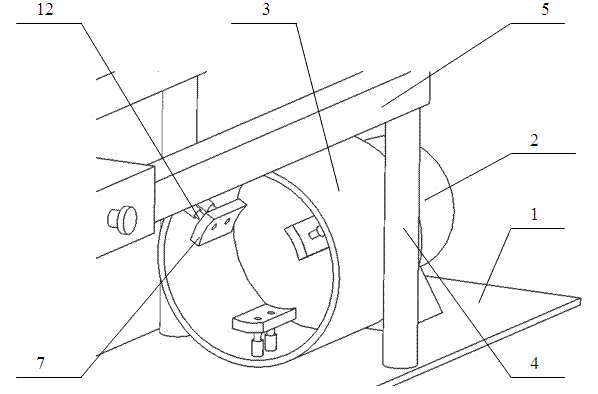

[0021] As an embodiment of the present invention, the present invention provides a semi-automatic high-efficiency steel pipe outer wall cleaning device, including a support plate 1, a motor 2, a pipe fixing cover 3, a pillar 4, a guide rail support 5, a movable support 6, a bent plate positioning plate 7, A brush fixing frame 11 and a clamping cylinder 12, a pair of pipe fixing covers 3 are arranged on the support plate 1, and one side of the pipe fixing covers 3 is connected to the corresponding motor 2 rotating shaft, and the motor 2 is on the support plate 1, so The motor 2 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com