Precast panel mounting system

a technology for mounting brackets and prefabricated panels, which is applied in the direction of building components, ceramic shaping apparatus, structural elements, etc., can solve the problems of affecting the overall durability and value of the building, and the leakage at the roof-to-wall junction, etc., to achieve uniform air space and facilitate the placement of mounting brackets. , the effect of convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

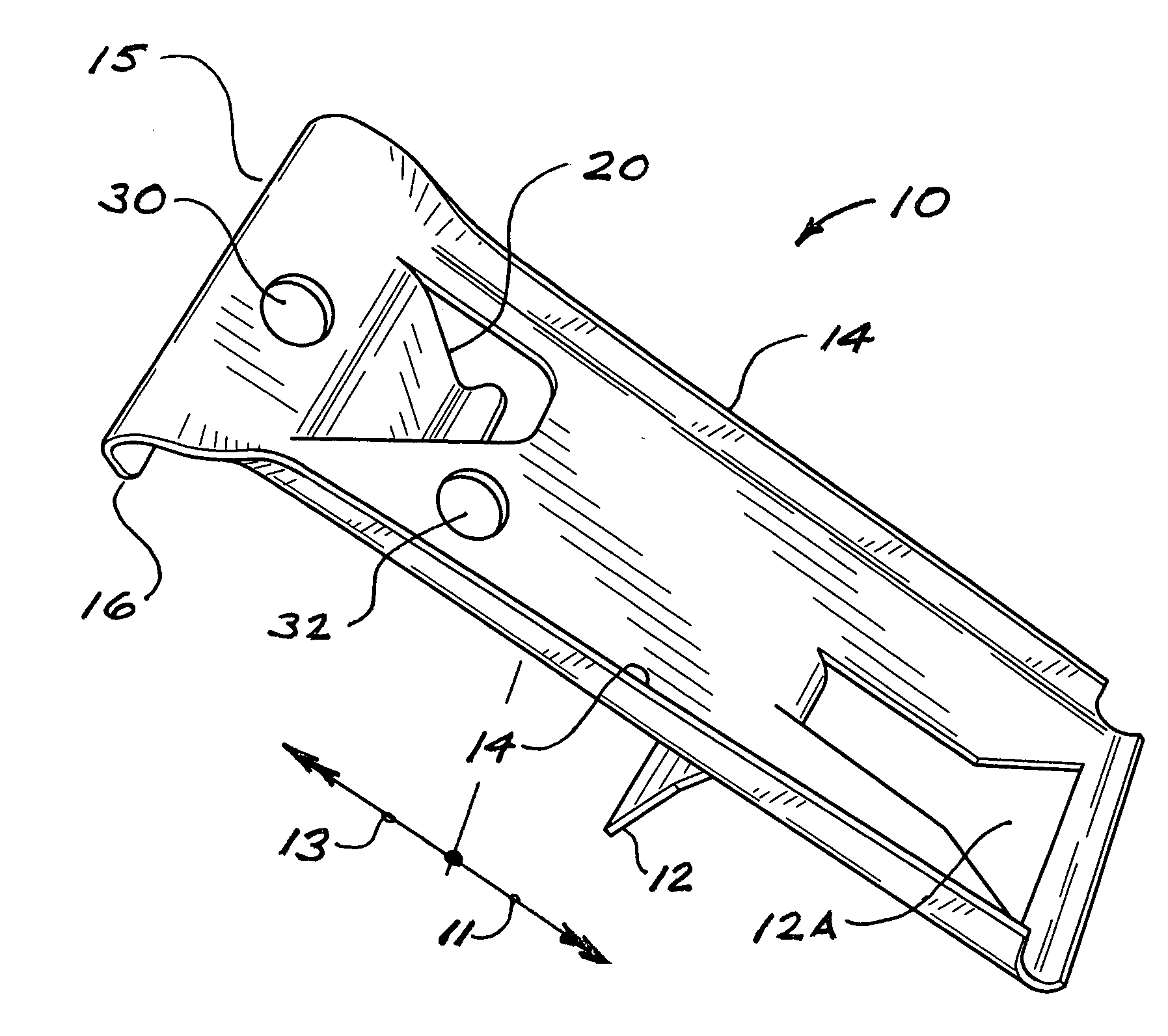

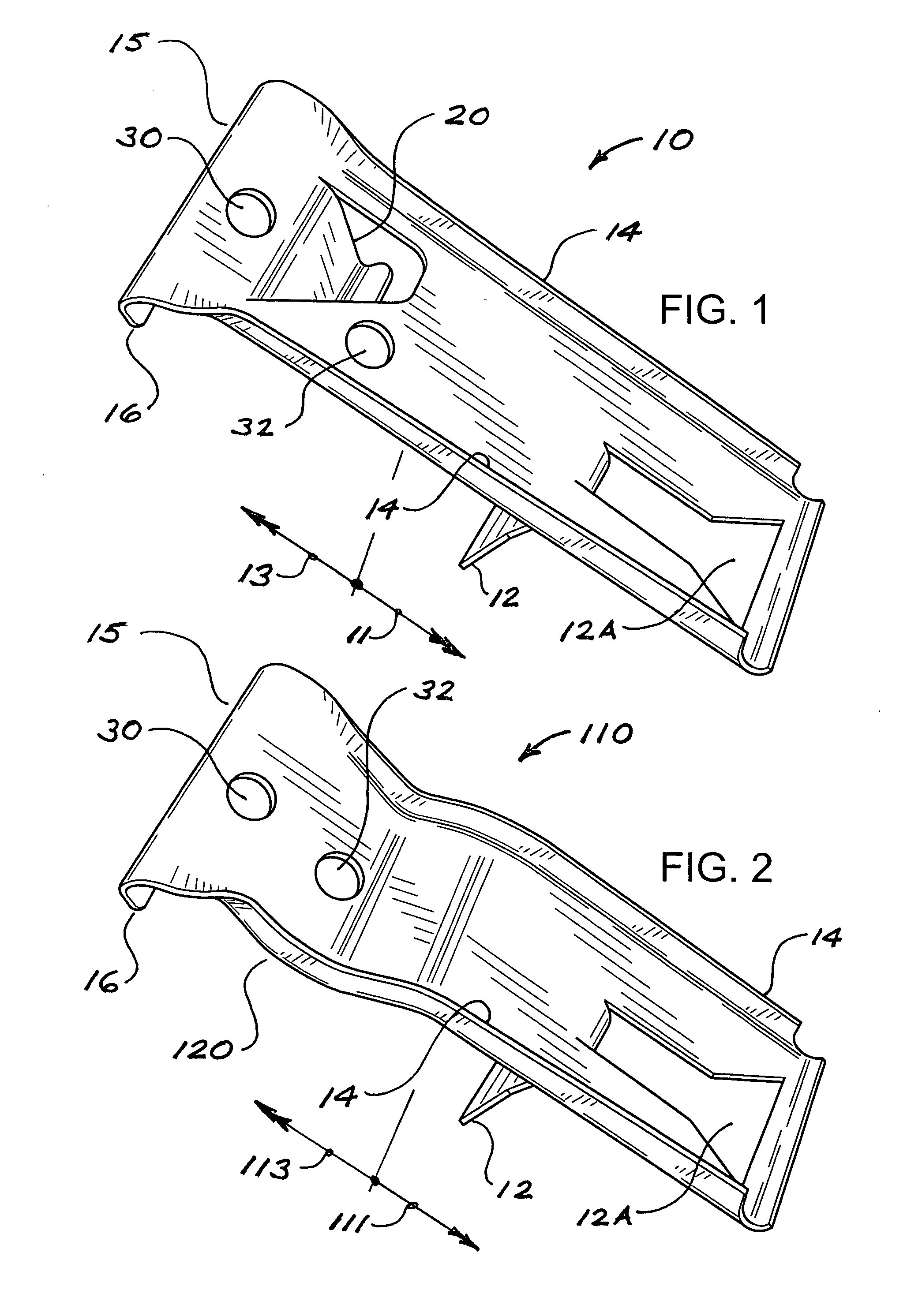

[0053] Referring to FIG. 1, a rigid, elongate mounting bracket 10 in accordance with the invention has an embedment portion 11 and a contiguous extension portion 13. The point of demarcation between embedment portion 11 and extension portion 13 is not precisely defined, but will coincide with the rear face of a precast cladding panel in which bracket 10 is embedded, as will be described in detail herein. Bracket 10 is preferably fashioned from a corrosion-resistant metal, such as stainless steel, galvanized steel, or plated steel, but other materials may also be used provided they have suitable physical properties. Persons skilled in the art will appreciate that bracket 10 could be fashioned in accordance with any of several known fabrication methods. In the preferred embodiment shown in FIG. 1, however, bracket 10 is cold-formed from sheet stock. Bracket 10 will preferably be formed with side edge flanges 14 for increased stiffness, but these are not essential to the invention.

[005...

second embodiment

[0057]FIG. 2 illustrates a mounting bracket 110 in accordance with a Bracket 110 has several features in common with bracket 10, as indicated by the use of common reference numerals. What distinguishes bracket 110, however, is that the abutment means is provided as a shoulder 120 formed integrally with bracket 110. For greater clarity in differentiating bracket 110 from bracket 10, the embedment portion and extension portion of bracket 110 are indicated by reference numerals 111 and 113 respectively, with shoulder 120 forming part of extension portion 113.

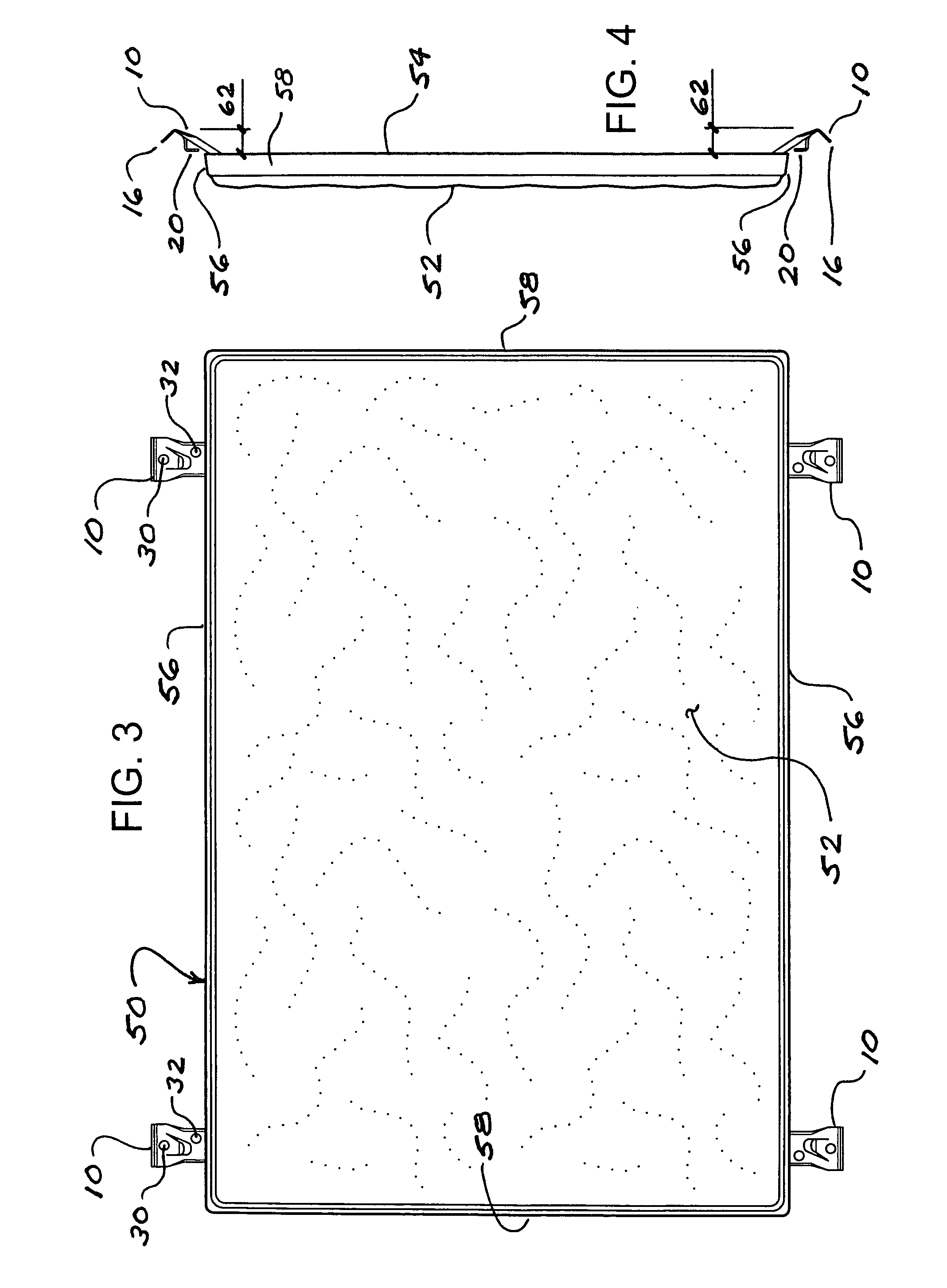

[0058]FIG. 3 is an elevation of a typical precast cladding panel 50 formed with mounting brackets 10 in accordance with the present invention; FIG. 4 is an end view (or side view) of the panel of FIG. 3. As illustrated, panel 50 has a front face 52 (which may be flat or textured as desired), a generally planar rear face 54, two longitudinal edges 56 (which may be upper or lower edges, depending on the orientation of panel 50), and...

third embodiment

[0088]FIGS. 16 and 17 illustrate the mounting bracket of the present invention. As shown in FIG. 16, alternative bracket 210 is formed from metal wire of a gauge suitable to provide the structural strength and stiffness required for specific panel applications. Bracket 210 has embedment portion 211 and extension portion 213 analogous to embedment portion 11 and extension portion 13 of the previously-described bracket 10. Bracket 210 is twist-formed to create a fastener opening 30 analogous to that of bracket 10, and to form abutment means in the form of a shoulder 220 analogous to shoulder 120 of alternative bracket 110.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com