MEMS silicon microphone and preparation method for the same

A silicon microphone and silicon-based technology, which is applied in the field of MEMS silicon microphone and its preparation, can solve the problems of failing to meet the sensitivity requirements of the vibrating film, reducing the sensitivity of the vibrating film, and complicating the preparation process, so as to improve sensitivity and yield, avoid Suction and possibility, good consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

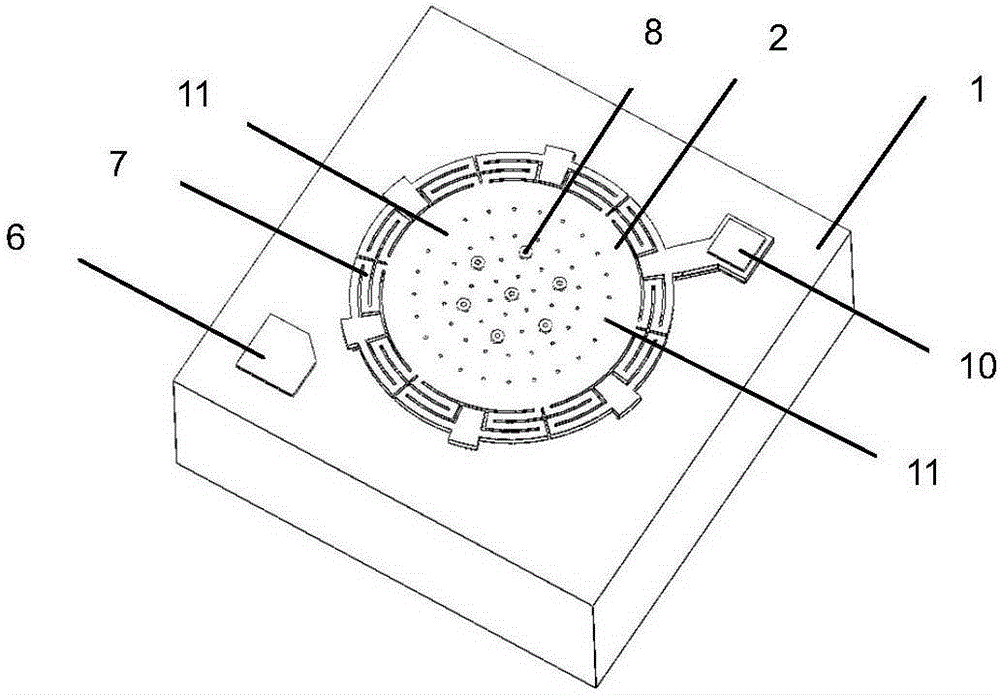

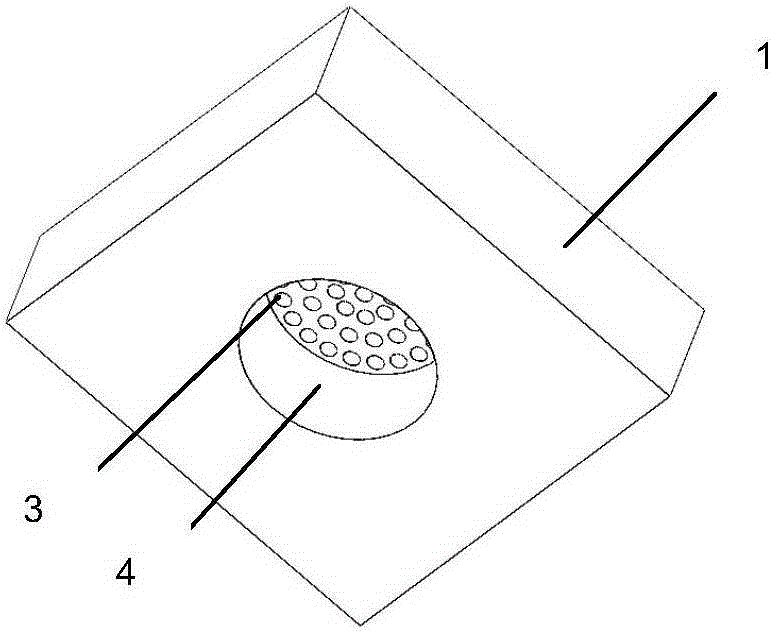

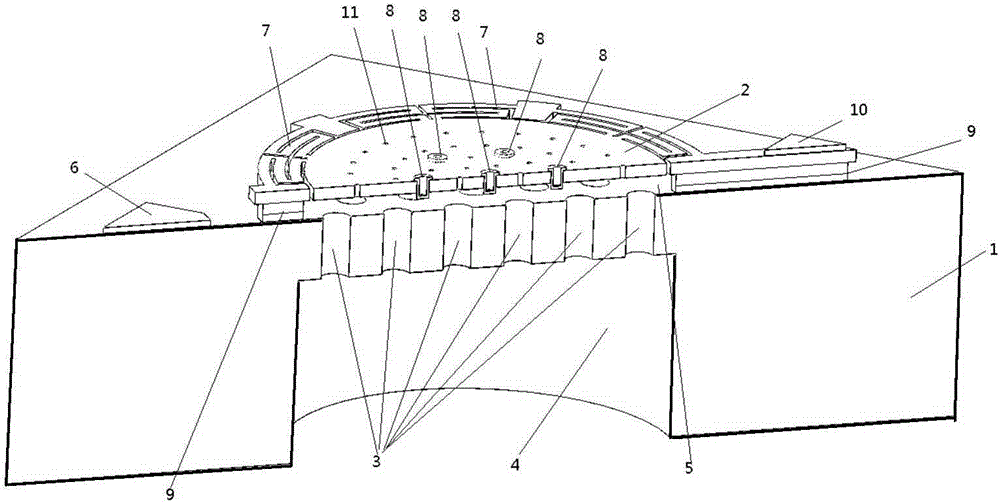

[0046] Combine below Attached picture The present invention will be further described with specific examples, but the protection scope of the examples of the present invention is not limited to the following examples.

[0047] In view of the deficiencies and defects in the prior art, the present invention provides a MEMS silicon microphone and its preparation method. The technical solution of the invention can be realized on the basis of simplifying the manufacturing process of the MEMS silicon microphone, and can also meet the requirements of sensitivity, reliability and output. aspects of demand.

[0048] In order to thoroughly understand the present invention, detailed steps and detailed structures will be provided in the following description, so as to illustrate the technical solution of the present invention. Preferred embodiments of the present invention are described in detail below, however, the present invention may have other embodiments besides these detailed des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com