Graphene oxide film, preparation method and applications thereof

A graphene membrane and graphene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve high water permeation selectivity and permeation flux, and the effects of economic and technical means and environmental protection technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

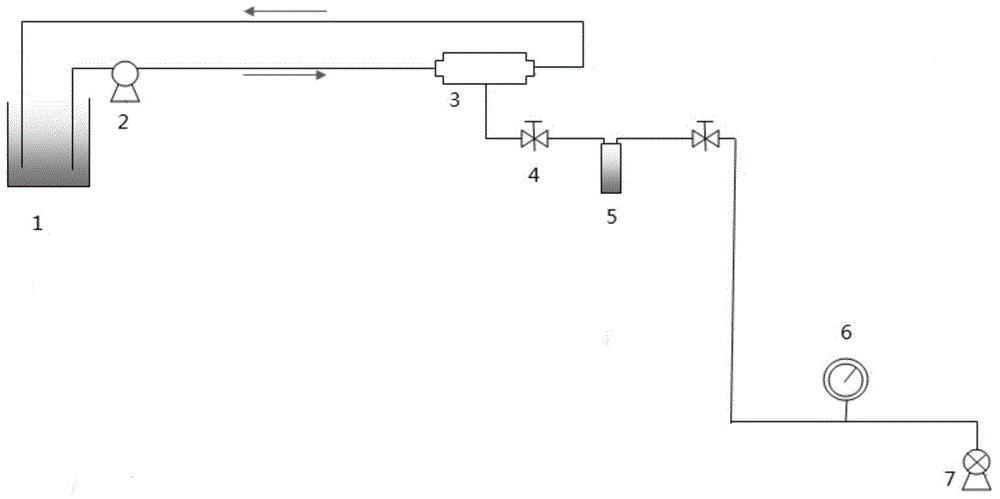

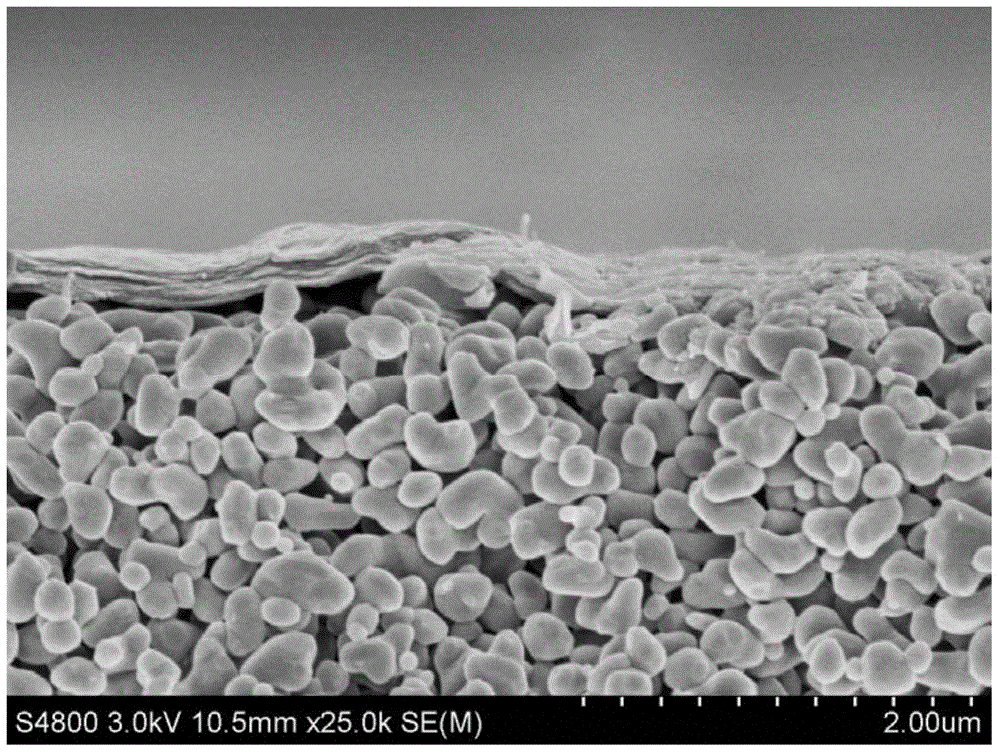

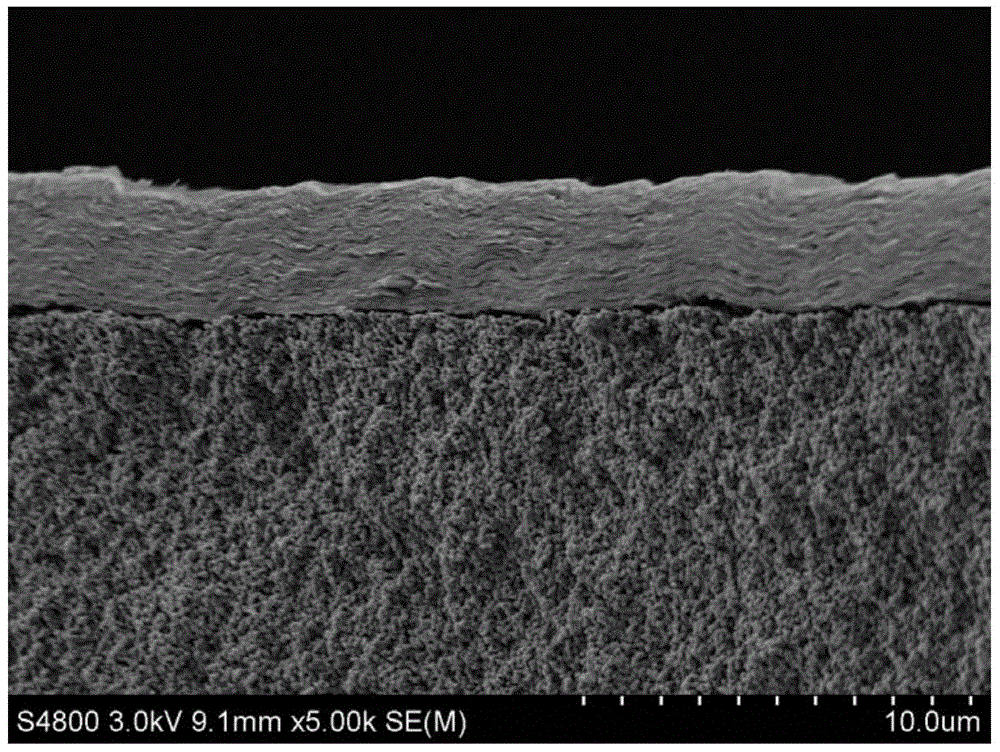

[0037] Example 1 Preparation of graphene oxide membrane on a tubular ceramic carrier for separating a mixture of water and ethanol

[0038] Step 1: Add 100g of deionized water to 1g of graphite oxide and sonicate for 4h at room temperature; centrifuge at 9000rpm for 20min, take the supernatant; add deionized water to the precipitate, sonicate for 20min, and centrifuge under the same conditions. Cycle three times. The obtained clear liquid was centrifuged at 15000 rpm for 60 min, and the precipitate was dissolved in deionized water to form a 2 mg / ml graphene oxide hydrosol.

[0039] Step 2: Select a porous ceramic tube as the carrier. The inner and outer diameters of the porous ceramic tube are 10mm and 7mm, respectively, and the average pore diameter of the inner surface is 100nm. The two ends of the carrier are sealed with glaze, and the effective membrane length is 35mm. After washing, drying, roasting at 500℃ for 1h. The outer surface is sealed with PTFE tape.

[0040] Step 3: ...

Embodiment 2

[0047] Example 2 Preparation of graphene oxide membrane on a ceramic hollow fiber support for separating a mixture of water and isopropanol

[0048] The difference from Example 1 is: in step 1, the concentration of graphene oxide hydrosol is 5mg / ml; in step 2, ceramic hollow fiber is selected as the carrier, the outer side is the selective layer, and the inner and outer diameters are 1.8mm respectively And 1.4mm, the average pore diameter of the inner surface is 50nm, the two ends of the carrier are sealed with glaze, the effective membrane length is 70mm, after washing and drying, roasting at 500℃ for 1h; Step 4, use pervaporation separation process to separate the mixture of water and isopropanol, operation The temperature is 70°C, the system pressure is 0.1MPa, and the feed mass concentrations of isopropanol:water are 90:10, 85:15, and 80:20 respectively. The remaining steps are the same as in Example 1. The separation test results are shown in Table 2:

[0049] Table 2 Test r...

Embodiment 3

[0052] Example 3 Preparation of graphene oxide membrane on a tubular ceramic carrier for separating a mixture of water and o-xylene

[0053] The difference from Example 1 is that in step 1, the concentration of the graphene oxide hydrosol is 0.05 mg / ml; in step 3, pressure assisted deposition is used to install the ceramic tube into the permeation component, and the graphite oxide is introduced from the inside of the membrane tube Alkene hydrosol, with a certain pressure of nitrogen as the driving force, the pressure range is 1-10bar; step 5 adopts the pervaporation separation process to separate water and o-xylene mixture, the operating temperature is 70℃, the system pressure is 0.1MPa, and the feed mass concentration is close to Xylene: water is 90:10, 85:15, 80:20 respectively. The remaining steps are the same as in Example 1. The separation test results are shown in Table 3:

[0054] Table 3 Example 3 o-xylene and water vapor phase permeation separation test results

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com