Nanosilver/graphene oxide composite dispersion fluid, and preparation method and application thereof

A technology of composite materials and graphene, which is applied in the field of nanocomposite materials and its preparation, to achieve the effect of strong repeatability and inhibition of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1) adopt improved Hummers method to prepare graphene oxide, obtain the 0.5mg / ml graphene oxide dispersion liquid of 720ml through drying again;

[0071] 2) Preparation of mixed solution: add ammonia solution to the graphene oxide dispersion to adjust the pH value of the system to 12, and add 20 g of protective agent polyvinylpyrrolidone (PVP) to obtain a mixed solution;

[0072] 3) prepare the 0.05M / L silver nitrate aqueous solution of 60ml;

[0073] 4) First add the mixed solution into the supergravity rotating packed bed reactor, then add the silver salt solution, and react for 10 minutes under the reaction conditions of a temperature of 40°C and a rotation speed of 1500r / min to obtain a nano-silver / graphite oxide composite material;

[0074] 5) Wash the nano-silver / graphite oxide composite material obtained in 4), and then disperse it in water to obtain a 0.5 mg / ml aqueous dispersion of nano-silver / graphite oxide composite material.

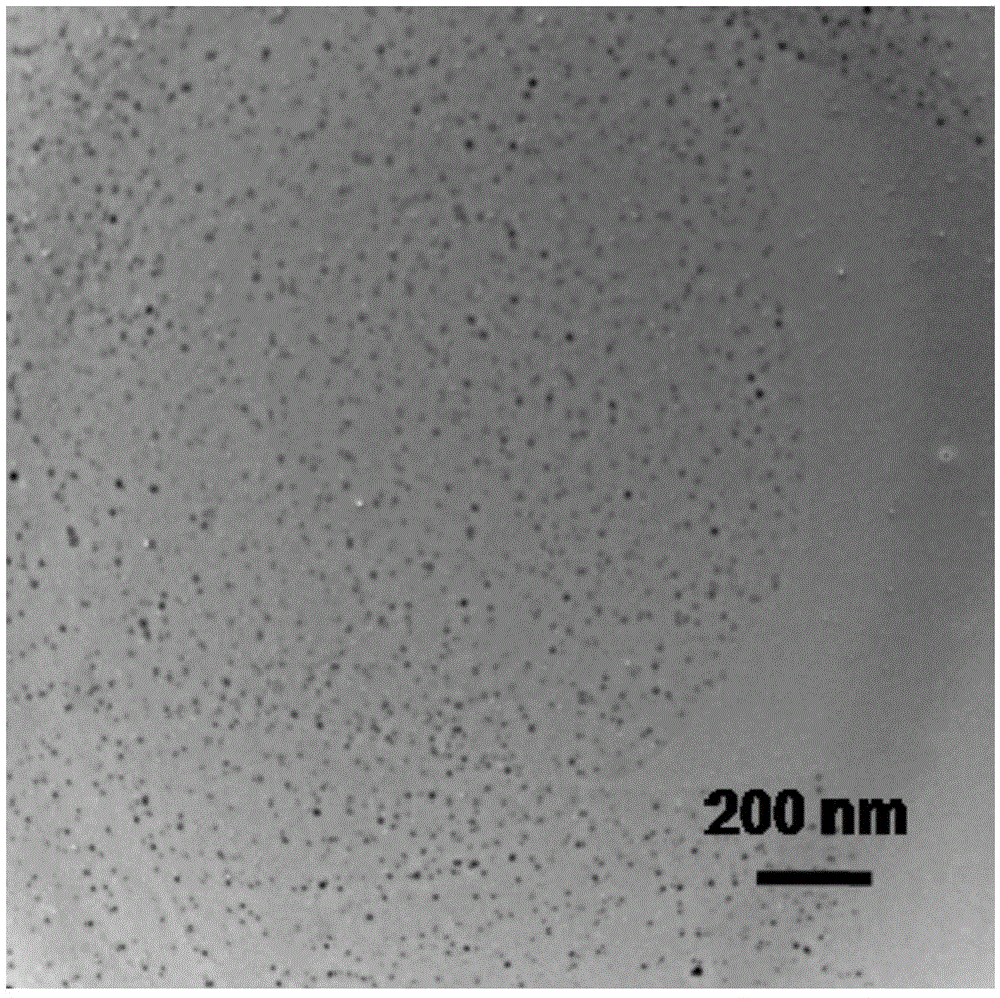

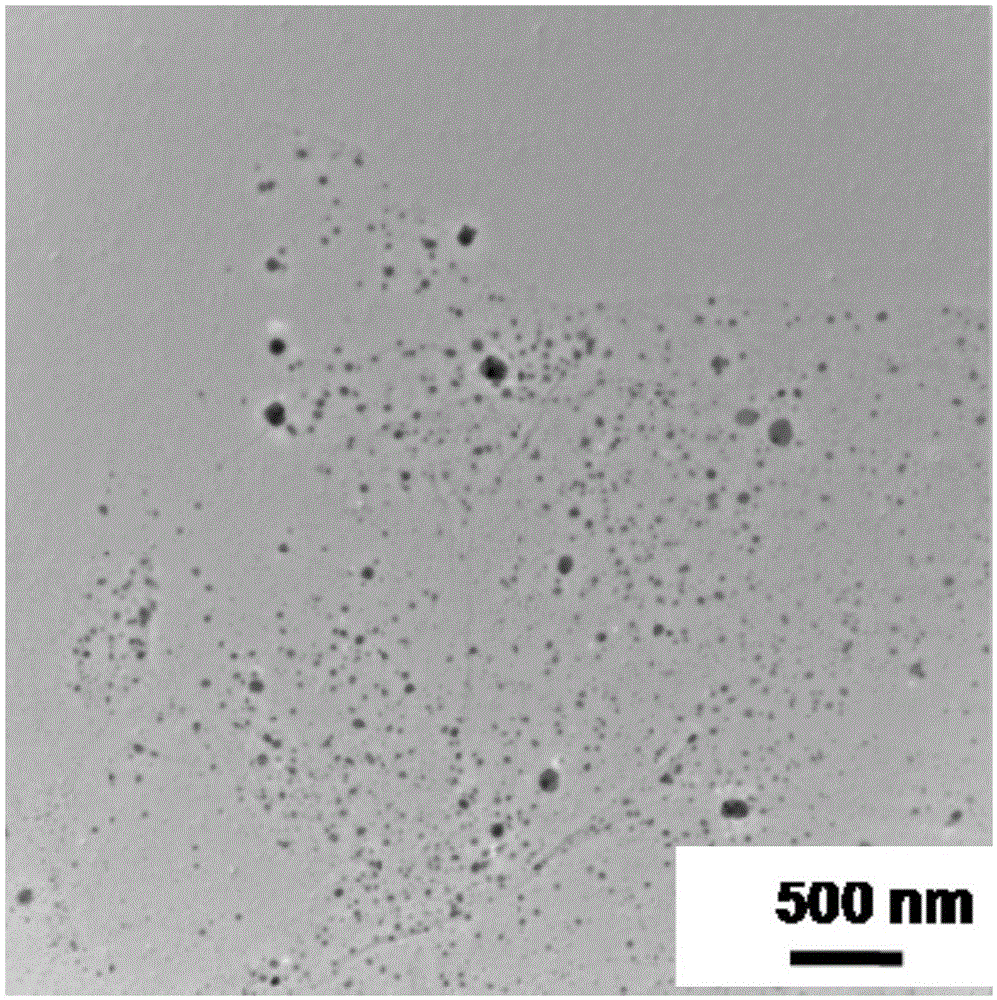

[0075] figure 1 A transmission...

Embodiment 2

[0078] 1) adopt improved Hummers method to prepare graphene oxide, obtain the 2mg / ml graphene oxide dispersion liquid of 720ml through drying again;

[0079] 2) Preparation of mixed solution: add ammonia solution to the graphite oxide dispersion to adjust the pH value of the system to 11; add 20 g of protective agent cetyltrimethylammonium bromide to obtain a mixed solution;

[0080] 3) prepare the 0.05M / L silver acetate aqueous solution of 60ml;

[0081] 4) First add the mixed solution into the supergravity rotating packed bed reactor, then add the silver salt solution, and react for 3 minutes under the reaction conditions of a temperature of 60°C and a rotation speed of 500r / min to obtain a nano-silver / graphite oxide composite material;

[0082] 5) Wash the nano-silver / graphite oxide composite material obtained in 4), and then disperse it in water to obtain a 10 mg / ml aqueous dispersion of nano-silver / graphite oxide composite material.

Embodiment 3

[0084] 1) adopt improved Hummers method to prepare graphene oxide, obtain the graphene oxide dispersion liquid of the 5mg / ml of 720ml through drying again;

[0085] 2) Preparation of the mixed solution: adding a dopamine aqueous solution to the graphite oxide dispersion to adjust the pH value of the system to 8, adding 20 g of protective agent oleic acid to obtain a mixed solution;

[0086] 3) prepare the 0.05M / L silver carbonate aqueous solution of 60ml;

[0087] 4) First add the mixed solution into the supergravity rotating packed bed reactor, then add the silver salt solution, and react for 20 minutes under the reaction conditions of a temperature of 50°C and a rotation speed of 2500r / min to obtain a nano-silver / graphite oxide composite material;

[0088] 5) The nano-silver / graphite oxide composite material obtained in 4) is washed and then dispersed in water to obtain a 0.01 mg / ml aqueous dispersion of nano-silver / graphite oxide composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com