Processing of Single-Walled Carbon Nanotube Metal-Matrix Composites Manufactured by an Induction Heating Method

a carbon nanotube and composite material technology, applied in the field of carbon nanotubemetal composites, can solve the problems of poor thermal and electrical conductivity, poor strength, and general limited use of composite materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0033]The following experimental example is included to demonstrate particular aspects of the present invention. It should be appreciated by those of skill in the art that the methods disclosed in the examples that follows merely represent exemplary embodiments of the present invention. However, those of skill in the art should, in light of the present disclosure, appreciate that many changes can be made in the specific embodiments described and still obtain a like or similar result without departing from the spirit and scope of the present invention.

[0034]The present inventors conducted metallurgy research in an electromagnetic levitation (EML) facility where a conventional conical levitation coil was used.

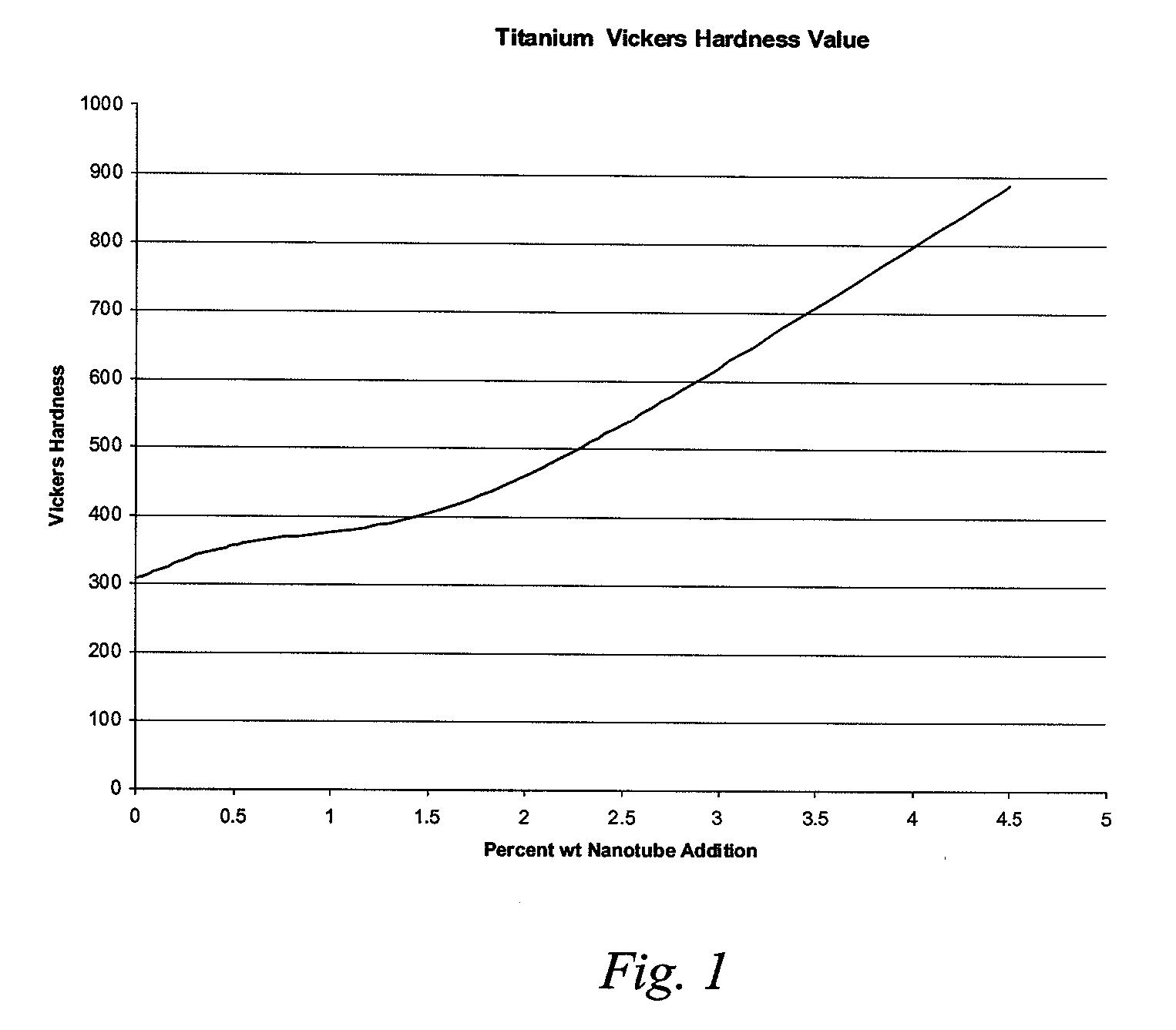

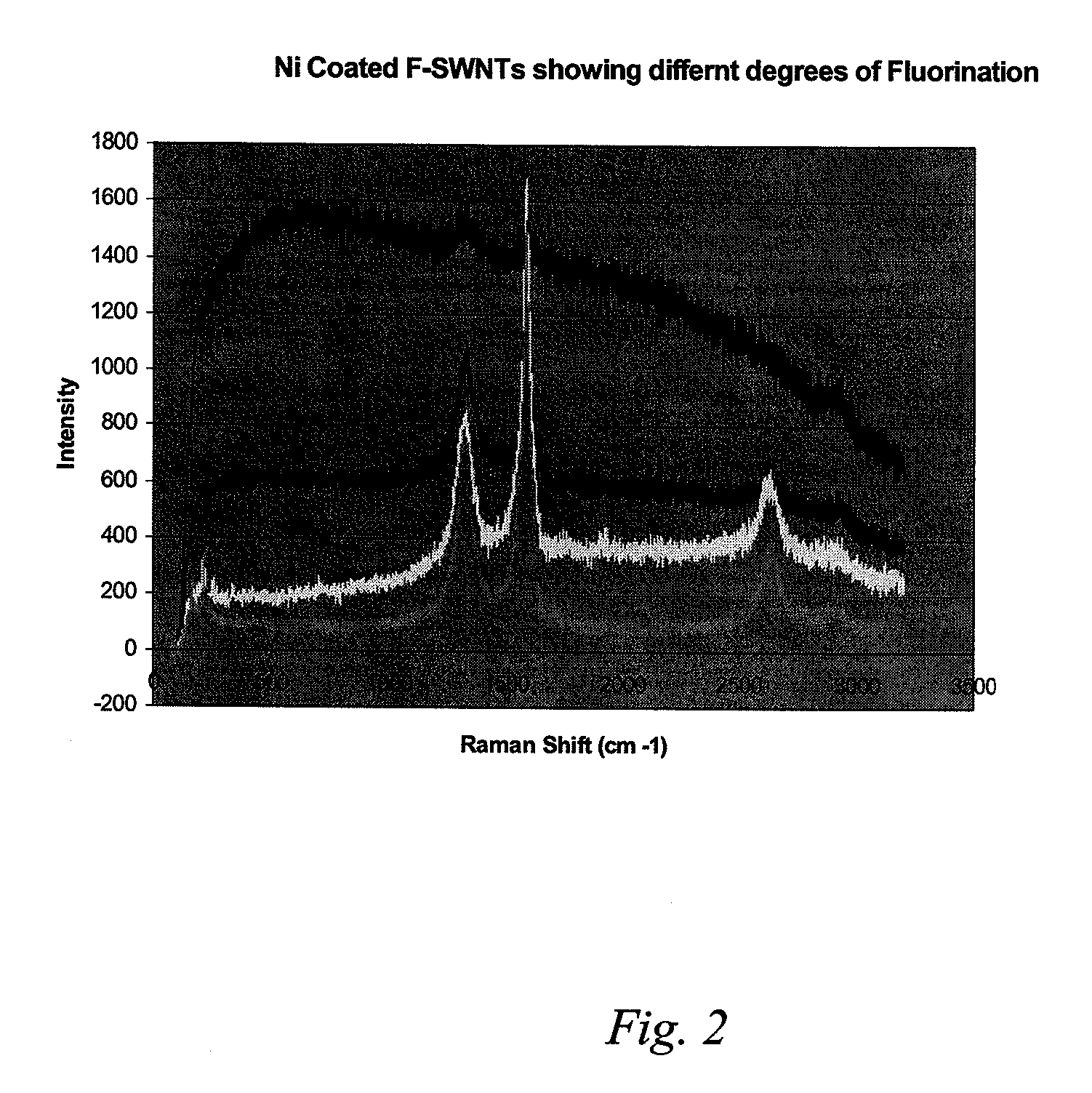

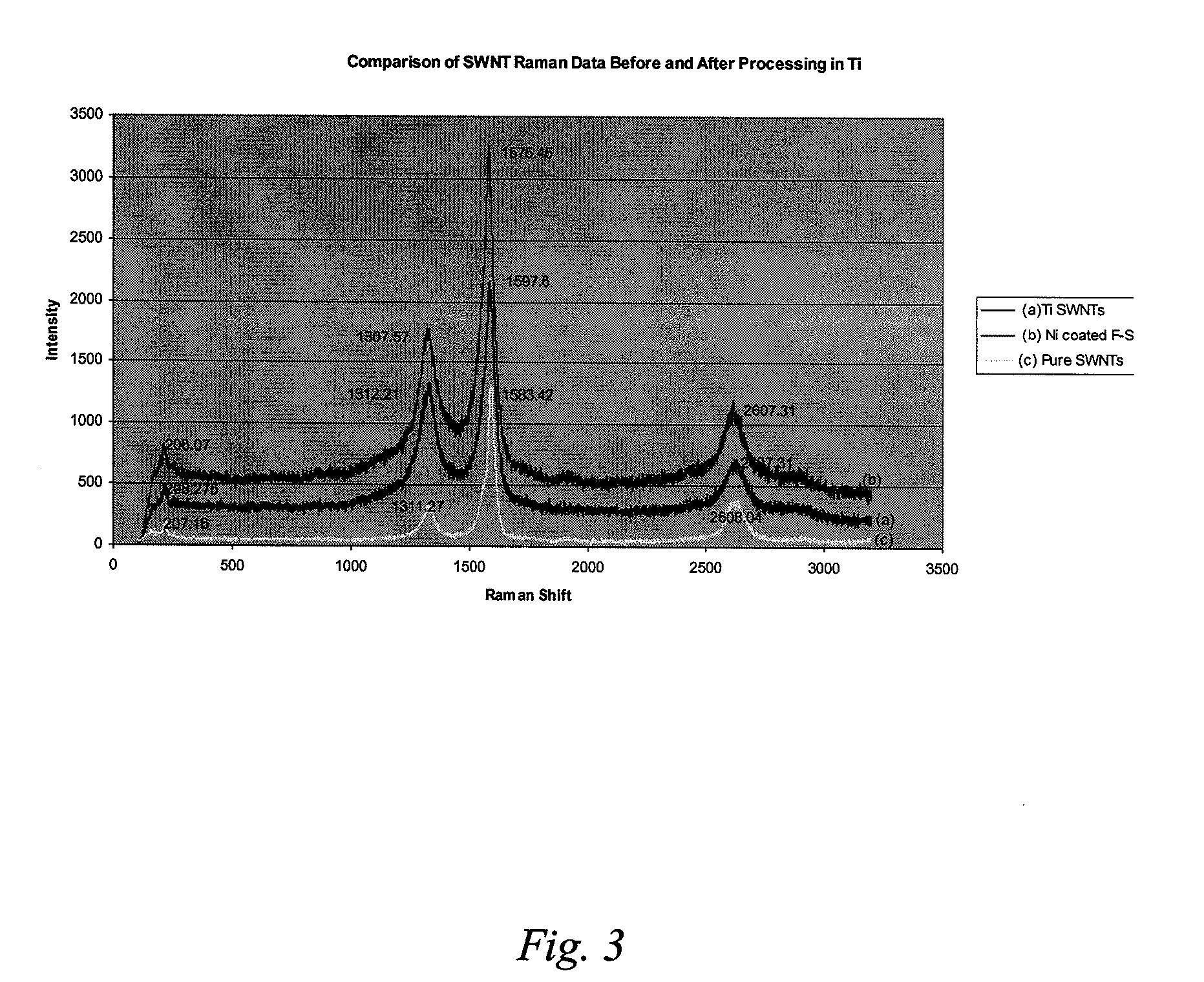

[0035]Induction heating has been chosen as the present method since it provides rapid heat and cooling conditions and short transient times. Heating and melting the metal as fast as possible minimizes the possibility of the SWNTs changing morphology or chemically reacting with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com